Lubricating oil composition

a technology of lubricating oil and composition, which is applied in the direction of lubricant composition, petroleum industry, additives, etc., can solve the problems of copper corrosion, salicylate detergents may contribute to the deterioration of nitrile rubber seal materials, etc., and achieve the effect of improving performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0110] A lubricating oil composition representing a low SAPS (sulfated ash, phosphorus, sulfur) 10W40 crankcase lubricant for a heavy duty diesel engine meeting the requirements of the ACEA E6-04 specification was prepared by blending a base stock oil of lubricating viscosity, a detergent / inhibitor (DI) package including salicylate detergent, dispersant, ZDDP and antifoamant; a viscosity modifier and LOFI (lube oil flow improver). The resulting composition had a nitrogen content of 0.16 mass %; a sulfur content of 0.25 mass %, a sulfated ash (SASH) content of 0.25 mass % and 800 ppm of phosphorus and 24 mmol of salicylate soap per kilogram of finished lubricant.

[0111] Four lubricating oil compositions were prepared based on the above recipe. Example 5, a comparative example, contained no added 450 Mn polybutene (PIB). Examples 2, 3 and 4, which represent the invention, contained 2.1, 2.5 and 3.0 mass % of 950 Mn PIB, respectively. The four samples were then tested for compatibility...

example 3

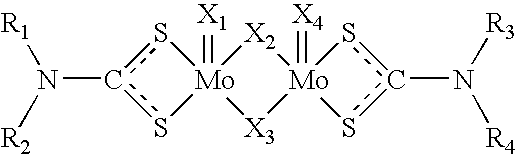

[0113] A lubricating oil composition representing a 15W40 crankcase lubricant for a heavy duty diesel engine meeting the requirements of the PC-10 specification was prepared by blending a base stock oil of lubricating viscosity, a detergent / inhibitor (DI) package including sulfonate and sulfurized phenate detergent, dispersant, ZDDP, a molybdenum-sulfur compound, and antifoamant; a dispersant / viscosity modifier and LOFI (lube oil flow improver). The resulting composition had a sulfur content of 0.31 mass %, a nitrogen content of 0.14, a SASH content of 0.94; 50 ppm of molybdenum and 1000 ppm of phosphorus.

[0114] Four lubricating oil compositions were prepared based on the above recipe. Example 9, a comparative example, contained no added 950 Mn polybutene (PIB). Examples 10, 11 and 12, which represent the invention, contained 0.5, 1.0 and 2.0 mass % of 950 Mn PIB, respectively. The four samples were then tested for compatibility with nitrile rubber in the bench tests described in E...

example 4

[0116] Five lubricating oil compositions were prepared based on the recipe provided in Example 3. Example 13, a comparative example, contained no added 950 Mn polybutene (PIB). Examples 14, 15, 16 and 17, which represent the invention, contained 2, 3, 4 and 5 mass % of 950 Mn PIB, respectively. The five samples were then tested for corrosion, particularly copper corrosion, using the High Temperature Corrosion Bench Test described in ASTM D6594. The results are shown below in Table V.

TABLE VEx. 14Ex. 15Ex. 16Ex. 12PropertyLimitEx. 13(2)(3)(4)(5)Cu 20 max1112413129Pb120 max4436373842Sn 50 max02222Cu Strip 34B1A1A1A1A

[0117] As demonstrated, the addition of PIB to a lubricating oil composition containing a significant sulfur content further improves copper corrosion performance and allows passage of the HTCBT with a formulation that fails the test in the absence of the PIB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com