Semiconductor device having a thin film capacitor and method for fabricating the same

a technology of thin film capacitor and semiconductor device, which is applied in the direction of transistors, coatings, instruments, etc., can solve the problems of high temperature process, deterioration of transistors in logic section, and inability to raise process temperature, and achieve small leakage current and large capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

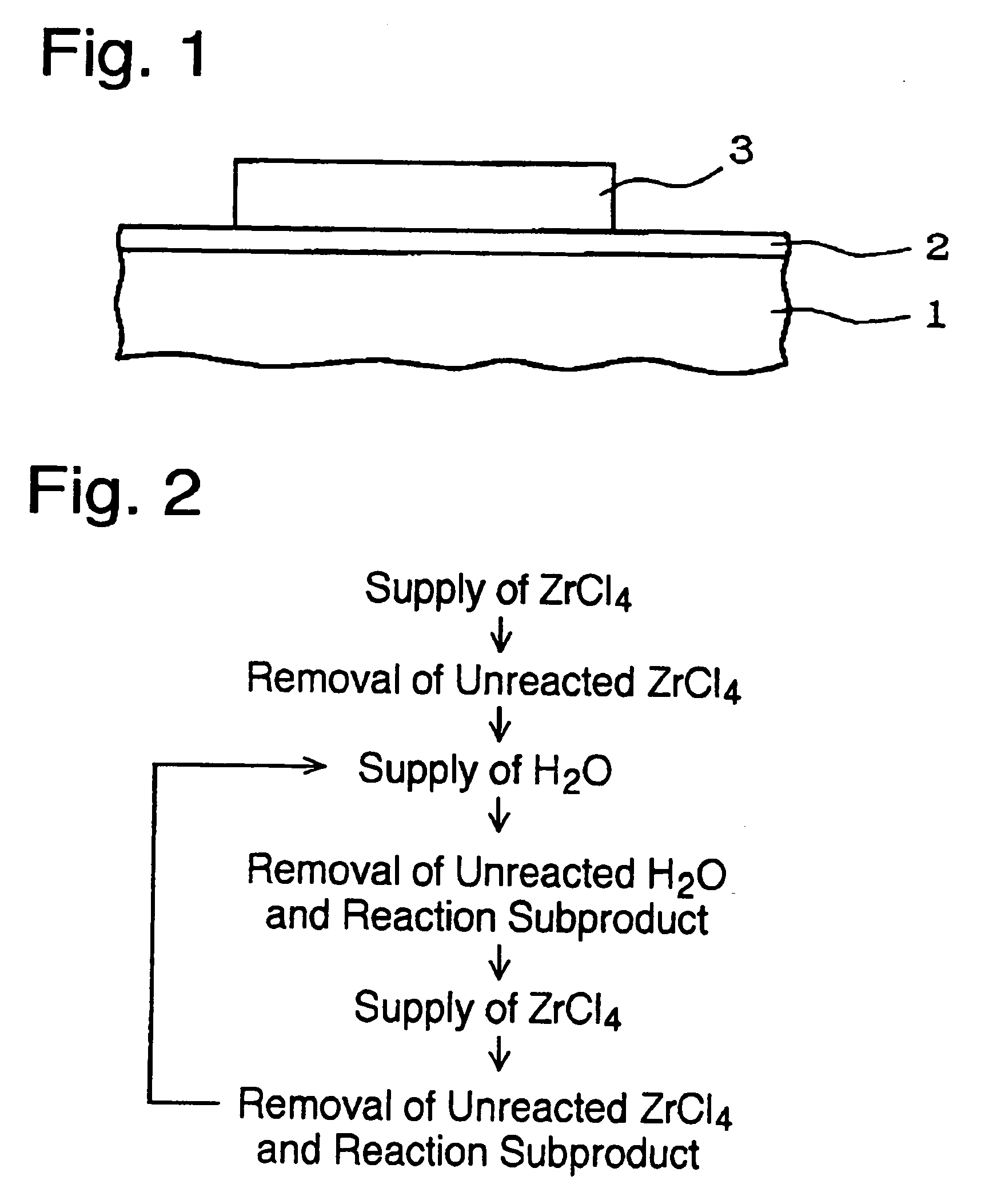

[0049] The first embodiment is a thin film capacitor of a MIM (metal-insulator-metal) structure, provided in a semiconductor device. This thin film capacitor includes a lower electrode 1, a capacitor dielectric film 2 and an upper electrode 3 stacked in the named order. Each of the upper electrode 3 and the lower electrode 1 is formed of at least one material selected from the group consisting of a metal and a metal nitride, represented by TiN, Ti, W, WN, Pt, Ir, Ru. The capacitor dielectric film 2 is formed of at least one material selected from the group consisting of ZrO2, HfO2, (Zrx, Hf1-x)O2 (0y, Ti1-y)O2 (0z, Ti1-z)O2 (0k, Til, Hfm)O2 (01, m<1, k+l+m=1), and formed by means of an atomic layer deposition (abbreviated to “ALD”).

