Storage battery system and automobile

a storage battery and battery technology, applied in the field of storage batteries, can solve the problems of battery incurring very large thermal deterioration, battery swelling, and unsolved problems, and achieve the effect of suppressing battery swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

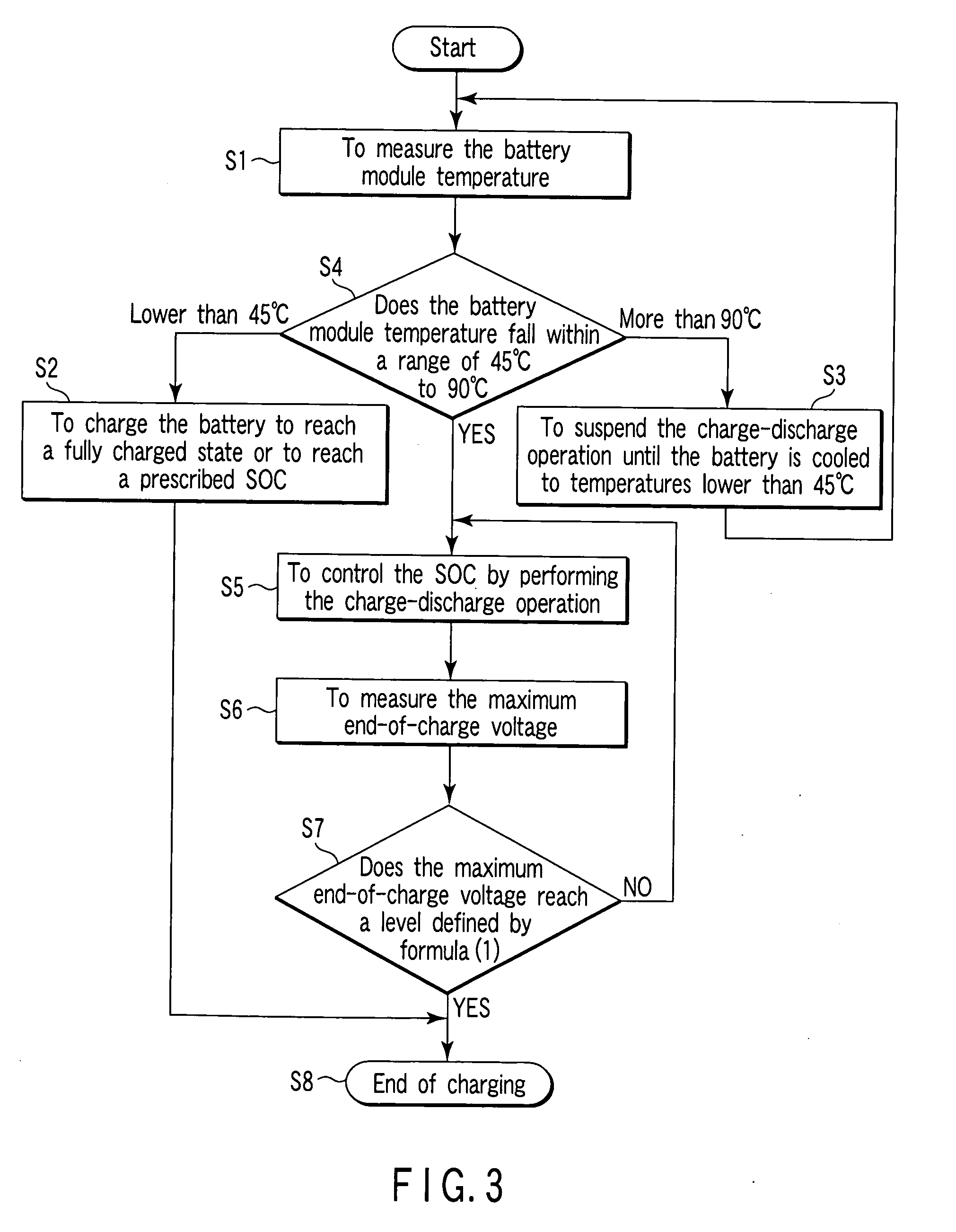

[0036] The present inventors have continued further research with attention paid to the situation that the battery module is swollen if the charging depth is increased under high temperatures in applying regenerative charging to the battery module of a nonaqueous electrolyte secondary battery comprising a negative electrode including a lithium-titanium composite oxide as the negative electrode active material. The present inventors find that the reducing decomposition potential of the nonaqueous solvent contained in the nonaqueous electrolyte is shifted toward the nobler side simultaneously with the shifting of the lithium absorbing potential of the lithium-titanium composite oxide toward the baser side. As a result, the potential difference between the reducing decomposition potential and the lithium absorbing potential is made small. It has been found that the potential difference that has been made small causes the reaction between the nonaqueous solvent and the lithium-titanium ...

second embodiment

[0117] The storage battery system according to the first embodiment of the present invention can be suitably used not only in the case of charging the battery by the regenerative power but also in the case of rapidly charging the battery under a high temperature environment no lower than 45° C. The particular situation of the rapid charging under a high temperature environment includes, for example, a power supply device for a digital camera, a power supply device for a lightweight vehicle such as an assist bicycle, a back-up power supply device for a personal computer and a factory (UPS: Uninterruptible Power Supply device), and a cleaning machine.

