Method for production and upgrading of oil

a technology of oil and oil sand, applied in the direction of hydrogen separation using liquid contact, sustainable manufacturing/processing, and well accessories, etc., can solve the problems of limited use of heavy oil (density20°, viscosity>100 cp), and extra heavy oil/bitumen (density10°, viscosity>100000 cp) to achieve the effect of maximising synergetic effects and increasing recovery and transportation of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Generation of Hydrogen by Steam Reforming of Natural Gas

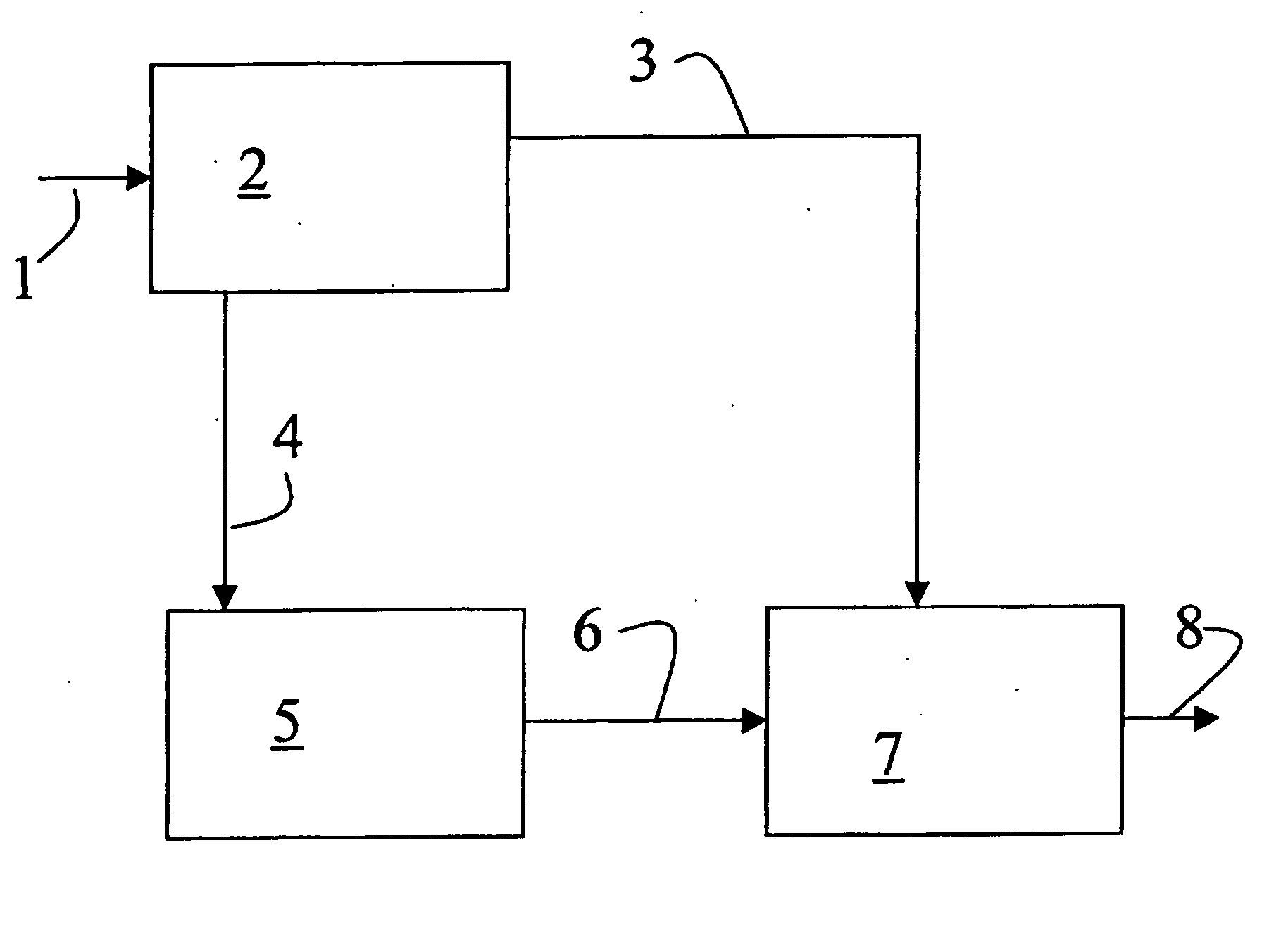

