Method and apparatus for microcellular polymer extrusion

a microcellular polymer and extrusion method technology, applied in the field of polymer foam processing, can solve the problems of non-uniform distribution of cells in the material, low number of voids or cells per unit volume of material, and inability to achieve thin sheets and sheets with very smooth finishes. to achieve the effect of constant pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0162] The following example describes a process for determining the critical dimensions of a die of this invention, using an approximation analysis. This example will enable those skilled in the art to develop alternative die designs that can be used to make microcellular plastics, yet still fall within the spirit and scope of the presently claimed invention.

[0163] If it is assumed that the plastic will expand uniformly in all three directions, then the ratio of the density of the microcellular plastic ρf to the density of the unfoamed plastic ρ0 may be written, as a first approximation, as:

ρƒ / ρ0=(1 / a)3 (6)

where a is the linear expansion ratio during foaming. Equation 6 states that if one wishes to decrease the density by a factor of two, the linear expansion ratio must be about 1.26.

[0164] If the die consists of a large number of circular holes through which the plastic is extruded, the area ratio of the holes to the total final area of the extrudate determines the final den...

example 2

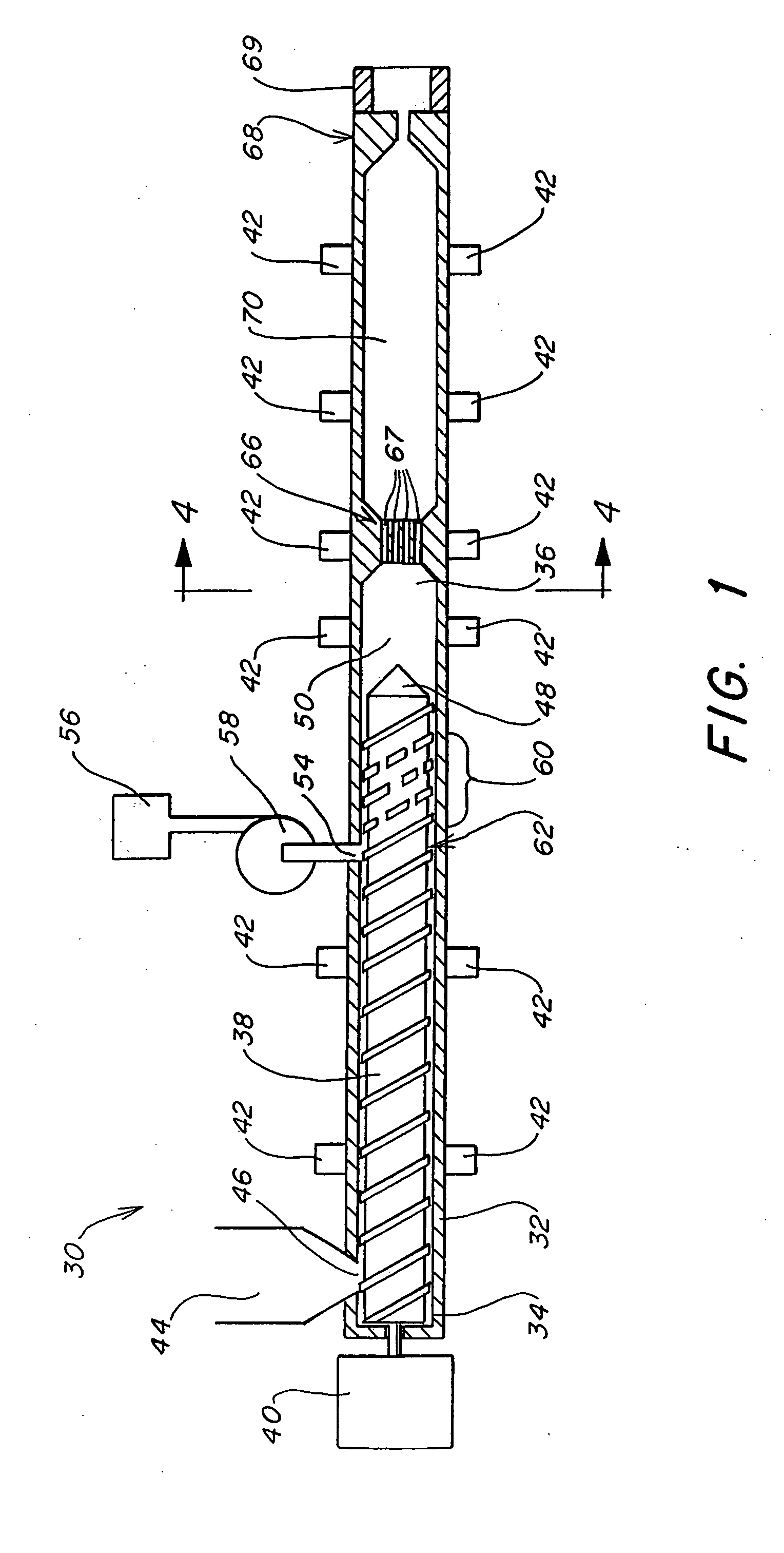

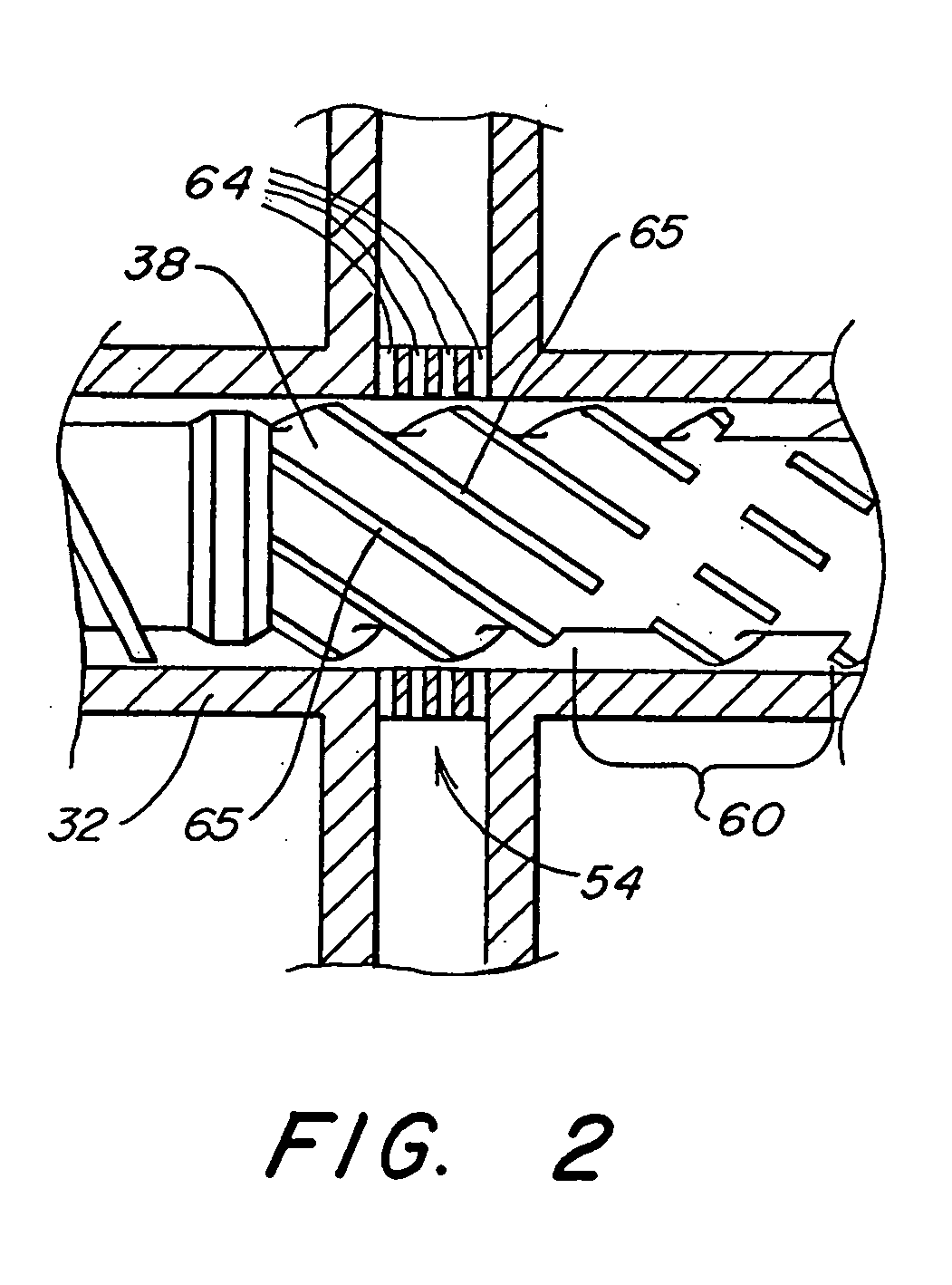

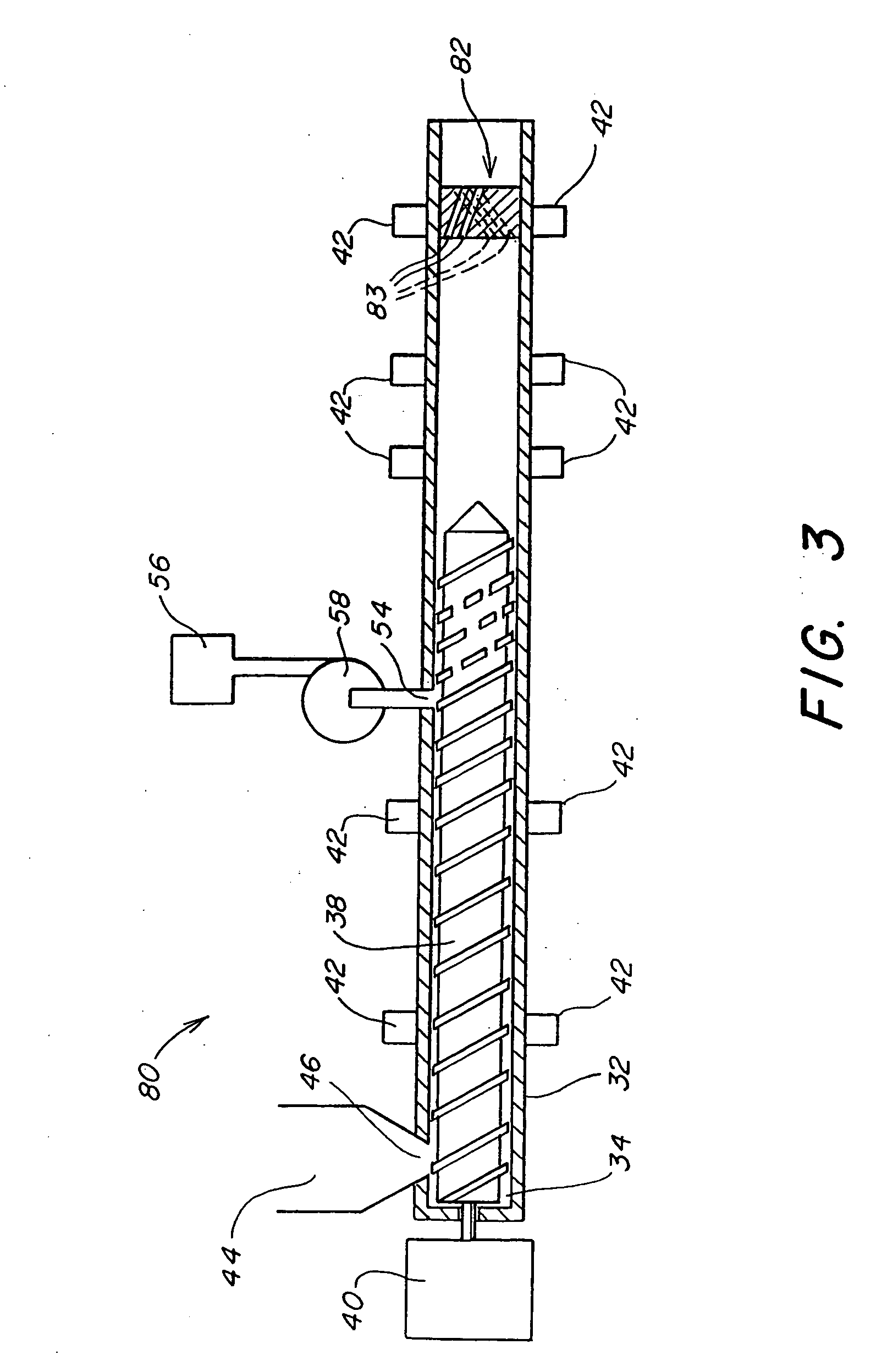

Tandem Wire Extrusion System for Microcellular Material

[0166] A tandem extrusion line (Akron Extruders, Canal Fulton, Ohio) was arranged including a 2 inch, 32 / 1 L / D primary extruder and a 2.5 inch, 34 / 1 L / D secondary extruder. An injection system for injection of CO2 into the primary was placed at a distance of approximately 20 diameters from the feed section. The injection system included 4 equally-spaced circumferentially, radially-positioned ports, each port including 176 orifices, each orifice of 0.02 inch diameter, for a total of 704 orifices.

[0167] The primary extruder was equipped with a two-stage screw including conventional first-stage feed, transition, and metering sections, followed by a multi-flighted (four flights) mixing section for blowing agent dispersion. The screw was designed for high-pressure injection of blowing agent with minimized pressure drop between the first-stage metering section and point of blowing agent injection. The mixing section included 4 fligh...

example 3

Extrusion of Microcellular, Flame-Retardant High-Density Polyethylene onto 24 AWG Solid Copper Wire

[0173] Polyethylene pellets (Union Carbide UNIGARD-HP™ DGDA-1412 Natural, 1.14 g / cc) were gravity-fed from the hopper of the primary screw into the extrusion system of Example 2. Primary screw speed was 15 RPM giving a total output (bleed and die) of approximately 15 lbs / hr of microcellular material. Secondary screw speed was 3 RPM. Barrel temperatures of the secondary extruder were set to maintain a melt temperature of 336° F. measured at the end of the secondary extruder. CO2 blowing agent was injected at a rate of 0.54 lbs / hr resulting in 3.6 wt % blowing agent in the melt. Pressure profile between the injection ports and the inlet of the crosshead was maintained between 3400 and 4040 psi. Approximately 1.2 lbs / hr fluid microcellular material precursor flowed through the crosshead, which could be controlled by adjustment of the bleed valve.

[0174]FIGS. 15 and 16 are photocopies of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com