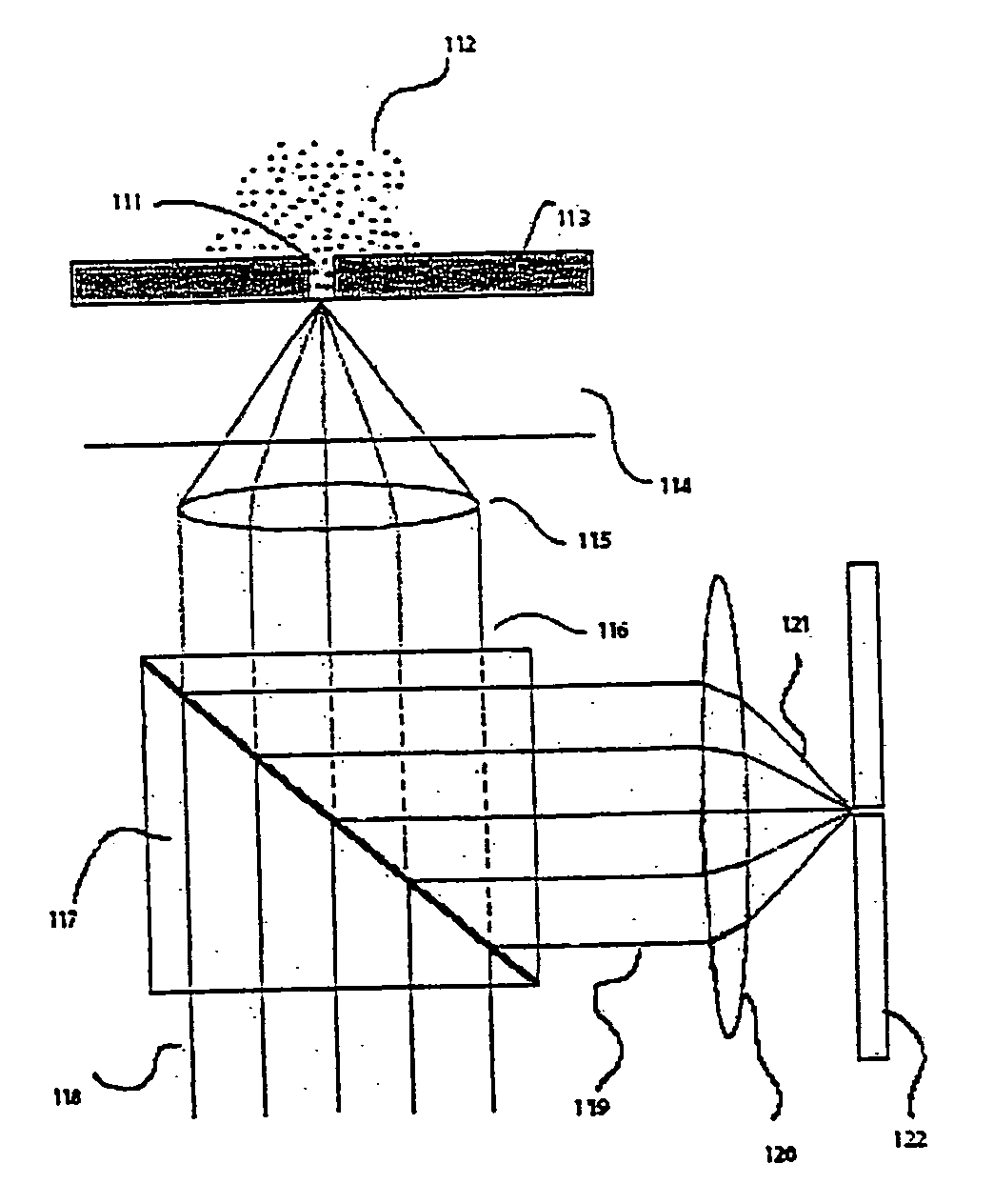

Fabrication of optical confinements

a technology of optical confinement and fabrication method, which is applied in the direction of cladding optical fibre, laboratory glassware, instruments, etc., to achieve the effect of illuminating optical confinement and high fill fraction array

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0204] The following provides an illustrative process of fabricating zero-mode waveguide. The parameters described herein are meant to be illustrative and not intended to be limiting in any manner. [0205] 1. Substrates: Substrates are double polished, 60 / 40 scratch / dig surface quality, Fused Silica wafers, cut to 100 millimeters(+ / −0.2 mm) diameter, and 175 micrometer(+ / −25 micrometers) thick and a total thickness variation of less than 25 micrometers. [0206] 2. Clean: A mix of 5 parts deionized water, 1 part of (30% v / v Hydrogen Peroxide in water), 1 part of (30% v / v Ammonium Hydroxide in water) is heated to 75 degree Celsius on a hotplate. The wafers are immersed in the mix using a Teflon holder or other chemically resistant holder for a duration of 15 minutes. [0207] 3. Rinsing: The holder containing the wafers is removed from the RCA clean bath and immersed in a bath of deionized water. The wafers are left in this second bath for a 2 minutes period. The holder still containing t...

example 2

Monitoring Enzymatic Synthesis of a DNA Strand by a Single DNA Polymerase Molecule in Real Time

[0236] This experiment can be performed using the optical system and reaction mixtures detailed below. However, the reference to any particular optical system and parameter, buffer, reagent, concentration, pH, temperature, or the like, is not intended to be limiting. They are included to provide as one illustrative example of carrying out the methods of the present invention.

[0237] Enzymatic synthesis of a DNA strand by a single DNA polymerase molecule was tracked in real time using a fluorescently labeled nucleotides. Individual Phi29N62D DNA polymerase enzymes (Amersham Biosciences, Piscataway, NJ) were immobilized in zero-mode waveguides (ZMWs) by non-specific binding using a dilute enzyme solution. After immobilization, the ZMW structures were washed to remove unbound enzyme, and then exposed to a solution containing the reaction reagents. As of the DNA template, a 70-bp pre-primed ...

example 3

Real Time Sequencing Using Multiple Different Labeled Nucleotides

[0243] An experiment similar to that described in Example 2, above, was performed using two different labeled nucleotide analogs. The experiment can be performed using the optical setup or system and reaction mixtures detailed as follows. However, the reference to any particular optical setup and parameter, buffer, reagent, concentration, pH, temperature, or the like, is not intended to be limiting. They are included to provide as one illustrative example of carrying out the methods of the present invention.

[0244] Preparing reaction samples: Approximately 10 μl of reaction mixture is used in one sequencing reaction. The reaction mixture generally contains 0.5-1 mM MnCl2, 0.1-1 uM DNA template, 10 μM dATP, 10 μM dGTP, 10 μM SAP-treated Alexa 488-dC4P, and 10 μM SAP-treated Alexa 568-dT4P, and DNA polymerase. The labeled dC4P and dT4P can also be substituted with labeled dA4P and dG4P.

[0245] Preparing Zero-mode waveg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com