Mesoporous silica particles and production process thereof

a technology of mesoporous silica and production process, which is applied in the direction of silicon oxides, silicon compounds, coatings, etc., can solve the problems of reduced material value, difficult to use it as catalyst support or separation agent, and uniform mesopore size, etc., and achieves high yield and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

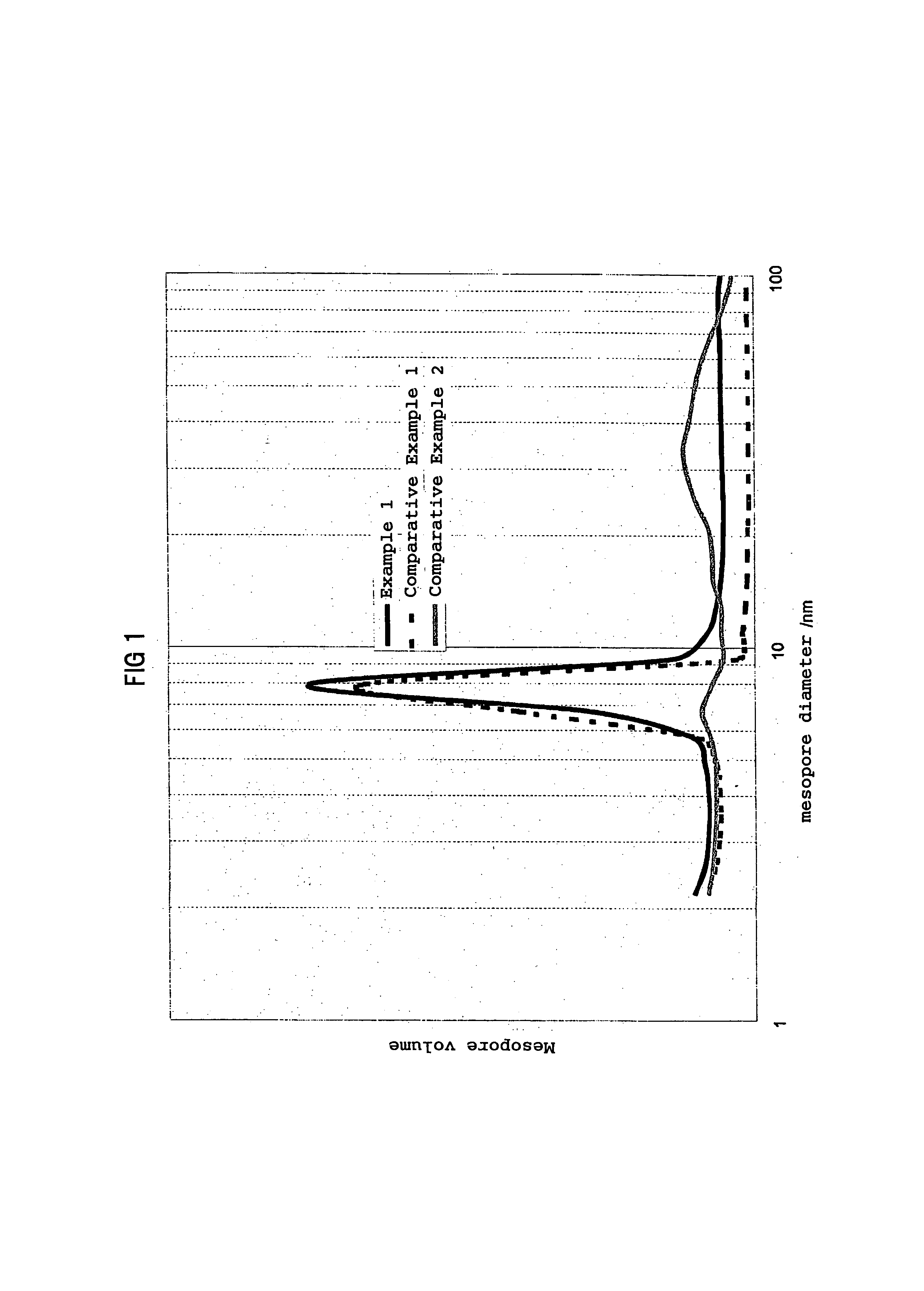

Image

Examples

example 1

[0116] A block copolymer of ethylene glycol and propylene glycol (Pluronic-P123 of BASF Co., Ltd.) was dissolved in ion exchange water to prepare a 20 wt % surfactant solution. 150 g of the surfactant solution, 44 g of 25 wt % sulfuric acid and 73 g of ion exchange water were mixed together to prepare a transparent solution. 133 g of sodium silicate (containing 15 wt % of SiO2 and 5.1 wt % of Na2O) was added dropwise to this solution under stirring to obtain a cloudy reaction mixture. The pH of the reaction mixture was 2.7.

[0117] The reaction mixture was maintained at 30° C. for 1 hour under stirring, heated at 95° C. and maintained at that temperature for 12 hours to produce mesoporous silica particles having the surfactant existent in mesopores.

[0118] Thereafter, a polyethylene pot was filled with 390 g of the above reaction mixture and 1,520 g of zirconia balls having a diameter of 2 mm and sealed up without a dead volume in the pot to wet pulverize the mixture with a pot mill....

example 2

[0135] A block copolymer of ethylene glycol and propylene glycol (Pluronic-F127 of BASF Co., Ltd.) was dissolved in ion exchange water to prepare a 10 wt % surfactant solution. 210 g of the surfactant solution, 59 g of 25 wt % sulfuric acid and 291 g of ion exchange water were mixed together to prepare a transparent solution. 140 g of sodium silicate (containing 15 wt % of SiO2 and 5.1 wt % of Na2O) was added dropwise to this solution under stirring to obtain a cloudy reaction mixture. The pH of the reaction mixture was 1.0.

[0136] The reaction mixture was maintained at 30° C. for 10 hours under stirring, heated at 80° C. and maintained at that temperature for 12 hours to produce mesoporous silica particles having the surfactant existent in mesopores.

[0137] Thereafter, part of the solution was removed from the above reaction mixture by decantation, and the content of the mesoporous silica particles in the reaction mixture was adjusted to 5 wt %.

[0138] A polyethylene pot was filled...

example 3

[0155] A block copolymer of ethylene glycol and propylene glycol (Pluronic-P123 of BASF Co., Ltd.) was dissolved in ion exchange water to prepare a 20 wt % surfactant solution. 100 g of the surfactant solution, 44 g of 25 wt % sulfuric acid and 123 g of ion exchange water were mixed together to prepare a transparent solution. 133 g of sodium silicate (containing 15 wt % of SiO2 and 5.1 wt % of Na2O) was added dropwise to this solution under stirring to obtain a cloudy reaction mixture. The pH of the reaction mixture was 2.7.

[0156] The reaction mixture was maintained at 30° C. for 10 hours under stirring to produce mesoporous silica particles having the surfactant existent in mesopores.

[0157] Thereafter, a polyethylene pot was filled with 390 g of the above reaction mixture and 1,520 g of zirconia balls having a diameter of 2 mm and sealed up without a dead volume in the pot to wet pulverize the mixture with a pot mill. The amount of the surfactant existent in the mesopores was 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com