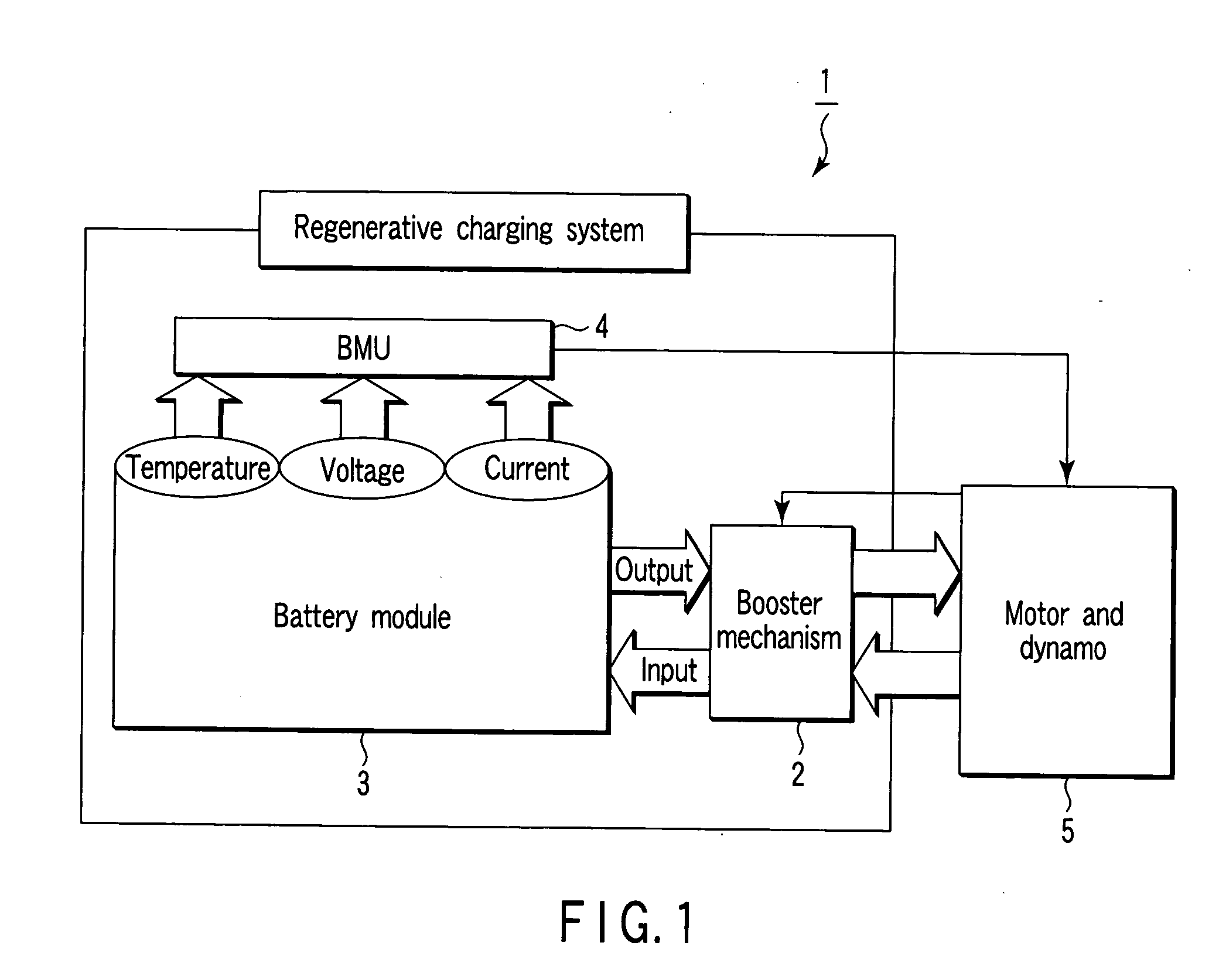

[0118] It is possible for the storage battery system according to the second embodiment of the present invention to be substantially equal to the storage battery system according to the first embodiment of the present invention described above, except that a regenerative power is not used for charging the storage battery according to the...

