If a formation's

porosity is low, meaning that the pores are not sufficiently interconnected, the fluids cannot migrate through the formation and, thus, cannot be brought to the earth's surface without a structural modification or stimulation of the production zone.

This previously proposed perforation and proppant fracturing technique has several well known and heretofore unavoidable problems, limitations and disadvantages.

For example, when the proppant

slurry discharge member is lowered into the well bore, it is difficult to obtain a precise alignment (in both the axial and angular directions) between the

discharge ports in the

discharge member and the perforations in the casing.

The usual result is that some degree of misalignment exists between the discharge ports and the perforations.

Use of the above-described prior technique also limits the ability to isolate multiple production zones from one another--a requirement that may be necessary due to the fact that different zones may require different fracturing pressures, different types of fracturing fluids, and different amounts of proppant.

In many such operations, however, the results were not satisfactory.

Thus, because little fracing fluid actually enters the other zones when this occurs, certain potentially productive zones are not adequately stimulated or fraced, and do not thereafter produce to the desire degree.

The method thus described, however, has inherent limitations.

Turbulence caused by the

abrasive fracing fluid flowing back into the annulus creates a pressure differential across the packers and tends to erode or "wash out" and ruin the packer

assembly, an event that frustrates the fracturing operation.

If the packers are set on those gaps, then the packers will not seal properly and hold pressure to isolate the intended interval.

This condition can cause the packers to wash out and erode.

Further, depositing large quantities of proppant above the packer

assembly may cause the

assembly to stick in the hole or to otherwise become difficult to relocate.

Unfortunately, properly positioning the packers with respect to the perforations and casing joints has been difficult to achieve.

For deep wells, depth control is more problematic.

