Electrolytic cell for removal of material from a solution

a technology of electrolysis cell and solution, which is applied in the direction of electrolysis organic production, electric furnace, furnace, etc., can solve the problem of inability to dislodge the material, achieve the effect of economic recovery of metals, avoid complex cleaning methods of conductive surfaces, and simplify separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

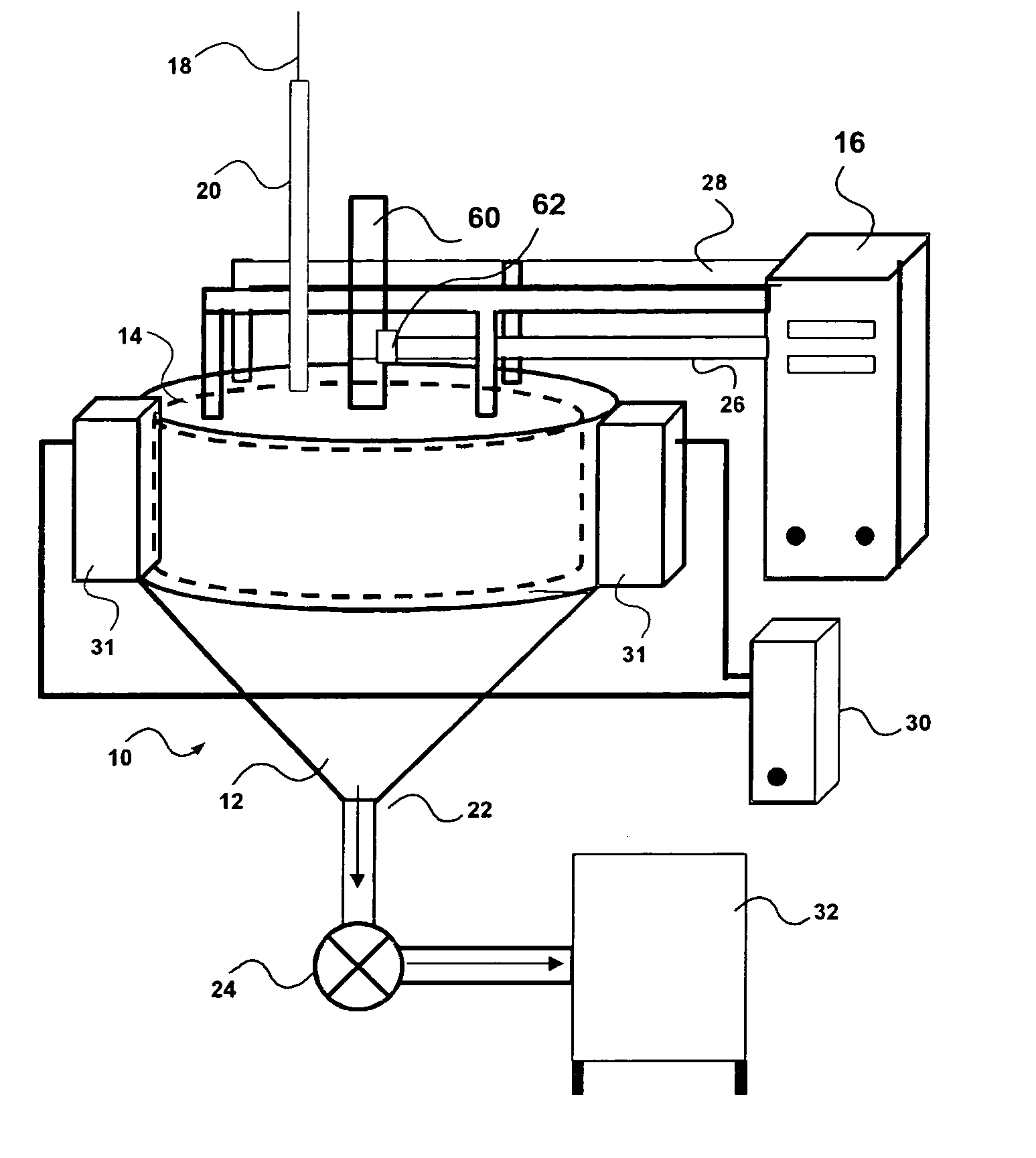

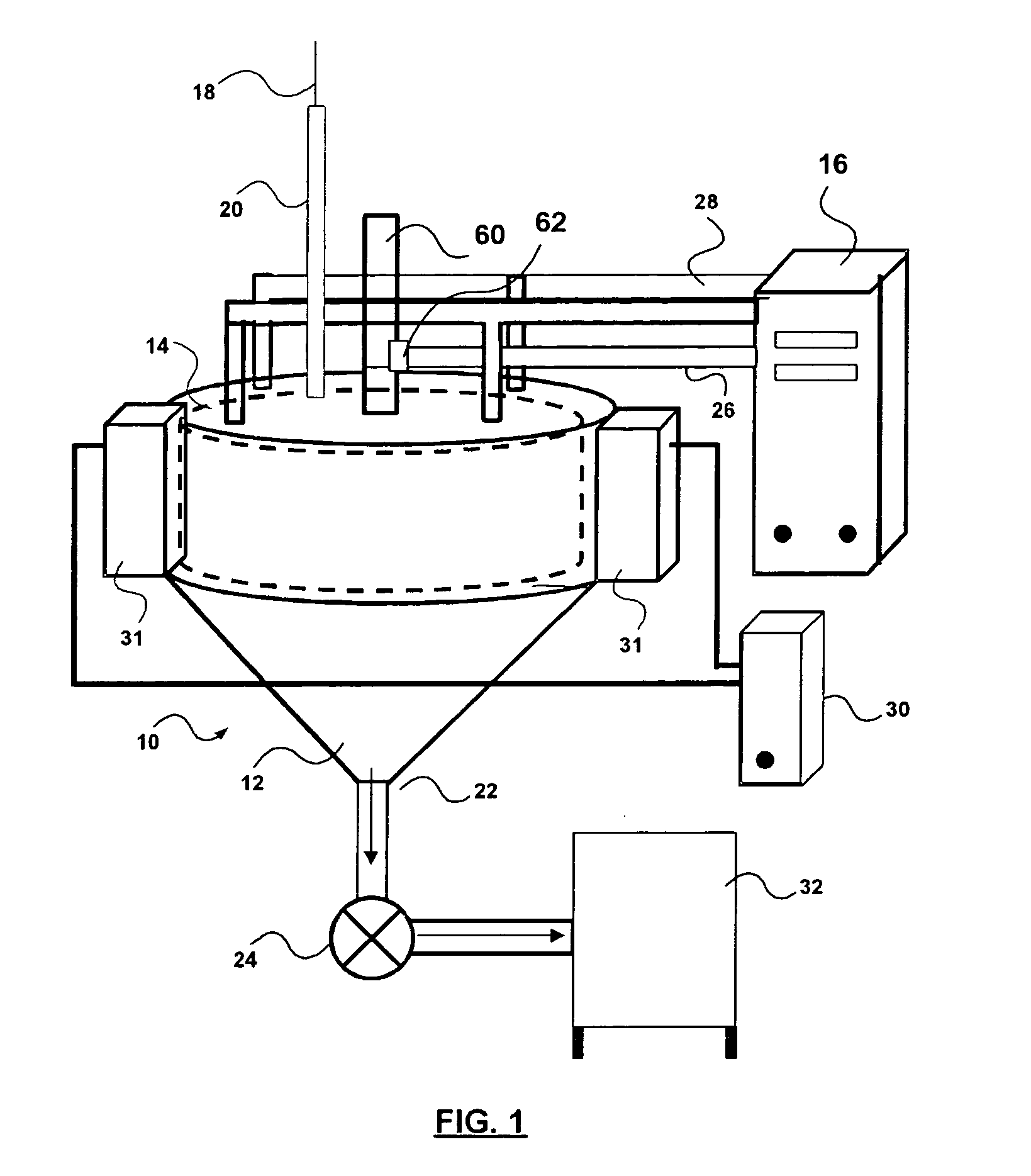

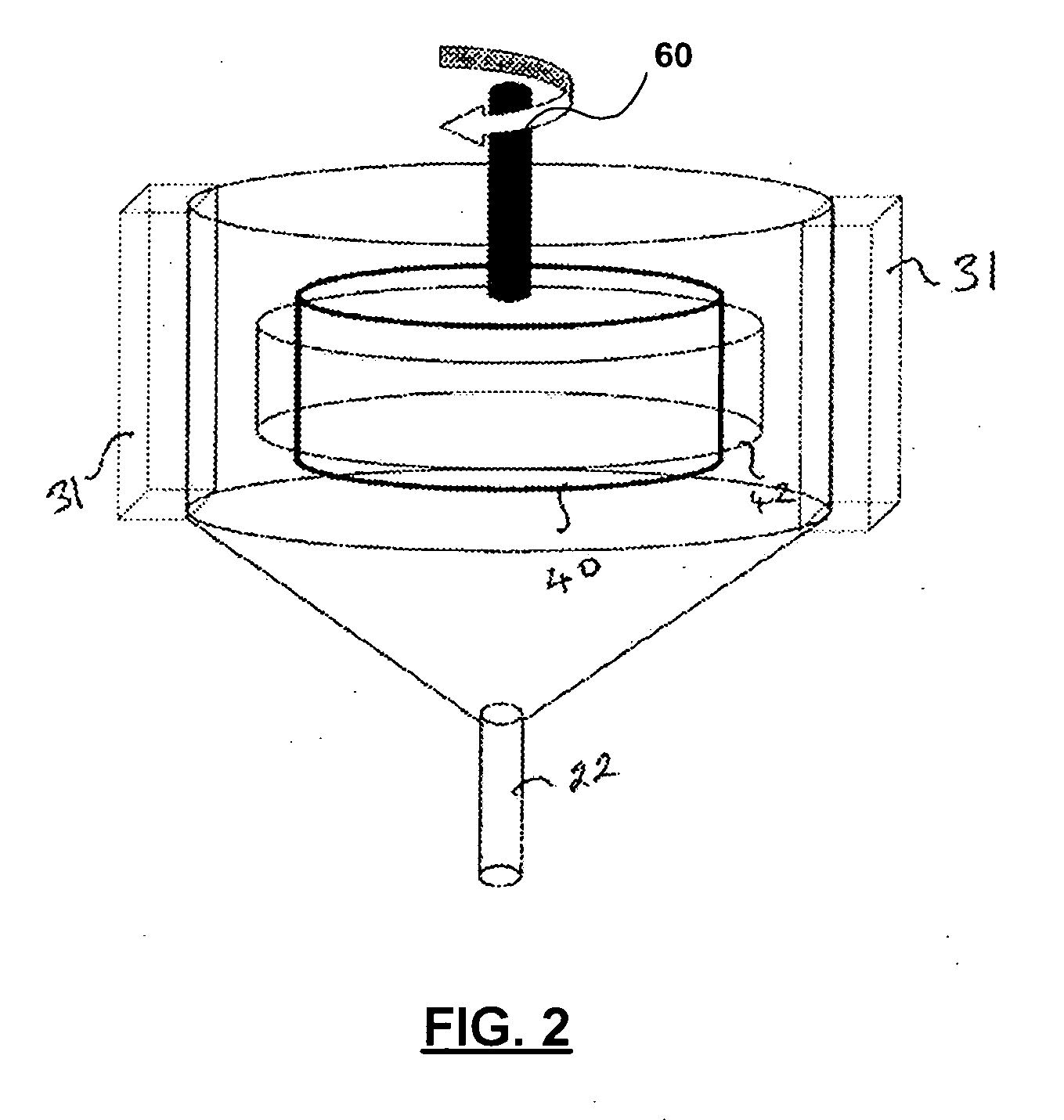

Image

Examples

example 1

[0060] A solution containing 100 ppm of zinc from a zinc chloride plating solution is reduced to 15 ppm in two steps: the first step uses a current density of 80 mA / cm2 at a rotatable electrode whose tangential speed is 3.5-4.5 m / sec with a treatment time 1.33 times the flow rate; and the second uses half the current density of the first step but twice the time of treatment.

example 2

[0061] A solution containing 200 ppm of copper from an acid copper plating solution is reduced to 20 ppm with a current density of 60 mA / cm2 at a rotatable electrode with a tangential speed of 3.0-4.0 m / sec with a treatment time equal to 1.25 times the flow rate.

example 3

[0062] A solution containing 200 ppm of nickel from an acid nickel sulfamate plating solution is reduced to 30 ppm with a current density of 27 mA / cm2 at a rotatable electrode with a tangential speed of 2.5-3.5 m / sec with a treatment time equal to 1.50 times the flow rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tangential speed | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com