example 1

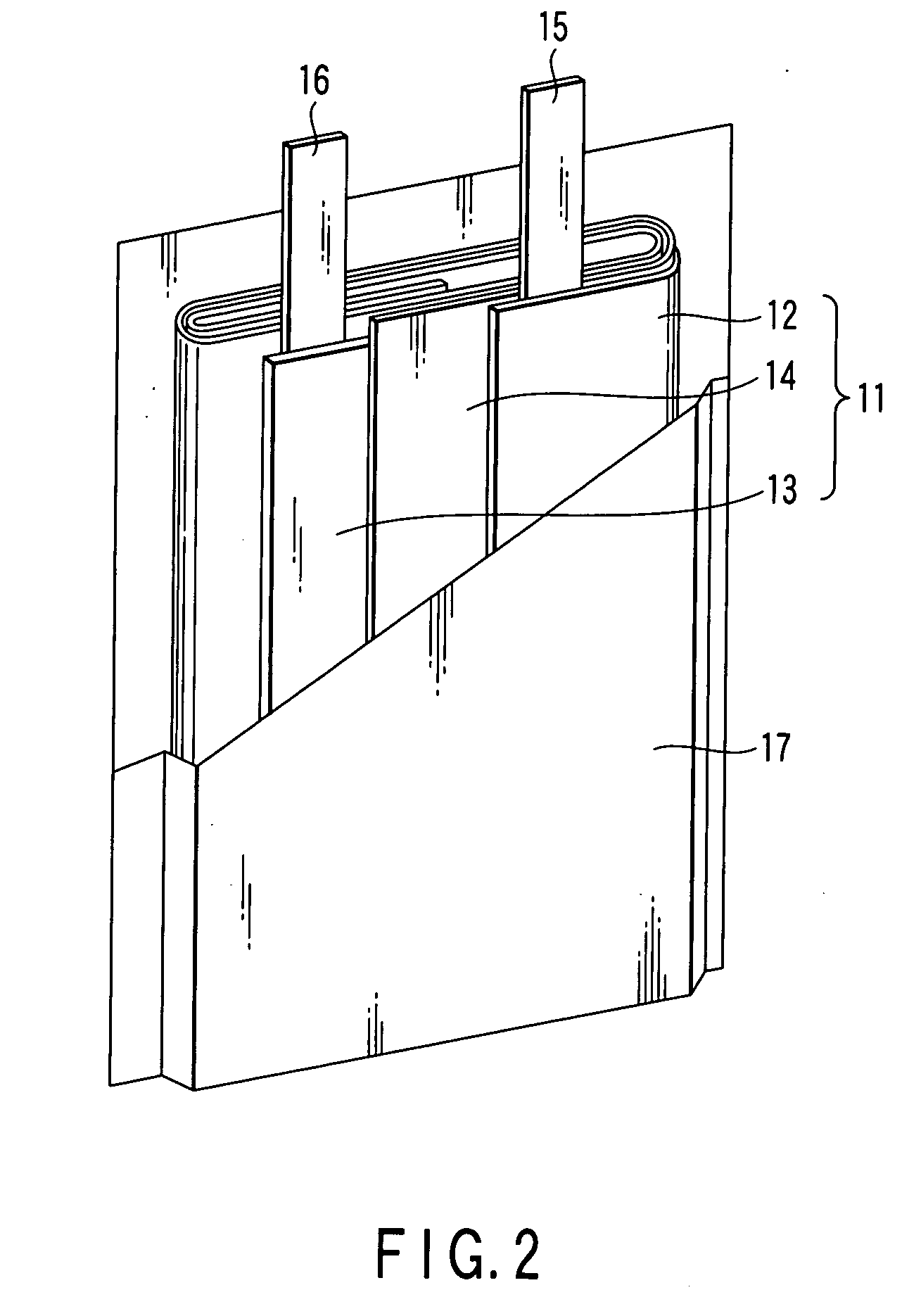

[0136] The manufacturing method of the negative electrode will now be described first. Specifically, a slurry was prepared first by dispersing lithium titanate (Li4Ti5O12) used as a negative electrode active material and having an average particle diameter of 0.3 μm, a carbon powder used as an electrically conductive agent and having an average particle diameter of 0.4 μm, and polyvinylidene fluoride (PVdF) used as a binder, which were mixed in a weight ratio of 90:7:3, in a n-methyl pyrrolidone (NMP) solvent, followed by coating an aluminum alloy foil (purity of 99.4%) having a thickness of 12 μm and an average crystal grain size of 50 μm with the resultant slurry and subsequently drying and pressing the aluminum alloy foil coated with the slurry so as to manufacture a negative electrode having an electrode density of 2.4 g / cm3. Incidentally, the negative electrode current collector was manufactured by annealing at 200° C. an aluminum alloy foil (purity of 99.4%) having a thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com