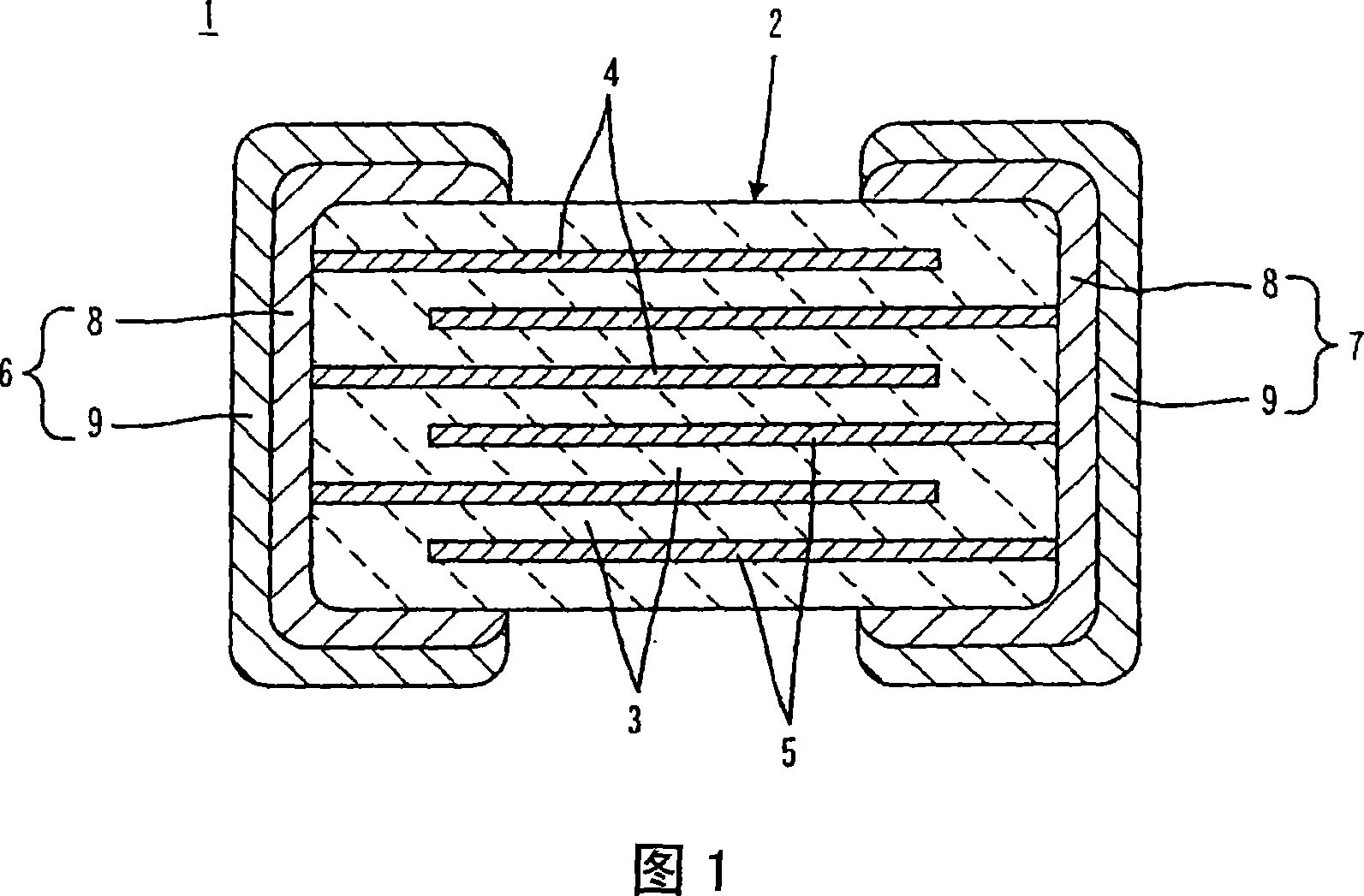

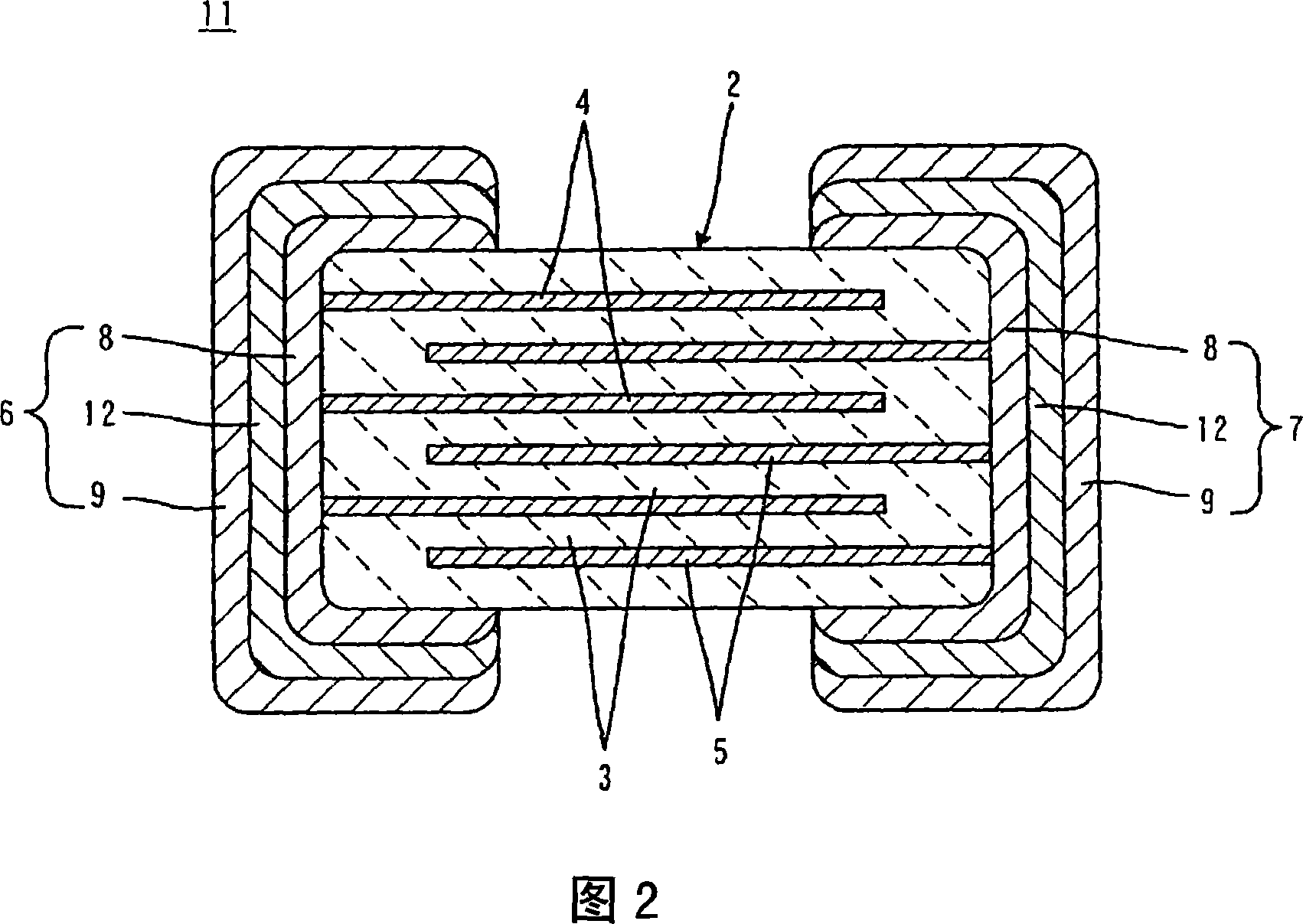

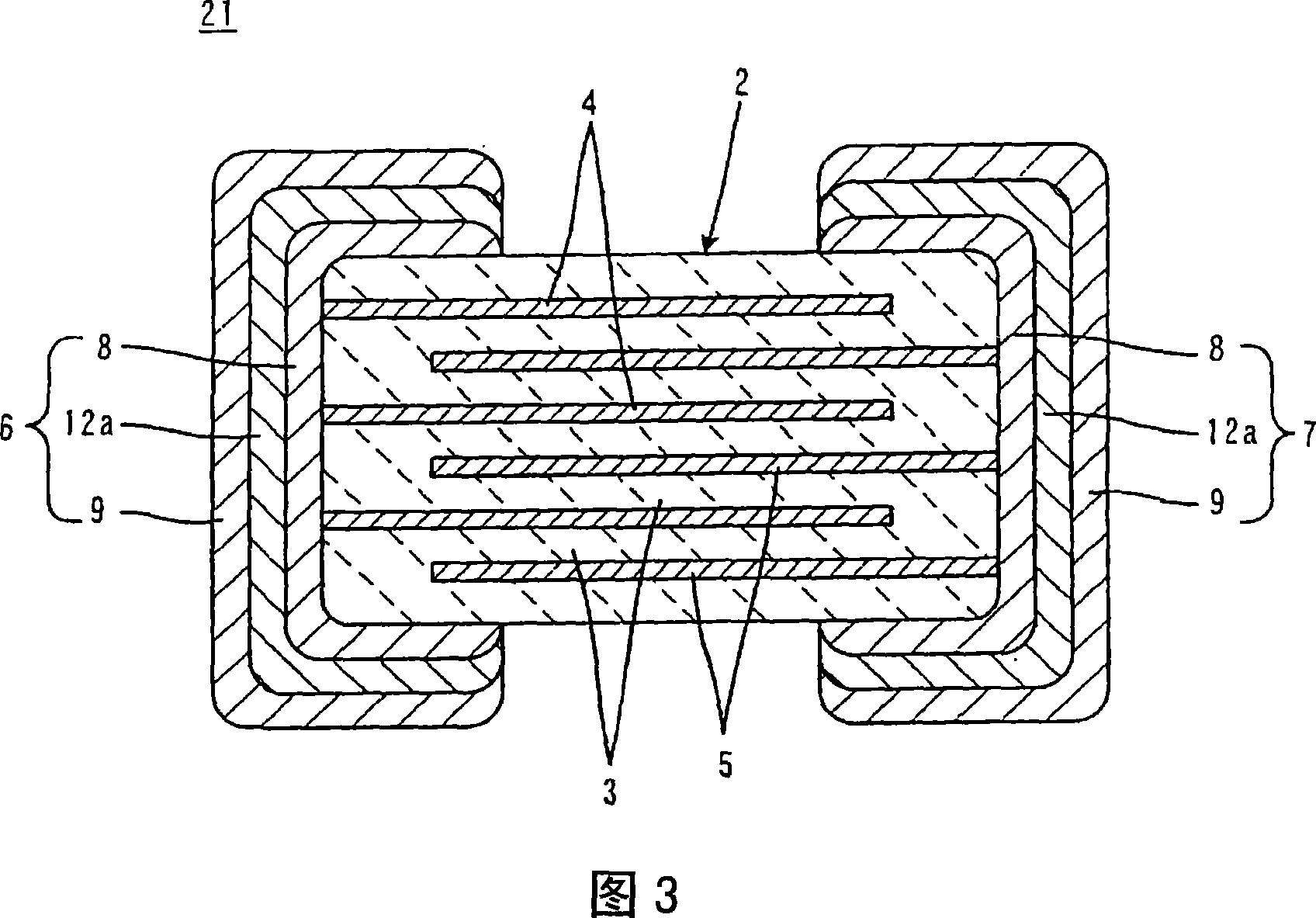

Multilayer ceramic capacitor and method for controlling equivalent series resistance

A technology of equivalent series resistance, ceramic capacitors, applied in the direction of multilayer capacitors, fixed capacitor dielectrics, capacitors, etc., can solve the problems of high electrical connection state, high price, inability to obtain reliability, etc., to ensure weather resistance, avoid thickness The effect of increasing, good weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0090] Experimental Example 1 was carried out to confirm the effects of composite oxides reacting with Ni and Ni alloys, especially In-Sn composite oxides and La-Cu composite oxides, which are characteristic configurations of the present invention.