[0050] Here, (Zrx, Hf1-x)O2 (0y, Ti1-y)O2 (0z, Ti1-z)O2 (0k, Til, Hfm)O2 (0<k, l, m<1, k+l+m=1) is an oxide of a solid solution of Zr, Ti and Hf.

[0051] Here, a method for forming the thin film capacitor in the case that the capacitor dielectric film is f...

second embodiment

[0068] Now, the present invention will be described.

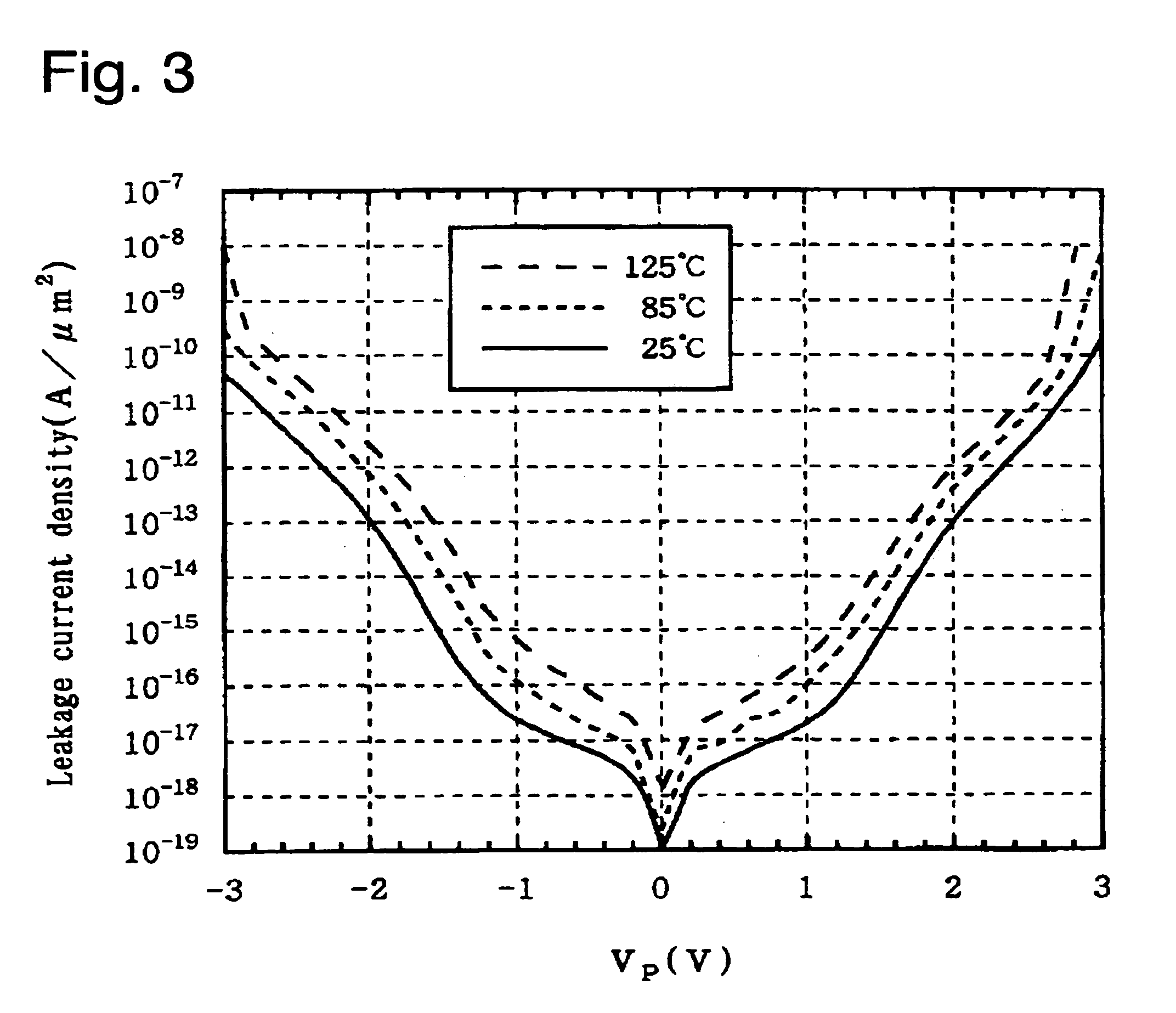

[0069] According to this second embodiment, in a thin film capacitor of a MIM structure having a capacitor dielectric film formed of at least one material selected from the group consisting of ZrO2, HfO2, (Zrx, Hf1-x)O2 (0y, Ti1-y)O2 (0z, Ti1-z)O2 (0k, Til, Hfm)O2 (0

[0070] The thin film capacitor of the MIM structure in accordance with the first embodiment having the capacitor dielectric film formed of at least one material selected from the group consisting of ZrO2, HfO2, (Zrx, Hf1-x)O2 (0y, Ti1-y)O2 (0z, Ti1-z)O2 (0k, Til, Hfm)O2 (02O5, and therefore, can be satisfactorily used as a memory capacitor in a DRAM cell. However, when the film thickness of the capacitor dielectric film is decreased, the capacitance increase is small (namely, the decrease of teq is small), and on the other hand, the lea...

third embodiment

[0085] Now, the present invention will be described.