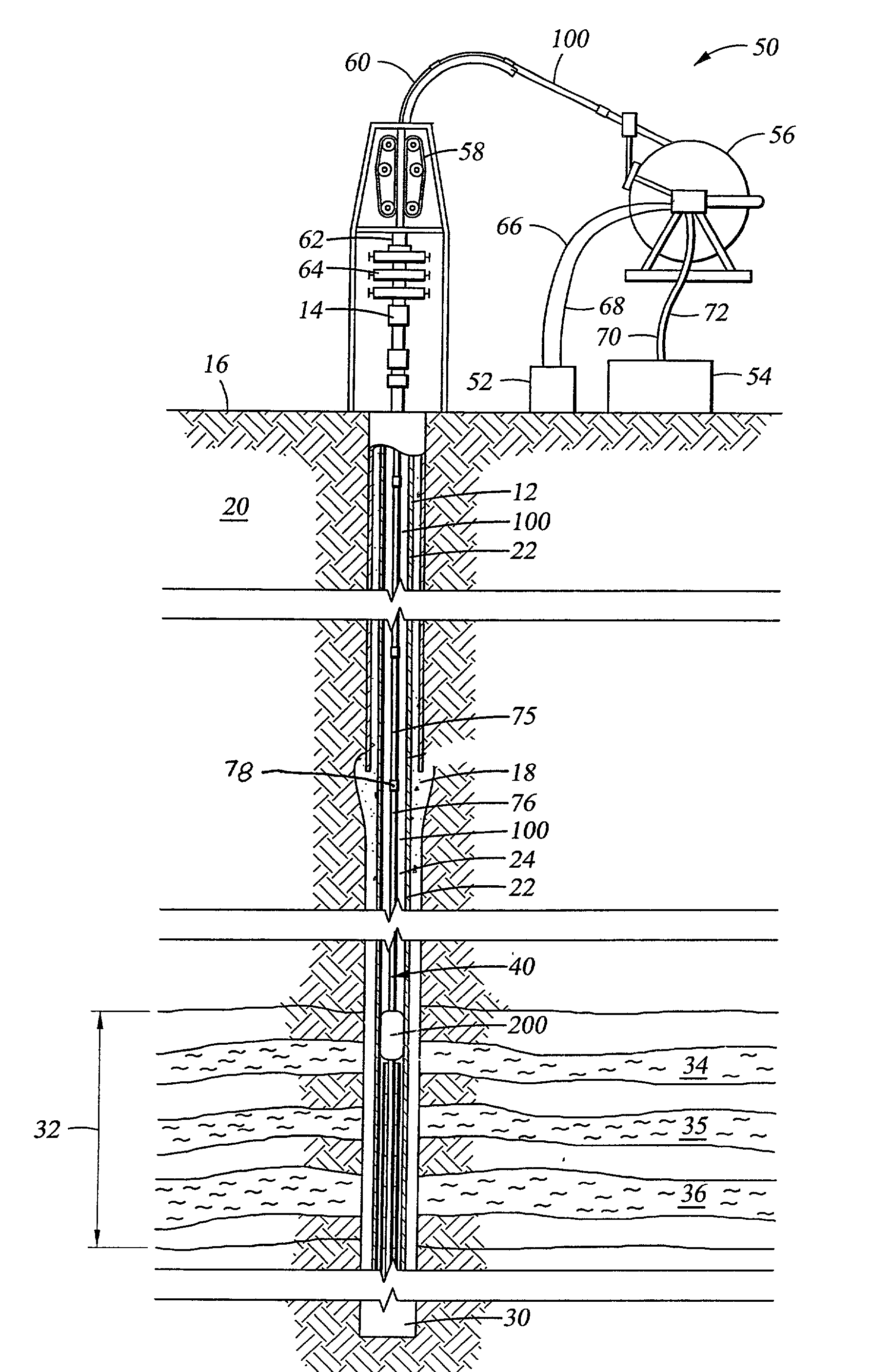

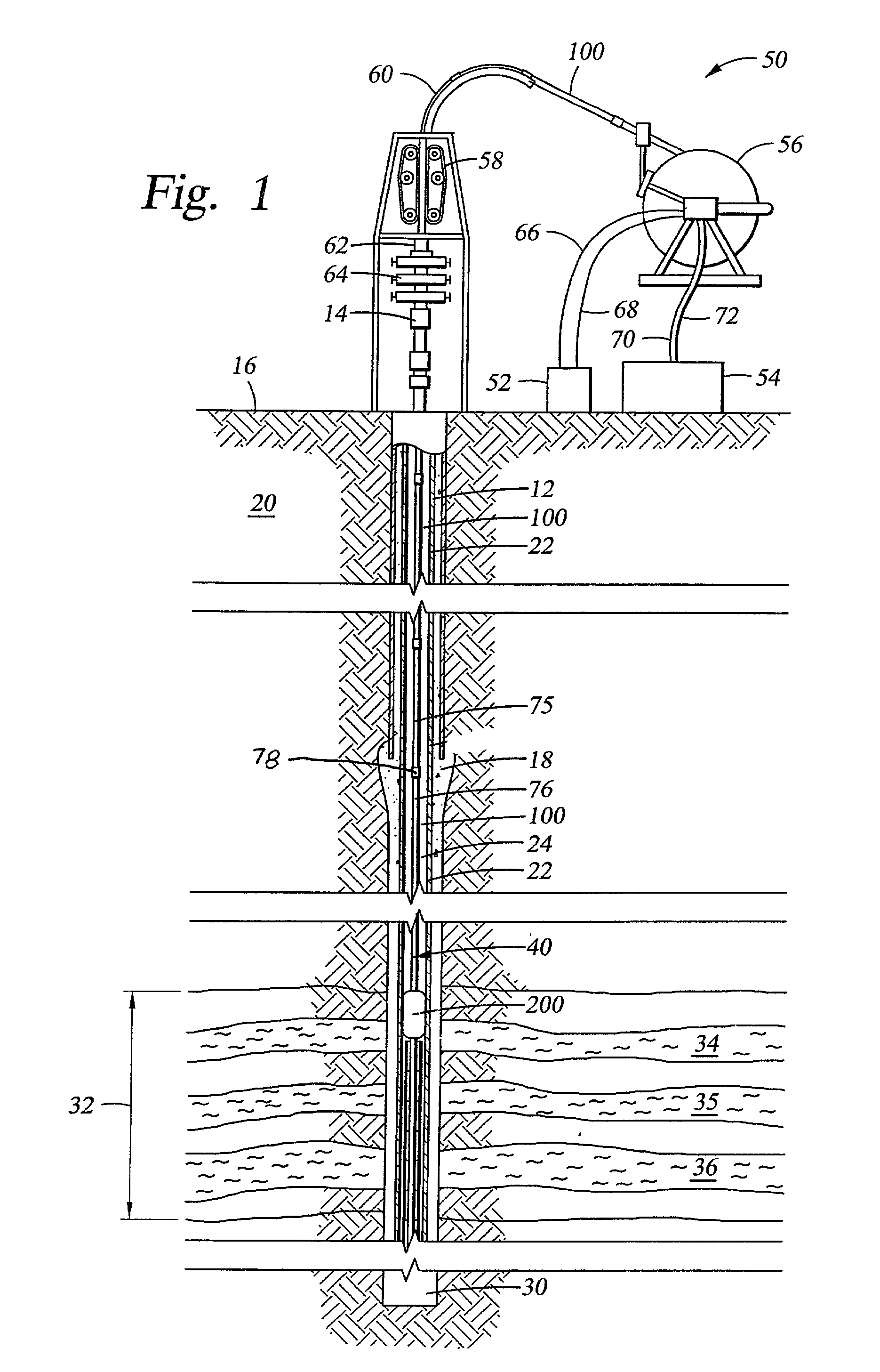

For example, if the work string is jointed

pipe, the weight of the work string extending into a deep well tends to cause the string to stretch such that its length, and thus the location of the downhole tool it supports, may not provide an accurate depth indication.

Further, the work string will tend to expand and contract with downhole temperatures which also introduces inaccuracies in the length of the string and thus the actual depth of the tools.

In another example, when the workstring is

coiled tubing and it is run into a deep well, it tends to bend and curl within the cased borehole, such that the exact distance from the surface to the downhole tool does not equal the length of

coiled tubing that has been injected into the well.

Using closely-spaced

straddle packers in a deep well however, and considering the expansion and contraction of the

coiled tubing, as well as the tendency for the coiled tubing to bend and curl in the borehole, it is extremely difficult to determine exactly where the packers and fracing assembly are in relation to casing joints and the perforations.

Although conventional

metal coiled tubing has been employed in shallow wells in certain fracing operations, it is not feasible in certain deep wells.

For example, most conventional

metal coiled tubing cannot withstand a 12,000 psi

differential pressure as may be encountered at the surface when conducting deep well fracing operations.

Further,

metal coiled tubing is relatively heavy and transporting the number of spools of coiled tubing required for the operation and injecting and withdrawing the tubing from a deep well requires specially designed,

heavy duty equipment

Furthermore, even if the depth of the fracing assembly were somehow to be precisely known, there still exist problems that are introduced due to inaccuracies in determining the actual depth of the perforations.

As stated above, the step of perforating the well typically includes recording the depth and location of the perforations; however, using perforation equipment with wire line, jointed pipes and coiled tubing nevertheless does not always provide accurate depth measurements, due again to the tendency of the

wireline,

pipe and tubing to expand with weight and downhole temperatures, and to bend or coil in the borehole.

Another problem inherent in fracing operations in deep wells raises significant safety concerns.

When screen out occurs without warning, a potentially hazardous condition is created at the surface where the fracing fluid is continuing to be pumped through the work string at very high pressures, such as from 5,000 to 18,000 psi.

When the downhole pressure suddenly spikes, the

differential pressure as measured across the wall of the work string at the surface may exceed the

margin of safety causing the

pipe to burst, subjecting personnel and equipment to risk.

