Assembly of arrays on chips segmented from wafers

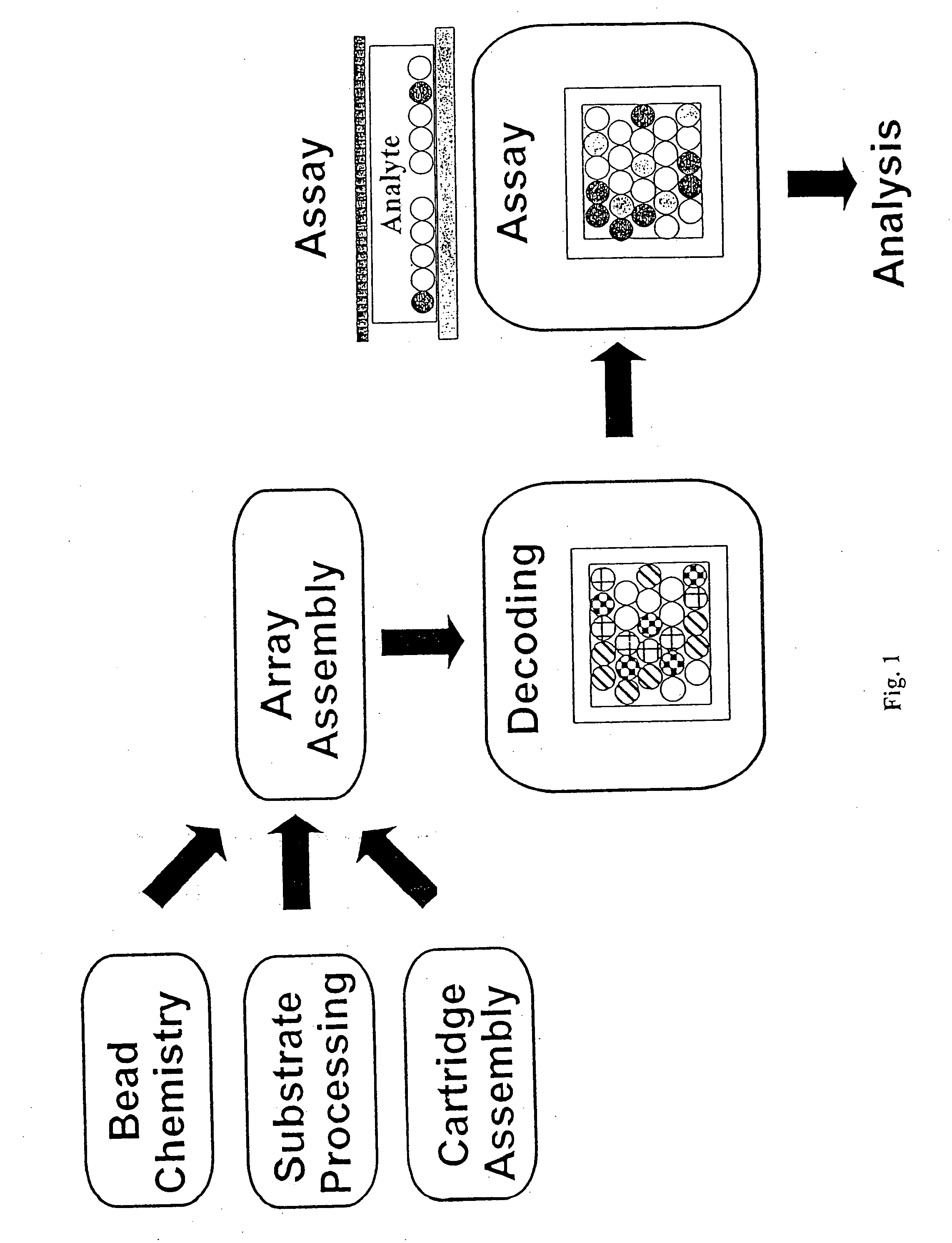

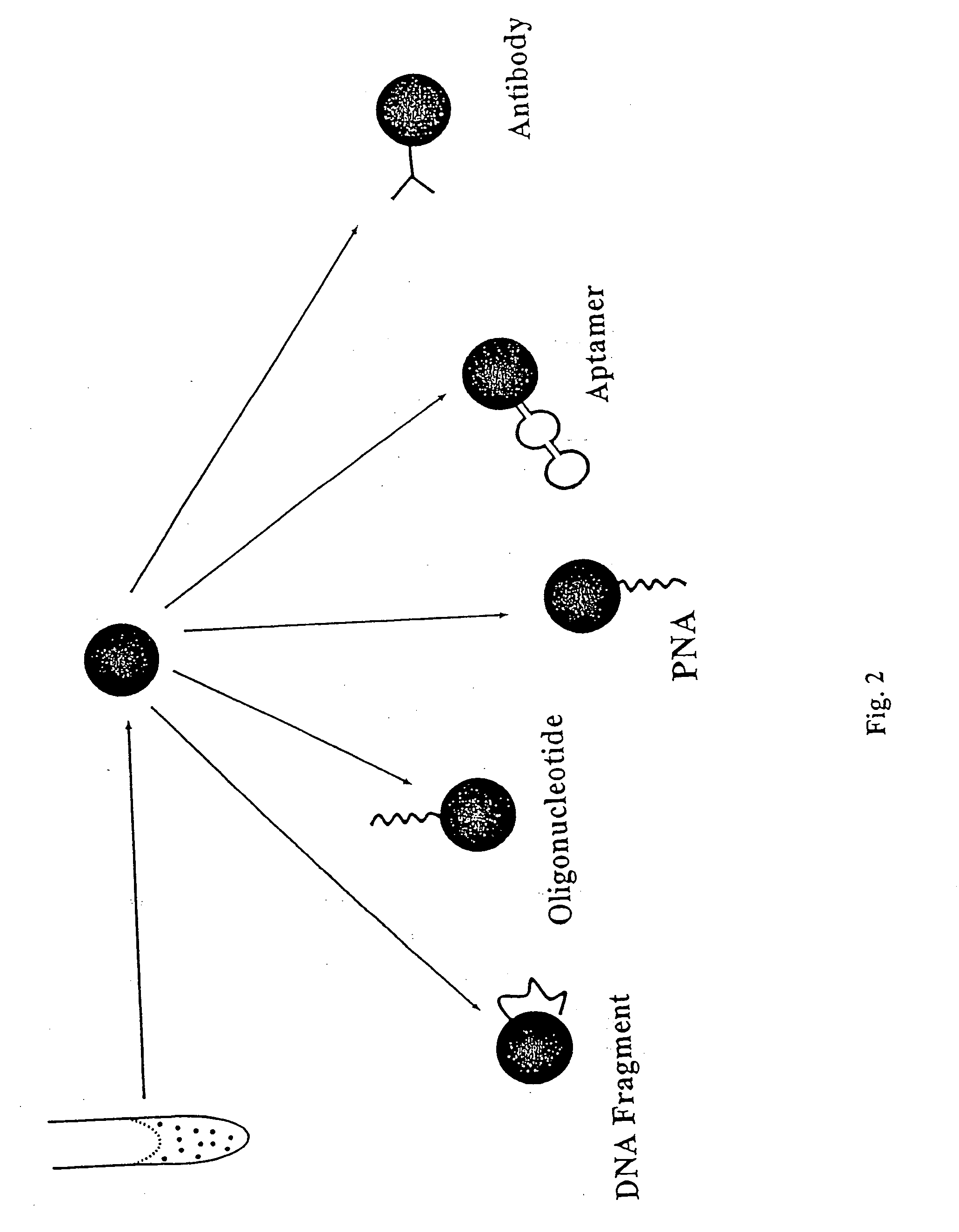

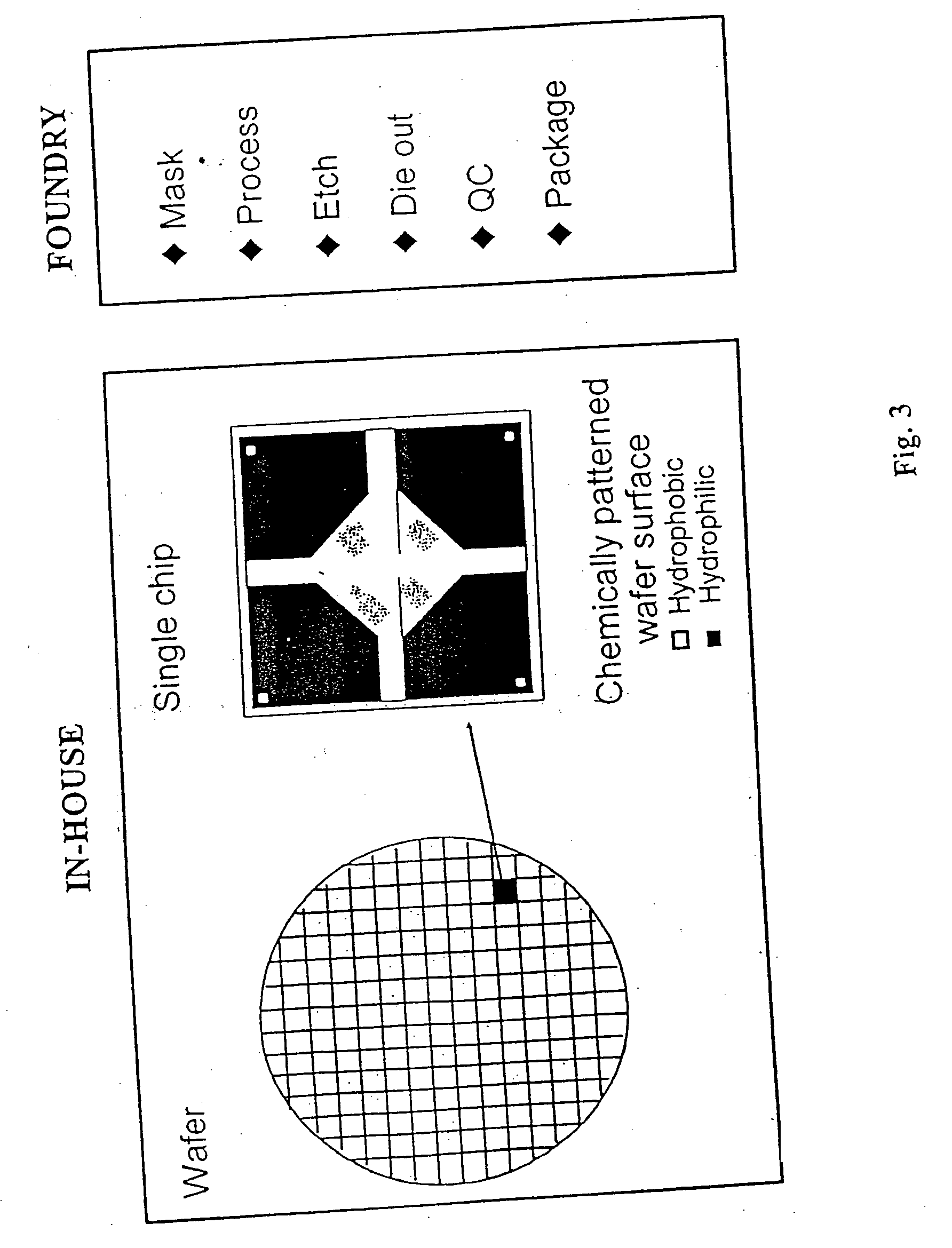

a technology of arrays and wafers, applied in the field of material science and analytical chemistry, can solve the problems of high parallel array format of analysis, sample processing and analysis by way, and has not been described to date, and none of the array formation techniques of the prior art permit the formation of arrays in real tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Optically Programmable Array Formation

[0124] As illustrated in FIG. 9, LEAPS serves to simultaneously assemble multiple random encoded subarrays and to “drag-and-drop” these subarrays into separate, but proximate locations on the chip within a common, enclosed liquid environment. Two sets of beads (2.8 μm Oligo-(dT)25, Dynal, Oslo, Norway), dispensed from separate reservoirs A and B, were simultaneously assembled into distinct subarrays within the same fluid; subarrays were then simultaneously placed into desired destinations as directed by spatially varying illumination profiles which were generated and projected onto the substrate by a PC-programmable illumination