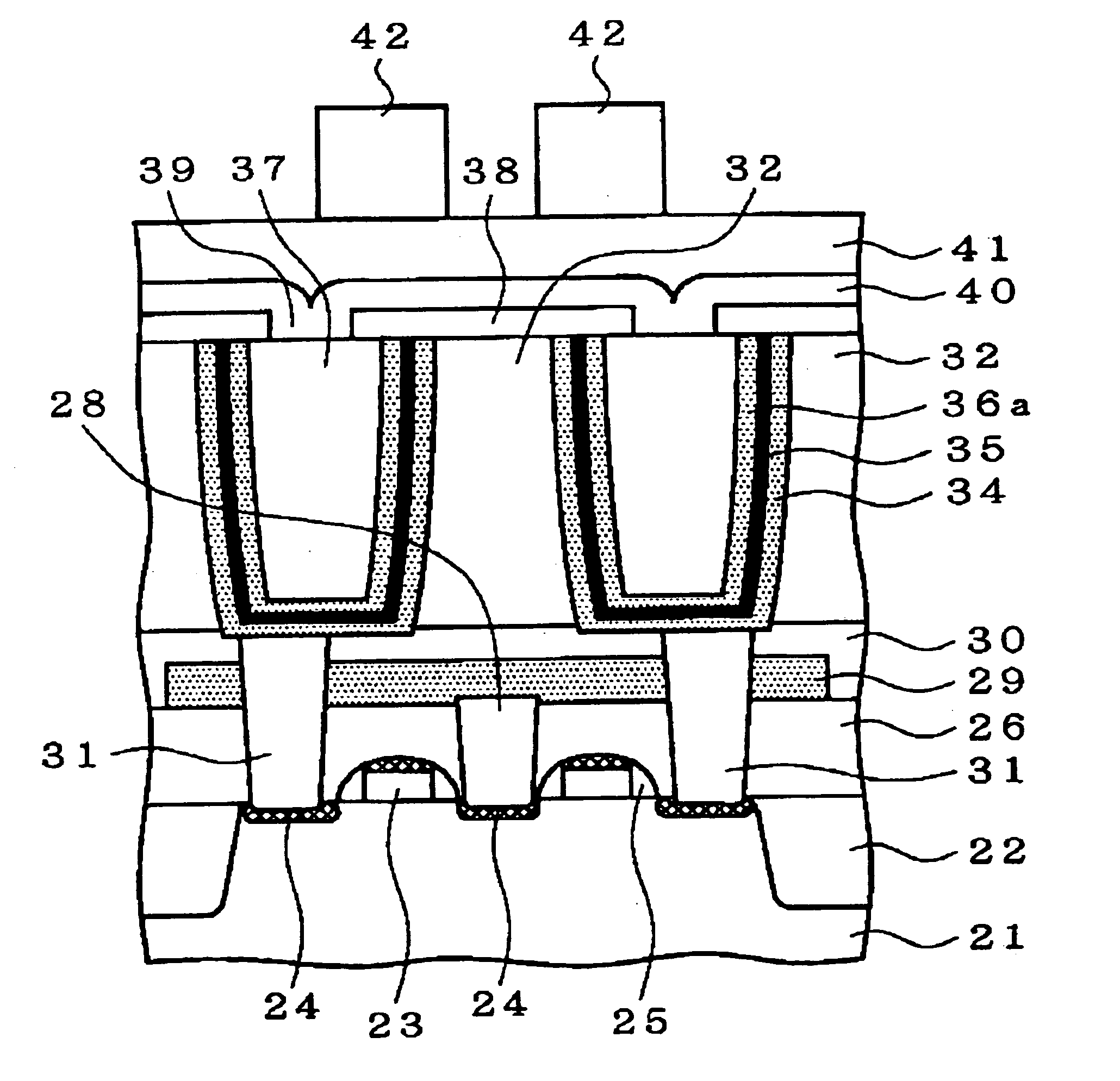

[0086] According to this third embodiment, in a stacked MIM (metal-insulator-metal) capacitor in a DRAM or a logic mixed DRAM having a logic section and a memory section formed on the same chip, a lower electrode, a capacitor dielectric film and an upper electrode are sequentially formed in the ALD process by use of an ALD apparatus.

[0087] First, a conventional method for forming the stacked MIM capacitor in a DRAM or a logic mixed DRAM will be described. As shown in FIG. 7, a transistor is formed, and after a capacitor contact 11 is formed, an interlayer insulator film 12 is deposited. Then, an opening is formed in the interlayer insulator film 12 by use of lithography, and a lower electrode (metal) 13 is deposited. Thereafter, a resist 14 is filled into the opening to protect the opening, and only an upper portion of the interlayer insulator film is removed by an etch-back process or a CMP (chemical mechanical polishing) process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nanoscale particle size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Dielectric polarization enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com