Bi-metal foil for a beam intensity/position monitor, method for determining mass absorption coefficients

a beam intensity/position monitor and bi-metal foil technology, applied in the direction of optical radiation measurement, instruments, photomechanical equipment, etc., can solve the problems of inability to meet all cross-section requirements through printed tables, unstable electronic structure of atoms, and time-consuming manual switching of foils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

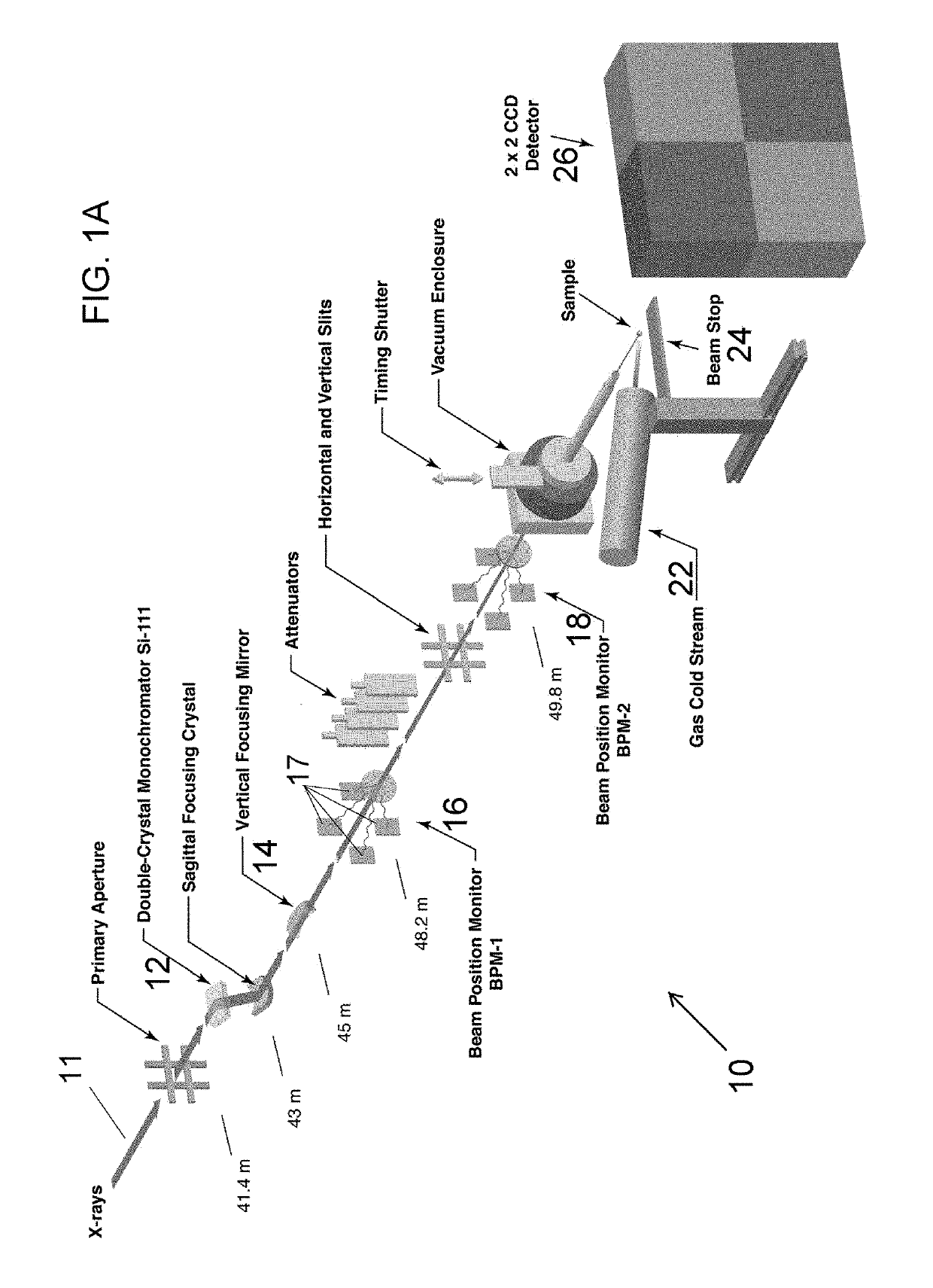

[0079]All measurements were conducted at the Structural Biology Center, bending beamline, 19BM, at the Advanced Photon Source at Argonne Laboratory, Lemont, Ill. Turning to FIG. 1A, the 19BM optics include a Si(111) double-crystal monochromator, a water cooled first crystal with liquid gallium interface, sagittal focusing second crystal web: 25 mm×75 mm×0.58 mm (width×length×thickness), and vertical focusing ultra low expansion glass mirror with Pd, Pt and glass lanes.

