Color organic EL display and method for manufacturing the same

a technology of organic el and display, applied in the direction of discharge tube luminescnet screen, discharge tube/lamp details, incadescent envelope/vessel, etc., can solve the problems of deterioration of gas barrier characteristics, low production efficiency, and poor productivity, so as to improve the step coverage of the gas barrier layer, the effect of improving the coating performance and reducing the number of pin holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

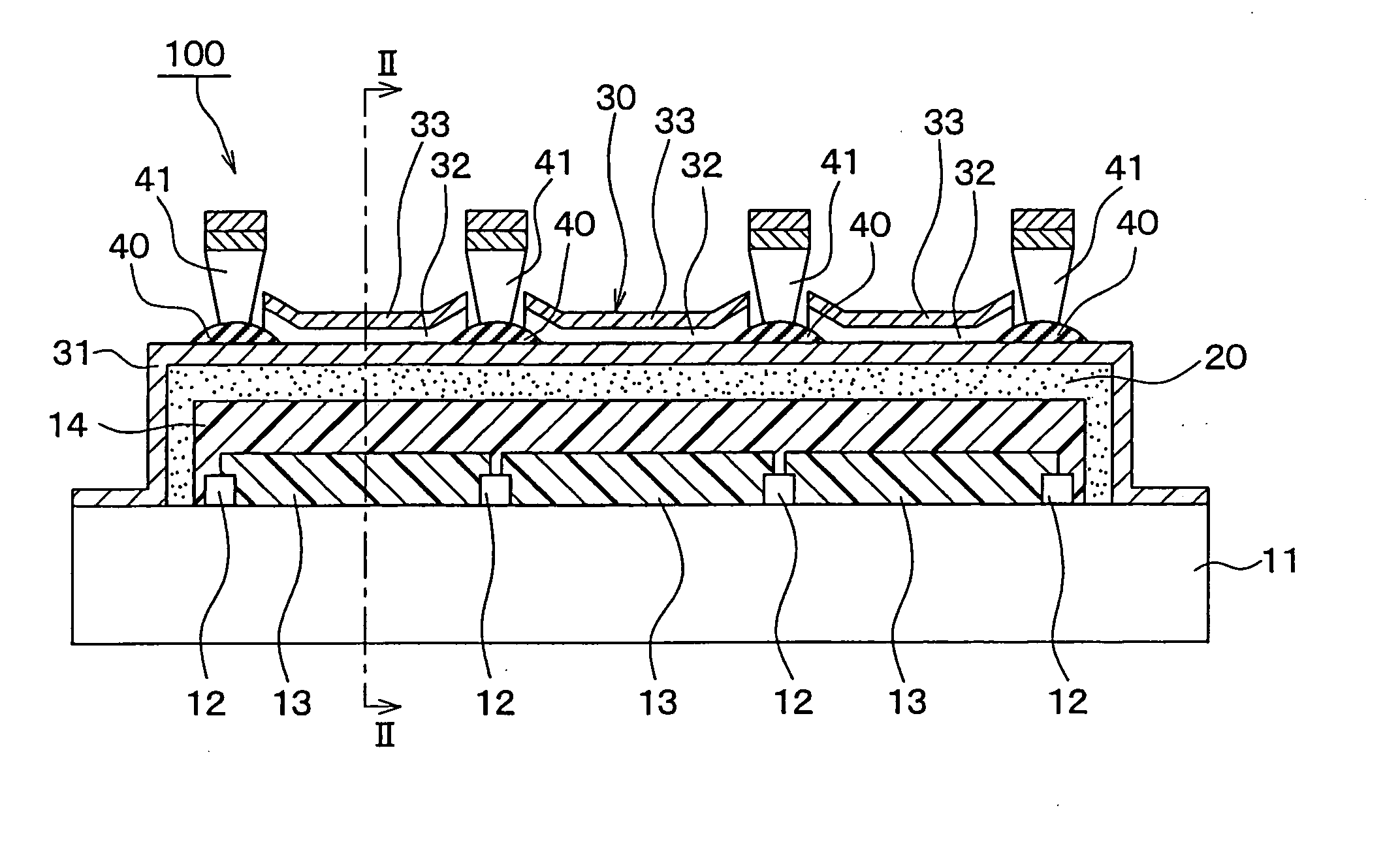

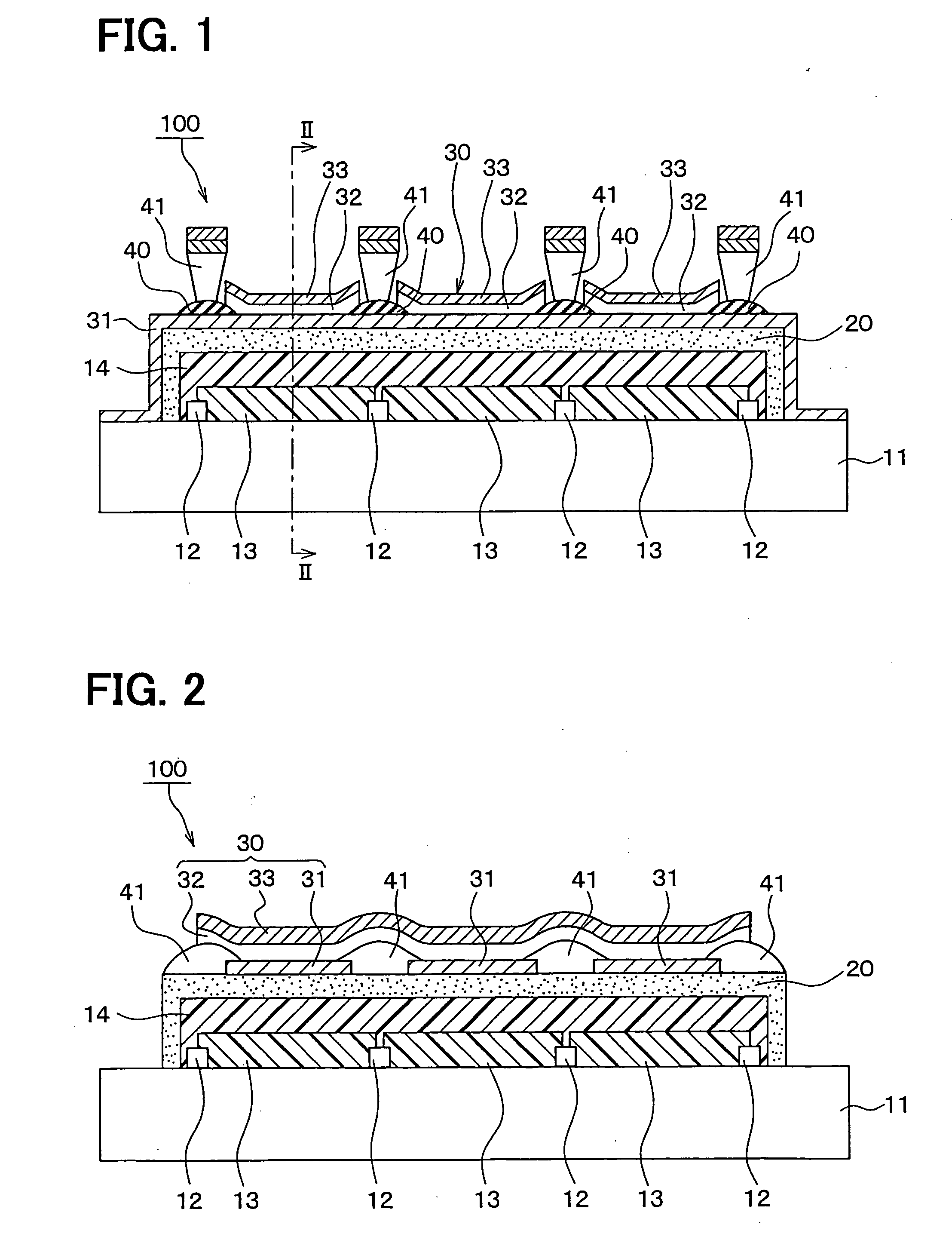

[0045]FIG. 1 is a diagram for indicating a substantially sectional structure of a color organic EL display 100 according to a first embodiment mode of the present invention. FIG. 2 is a diagram for showing a substantially sectional structure of the color organic EL display 100, taken along a dot and dash line II-II shown in FIG. 1.

[0046] [Structure]

[0047] A substrate 11 is made of a glass substrate, a substrate made of a resin (resin substrate), or the like. In this color organic EL display 100 of the first embodiment mode, the substrate 11 corresponds to a transparent substrate 11 which is made of a glass substrate.

[0048] Red, blue, and green color filter layers 13 which correspond to three primary colors of light have been provided on one plane of this glass substrate 11. It should be noted that shadow masks (black matrix) 12 used to separate the color filter layers 13 have been formed on one plane of the substrate 11, and the color filter layers 13 have been provided with the s...

second embodiment

[0159]FIG. 4 is a diagram for indicating a substantially sectional structure of a color organic EL display 200 according to a second embodiment mode of the present invention.

