Method for production of N, N dimethyl cyclohexylamine

A technology of dimethylcyclohexylamine and its production method, which is applied in chemical instruments and methods, reductive alkylation preparation, organic compound/hydride/coordination complex catalyst, etc., which can solve the problem of unsatisfactory product color and production cost high production energy consumption and other problems, to achieve the effect of increasing the layered dehydration rate, reducing production energy consumption and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

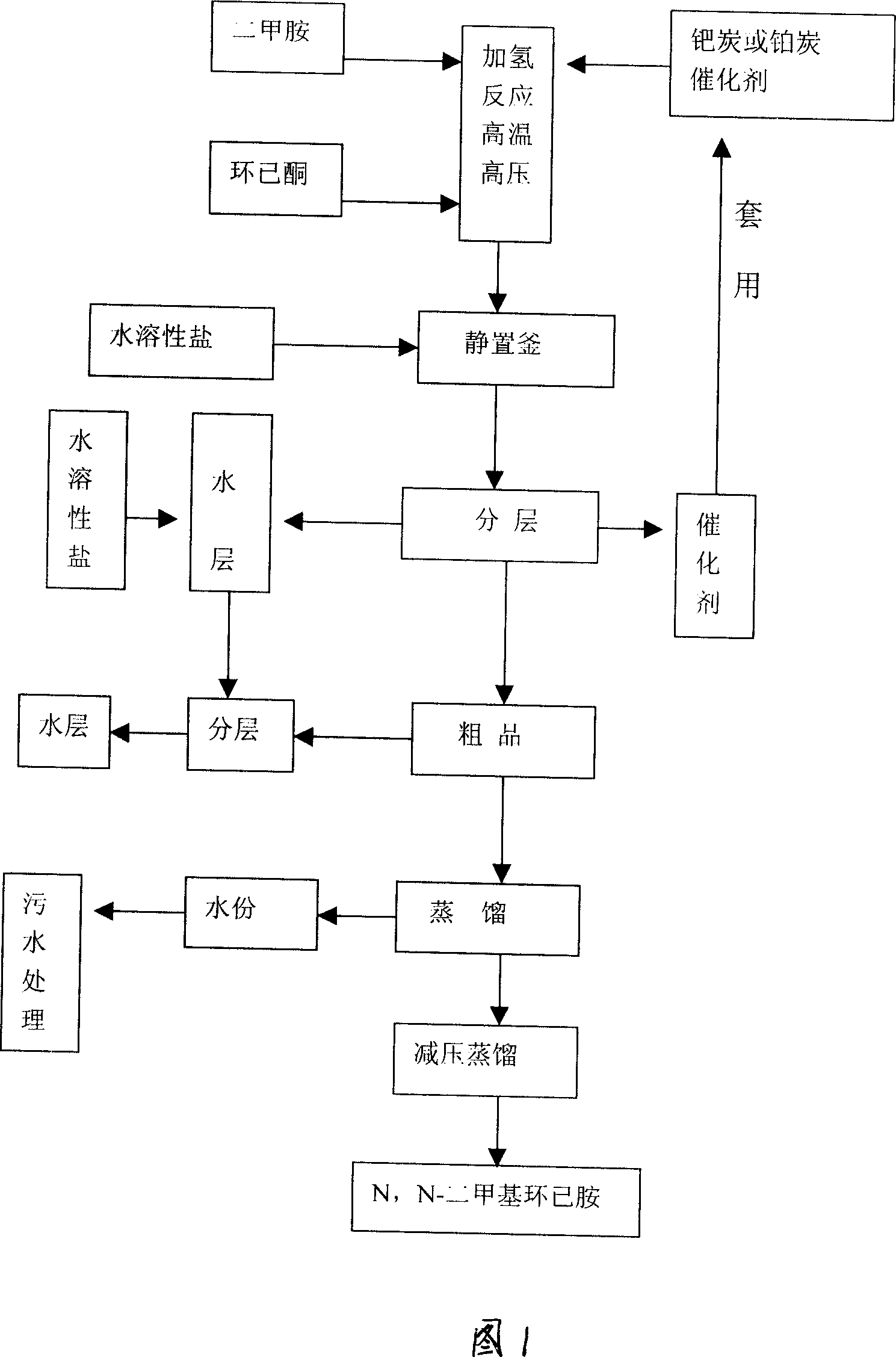

Image

Examples

Embodiment Construction

[0013] The following example illustrates the specific preparation method of N, N-dimethylcyclohexylamine:

[0014] The first step: put 180 kg of industrial cyclohexanone with a content of 98% and 207 kg of an aqueous solution of dimethylamine with a content of 27% into an autoclave, add an appropriate amount of catalyst palladium carbon or platinum carbon, stir and mix evenly, and then heat up to 140-160 ℃, feed hydrogen, the pressure is 2-4.5Mpa, and fully react for 3-6 hours to obtain 390 kg of a mixture of N,N-dimethylcyclohexylamine and water;

[0015] The second step: 390 kilograms of N,N-dimethylcyclohexylamine and water mixture obtained in the above steps are put into a still kettle, add 40 kilograms of sodium chloride, stir and dissolve and let stand to make N,N-dimethylcyclohexylamine Most of the water layer in the mixture of the hexylamine crude product, thereby most of the water is separated and discharged, and 240 kilograms of N, N-dimethylcyclohexylamine catalyst ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com