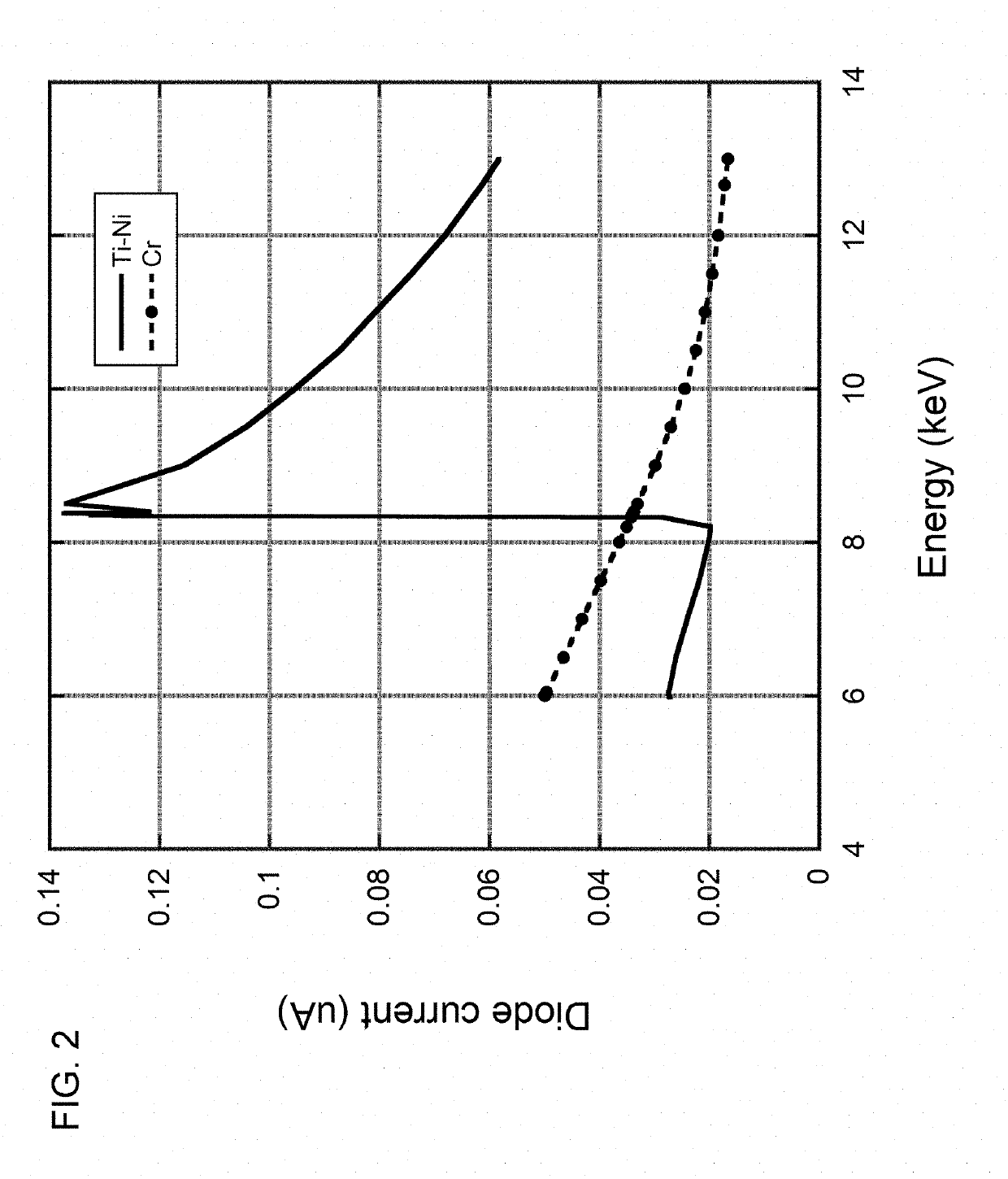

[0080]Downstream of the mirror is the first beam position monitor, BPM-1, which containing the above-described Ti—Ni bi-metal foil. A pneumatic plunger allows the foil holder to move completely out of the beam path. A second beam position monitor, BPM-2, is a fixed (non-movable) foil position containing a nominal 0.5 μm-Cr foil made by Arizona Carbon Foil Co. (2239-T E. Kleindale Rd, Tucson Ariz. 85719, USA). Separation distance between BPM-1 and BPM-2 is 1.6 m. All photodiodes are operated in the unbiased, photovoltai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| energy absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com