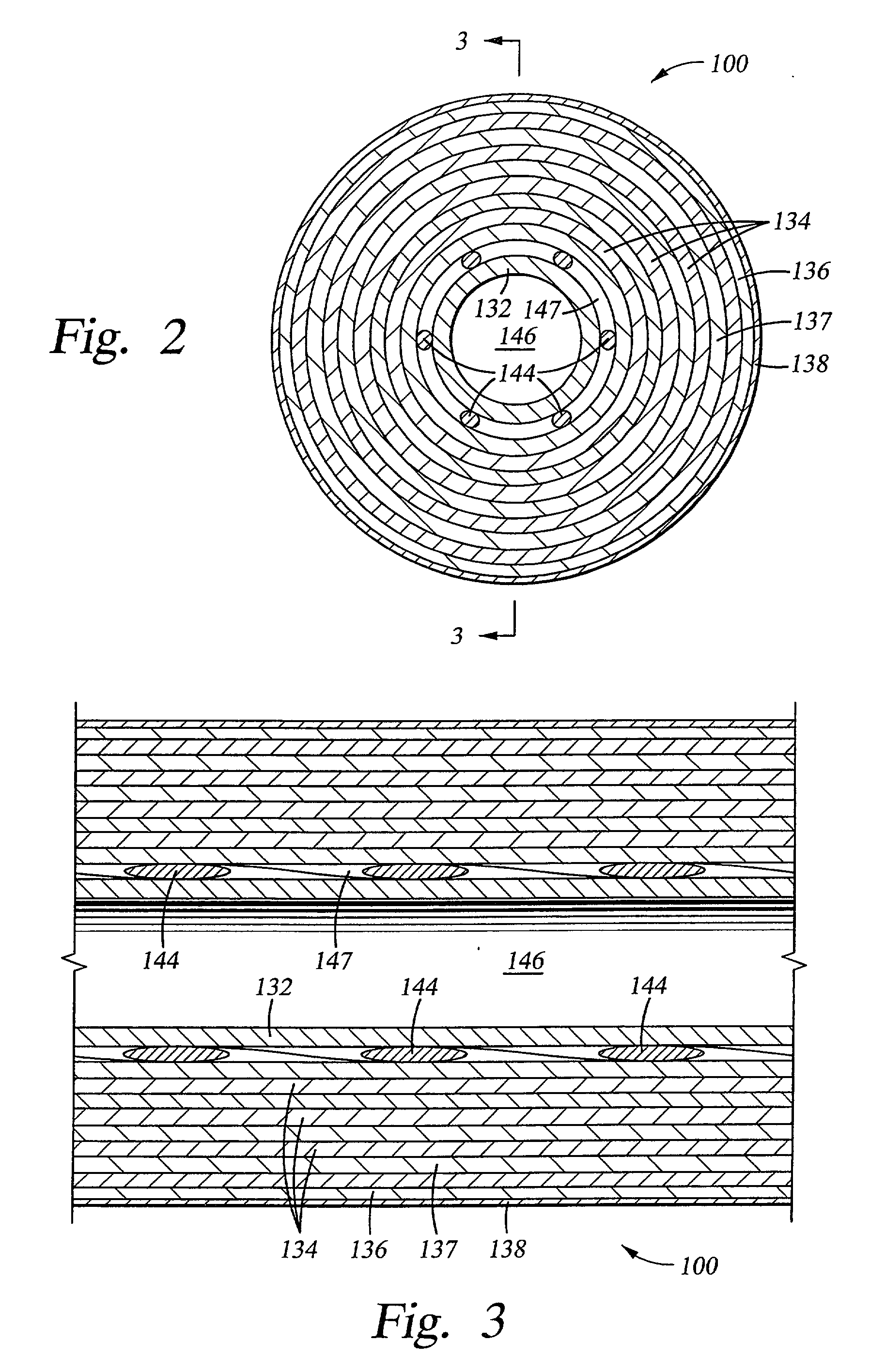

Positioning a

pressure sensor in the workstring adjacent to the discharge sub to sense downhole pressure and communicate the

pressure data to the operator or controller at the surface would be advantageous; however, communicating data to the surface during fracing operations has presented a problem.

Although it is common to use mud pulse

telemetry in well operations for transmitting data to a surface controller, mud pulse

telemetry is difficult if not impossible to employ in fracing operations because there is too much hydrostatic

noise which prevents transmission of

telemetry up the annulus to the surface.

Further, although electrical signals can be sent uphole via conductors strapped on the outside of the work string, the conductors are subjected to abuse and damage as the work string scraps against the sides of the well bore while the workstring is lowered into or removed from the bottom of the

wellbore, and as well fluids flow around the conductors.

However, for several reasons, it is extremely difficult to extrapolate the downhole pressure from the measured

surface pressure and the other available data, particularly in deep well operations.

Thus, the weight of fluid being pumped downhole increases as the process continues over time.

These changing variables, coupled with the high volume of fluid that is pumped during the fracing operation, makes calculating the downhole pressure very complex.

The fluids and their

density change so fast that it is difficult if not impossible to calculate accurately downhole pressure.

Once again, if the downhole pressure spikes quickly and the spike cannot be seen or predicted soon enough based on the pressures calculated at the surface, the excessive pressure can cause the work string to burst, endangering both

crew and equipment.

The fact that the fracing fluid is in two phases and that the volume of gas changes continuously as the fluid moves down into the well bore also makes it even more difficult to calculate

bottom hole pressure.

Unfortunately, when the fracing operation includes pumping proppant downhole, this prior method of employing a wire line

communication link is not believed to be viable because of

erosion to the conductors that occurs at the well head where the proppant is injected, and because of the danger of proppant building-up around the downhole tilt sensors which might cause the downhole assembly to become stuck.

Login to View More

Login to View More  Login to View More

Login to View More