pattern generator (described in U.S. Ser. No. 09 / 397,793, filed Sep. 17, 1999, which is incorporated herein by reference in its entirety). This drag-and-drop operation reduced the separation between the two sub-arrays from approximately 250 μm to 20 μm. Beads were moved at 5 V at a frequency of 2 kHz; total power projec...

example 2

Array Formation on Patterned Surface

[0125] Illustrated in FIG. 10 is an array of encoded beads assembled on a patterned silicon chip using an AC voltage of 1-2 V and a frequency of 100-150 Hz, applied across a 100 μm electrode gap filled with an aqueous bead suspension; a thermal oxide (˜1000 Å) on the substrate was patterned by etching the oxide to a thickness of 50-100 Å in a set of square features (˜30×30 μm2) on 130 μm centers; arrays of similar layout also can be produced in response to suitable illumination patterns. Each sub-array shown here contains approximately 80 beads coupled with anti-cytokine monoclonal antibodies. Carboxylate-modified polystyrene beads of 5.5 μm diameter (Bangs Laboratory, Fishers, Ind.) were stained with a combination of two types of fluorescent dyes and were then functionalized with anti-cytokine-mAb. The assembly process ensures collection of all beads at the substrate surface. Bead encoding was as follows: IL-2 (Bright Red); IL-4 (Dim Red); IL-6 ...

example 3

Formation of Arrays of Magnetic Nanoparticles

[0126] Colloidal particles exhibiting a finite diamagnetic susceptibility, when disposed on a planar substrate can be assembled into ordered arrays in response to increasing magnetic fields. Commercially available superparamagnetic particles (Dynal, Oslo, NO), dispersed from a fluid suspension onto the planar surface of the lower of two parallel bounding surfaces of a fluid cell (“sandwich” geometry), when exposed to a homogeneous axial magnetic field (oriented normal to the substrate plane), will form ordered assemblies. As a function of increasing magnetic field strength, and for given diamagnetic susceptibility of the particles as controlled by the manufacturing process known to the art, ordered planar assemblies and linear strings of beads oriented normal to the substrate can be formed. Permanent magnets can be designed so as to produce the field strength required to realize the desired configuration of the assembly. Requisite magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transparency | aaaaa | aaaaa |

| Electric impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com