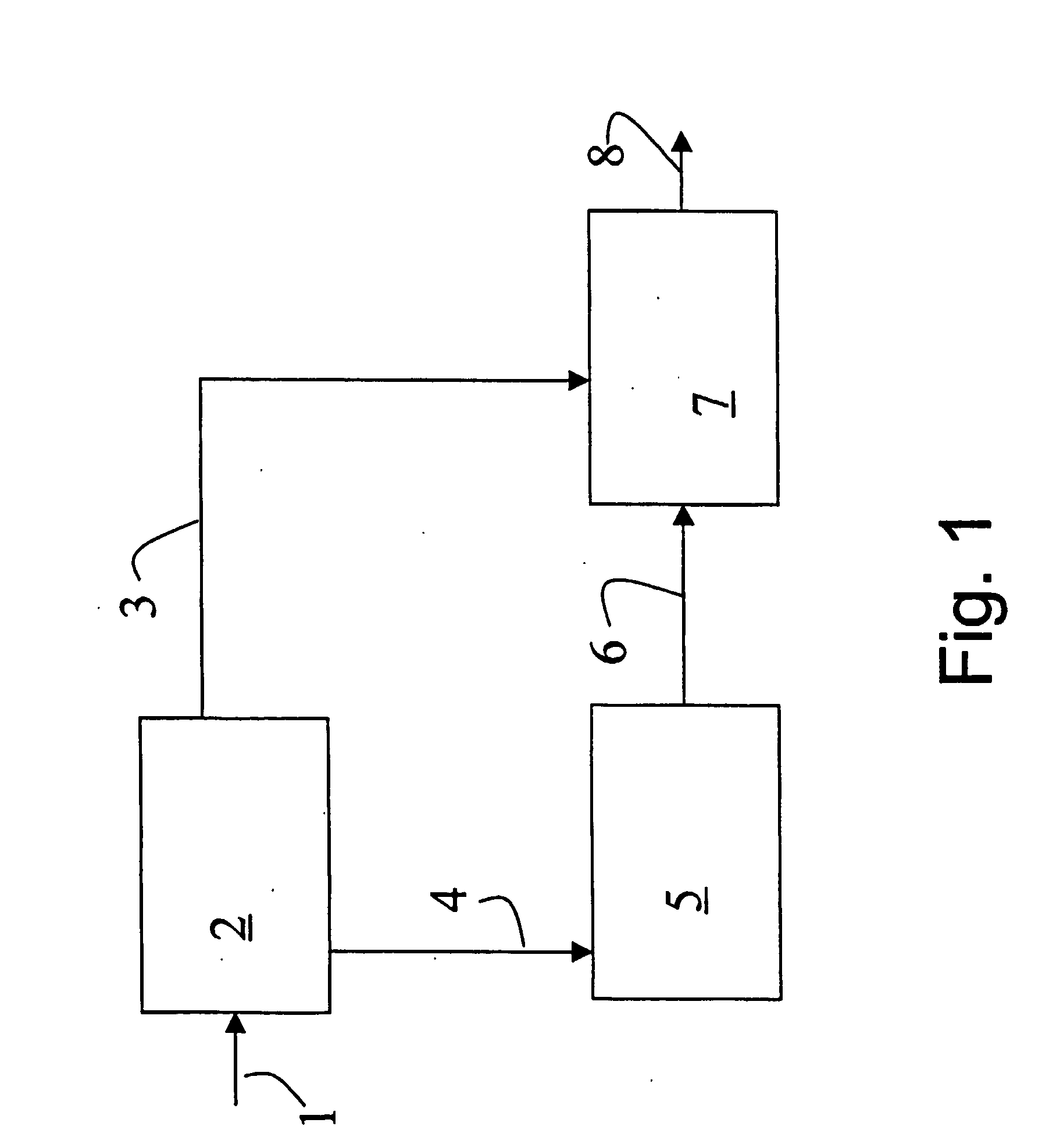

[0040]FIG. 1 is a simplified flow diagram of a plant according to a first preferred embodiment and is based on the production of 200 000 barrels per day of Zuata Heavy (API=9) oil.

[0041] Natural gas, 115 ton per hour, is introduced into a steam reforming unit 2 via a gas line 1. Steam reforming is an endothermal reaction. The steam reforming unit comprises a conventional steam generation unit where water is heated and converted into hot steam by combustion of any suitable fuel such as natural gas, lower or higher hydrocarbons.