[0091] First, a capacitor body for a multilayer ceramic capacitor designed to contain Ni in its internal electrodes and have a capacitance of 1 μF was prepared by a known method.

[0092] On the other hand, in order to form a conductive layer containing a resistance component, in an example within the scope of the present invention, a paste for a conductive layer was produced as follows.

[0093] First, in the example including the In-Sn composite oxide, according to the SnO 2 powder relative to In 2 o 3 Powder and SnO 2 The total amount of powder is at a content rate of 5% by weight, in In 2 o 3 Mixed SnO in powder 2 powder, temporarily sintered at 1400 °C for 5 hours in the atmosphere, and the SnO 2 After sufficient solid...

experiment example 2

[0108] Experimental Example 2 was carried out to confirm that the ESR of the multilayer ceramic capacitor can be adjusted according to the addition amount of the glass component contained in the conductive layer, the glass softening point, and the addition amount of the conductive metal component.

[0109] (1) ESR adjustment based on the amount of glass components added

[0110]In the above-mentioned Experimental Example 1, in the paste for the conductive layer containing the In-Sn composite oxide prepared as an example, the volume ratio of "In-Sn composite oxide": "glass" was 1:1 (5:5 ), but in addition, the paste for the conductive layer that adopts the volume ratio of 8:2 and the paste for the conductive layer that adopt the volume ratio of 7:3 are produced respectively, and by the same method as the case of Test Example 1, it is made as For the multilayer ceramic capacitors of the samples, ESR was measured on average for 10 samples, the average value and standard deviation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com