[0160] In this color organic EL display 200, in such a case that the anode 31 has been formed on the gas barrier layer 20 and functions as a transparent conducting film which constitutes the organic EL structural body 30, it is preferable that an SiO2 layer 50 capable of improving a close contacting characteristic between these gas barrier layer 20 and transparent conducting film 31 is interposed between the gas barrier layer 20 and the transparent conducting film 31.

[0161] This SiO2 layer 50 may be formed by performing a sputtering method, or the like, and a film thickness thereof may be selected to be, for example, approximately 20 nm. Since the close contacting characteristic between the gas barrier layer 20 and the transparent conducting film 31 can be improved by this SiO2 layer 50, there is a merit that ...

third embodiment

[0162]FIG. 5 is a diagram for indicating a substantially sectional structure of a color organic EL display 300 functioning as an organic electronic device element according to a third embodiment mode of the present invention.

[0163] Also, the substrate 11 is constituted by a glass substrate, a substrate made of a resin (namely, resin substrate), or the like. The substrate 11 corresponds to such a transparent substrate 11 which is made of non-alkali glass and does not contain such an alkaline component as potassium and sodium.

[0164] Similar to the above-explained embodiment mode, the shadow mask (black matrix) 12 and the color filter layers 13 have been formed on one plane of this substrate 11, on which the transparent overcoat layer 14 has been formed as a fattening layer.

[0165] Then, the gas barrier layer 20 has been formed on the overcoat layer 14 in such a manner that this gas barrier layer 20 covers the overcoat layer 14 by executing an atomic layer growing method at a tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com