[0042] The natural gas from the gas line 1 and the hot steam is reacted in one or more reactors according to the following reactions:

Steam reforming CH4+H2O═CO+3H2

Water gas shift CO+H2O═CO2+H2

[0043] The product gas from the steam reformer is then sent to a shift converter (one or two step) in which CO is converted to CO2 by the water gas shift reaction, and hydrogen is then separated by means of well...

example 2

Generation of Hydrogen by Autothermal Reforming of Natural Gas

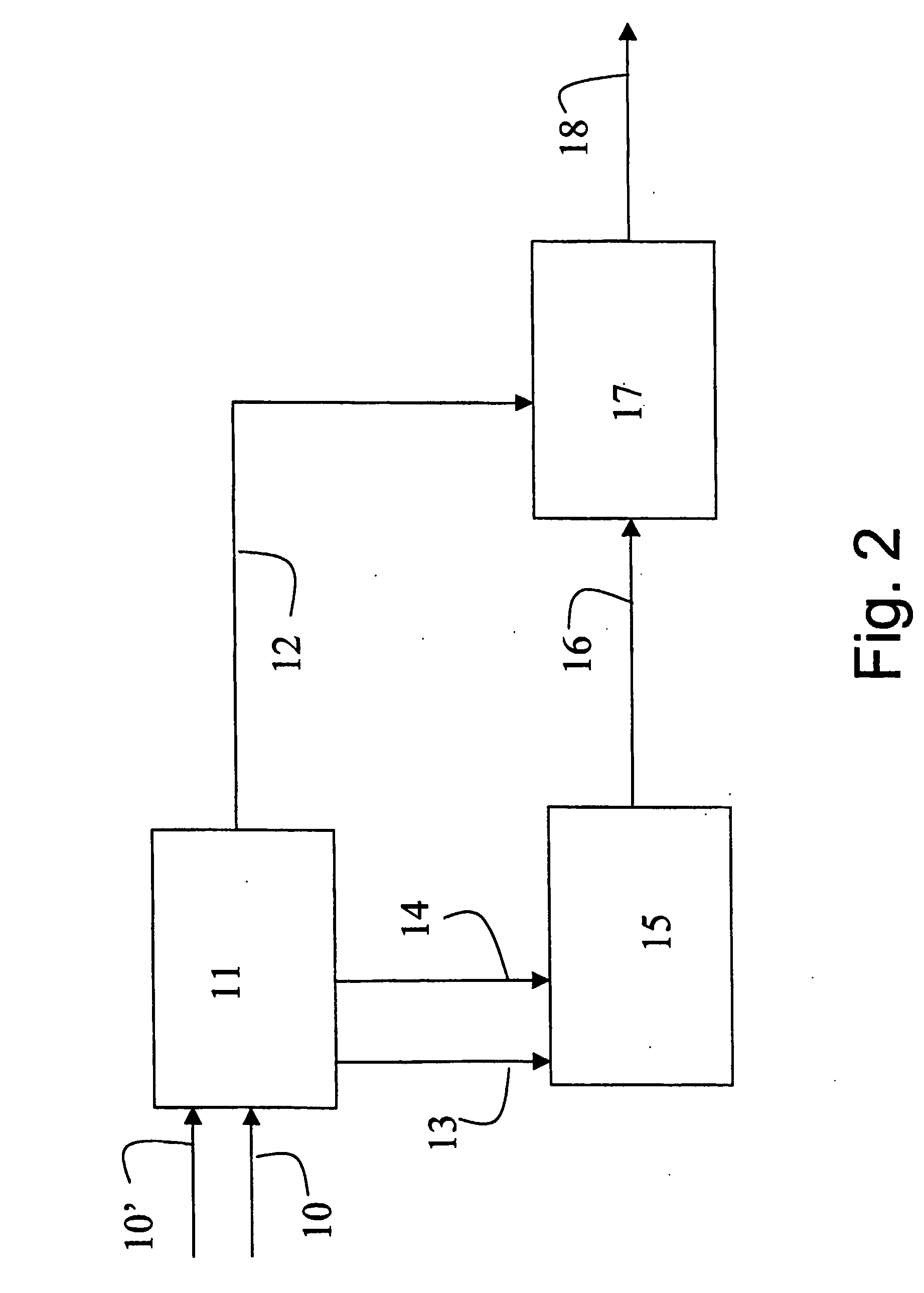

[0048]FIG. 2 illustrates a second preferred embodiment of the present invention, where hydrogen for the heavy oil upgrading and gas for injection into the reservoir is generated by autothermal reforming (ATR) of natural gas. The example is based on the same heavy oil and production volume of oil as Example 1.

[0049] Natural gas, 135 ton per hour (221.000 Sm3 per hour), is introduced through a gas line 10 and O2 (from an air separation unit) is introduced through a line 10′ into an ATR unit 11. The ATR unit 11 comprises one or more autothermal reforming reactors wherein natural gas is reformed by steam reforming combined with partial combustion. Steam reforming is, as mentioned above, an endothermal reaction and the energy required is supplied from partial combustion of a part of the natural gas in the same reactor according to the following reactions:

Steam reforming CH4+H2O═CO+3H2

Partial combustion CH4+ 3 / 2O2═CO+2H2O

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com