Tissue engineering scaffold

a tissue engineering and scaffold technology, applied in the field of tissue engineering scaffolds, can solve the problems of difficult to provide a scaffold suitable for a range of applications, many complex problems to be overcome, and the attempts to produce 3 dimensional scaffolds of polymeric materials have not been entirely successful, so as to promote a highly desirable host response and reduce the effect of bioresorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

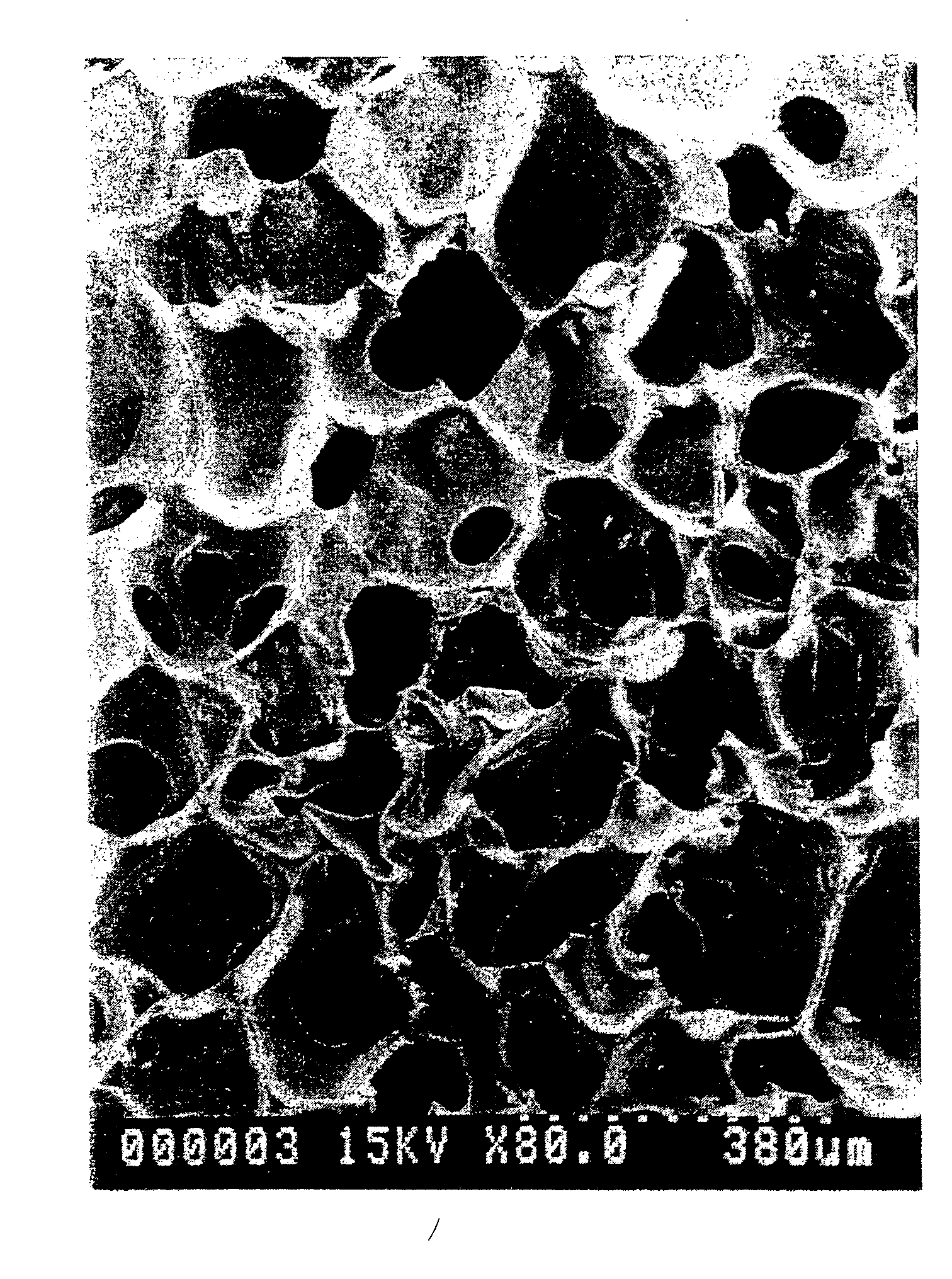

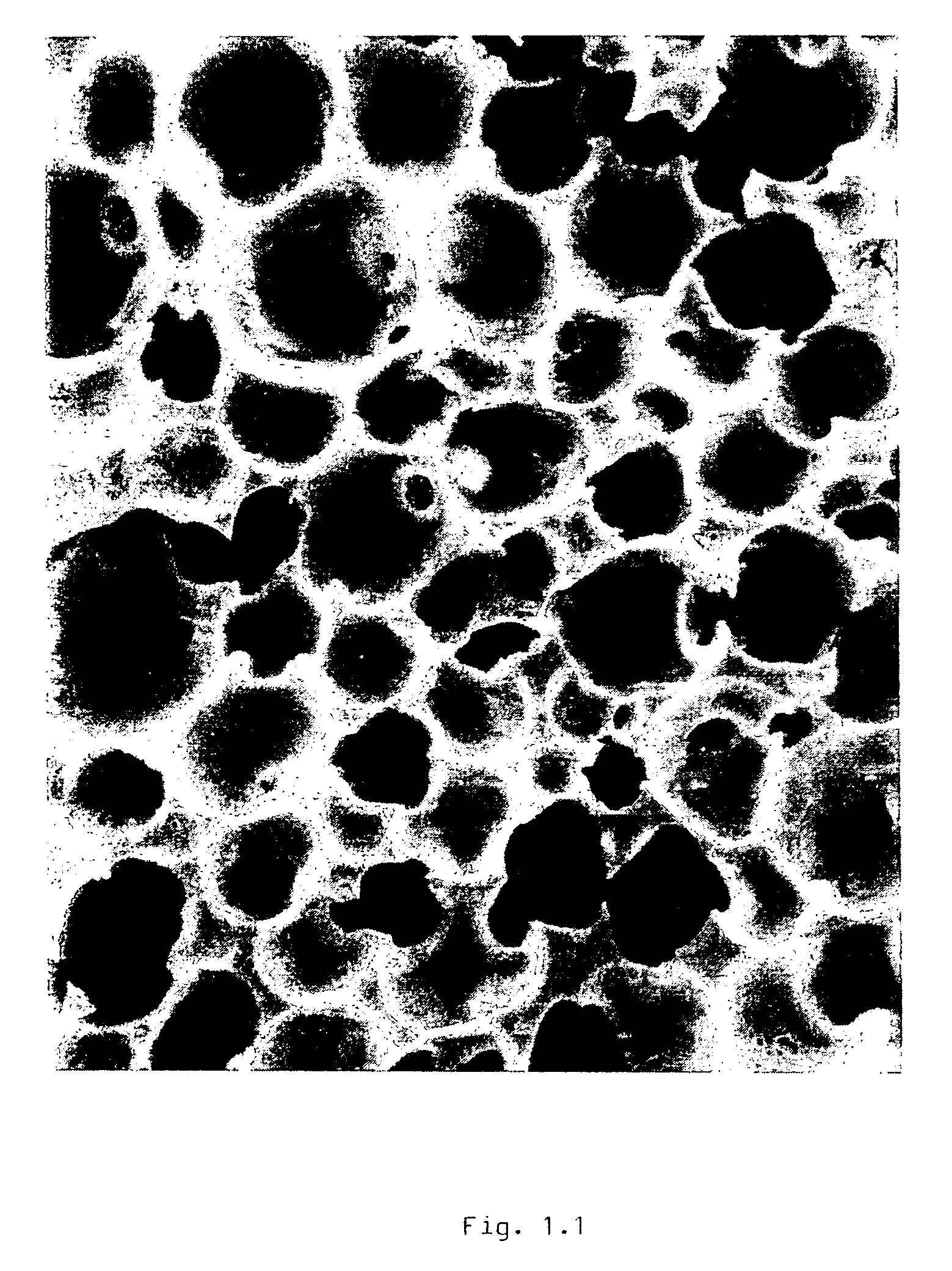

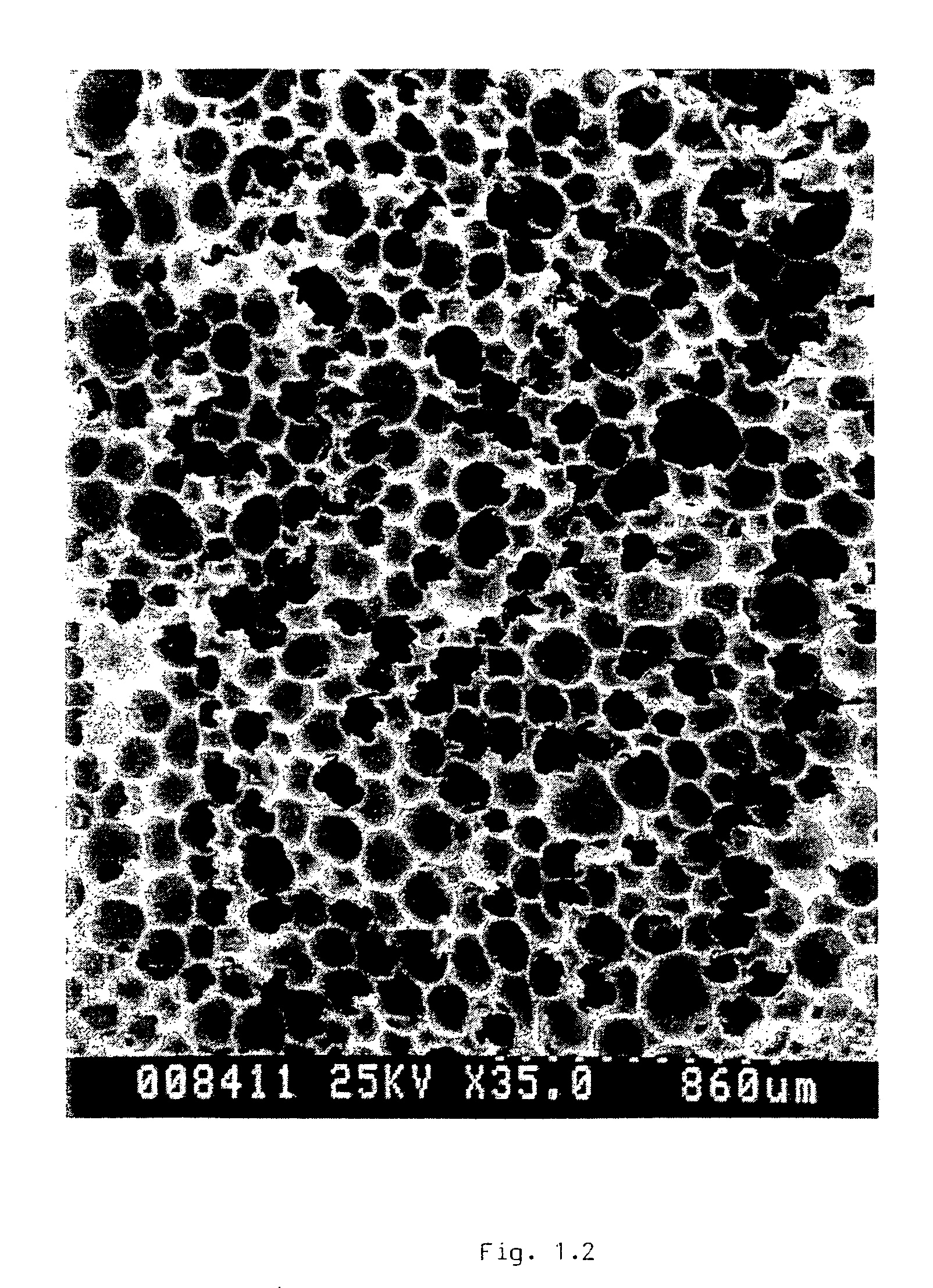

[0177] The unique features of the tissue engineering scaffolds of this invention will be demonstrated by the following examples.

example a

[0178] For the preparation of polyether urethane tissue engineering scaffold a polyol resin and an isocyanate pre-polymer are prepared. In the preparation of the polyol resin the following raw materials are added to a heated round bottom flask and mixed;

Raw materialFunctionQuantity (php)PTMEG (MW 1000)1Polyol100Triethanolamine2Cross-linking agent4.6Water3Blowing agent2.561,4 Butanediol4Chain extender8.05BF 22705Surfactant1.0RC Catalyst 1056Gelling catalyst2.96Desmorapid PP7Blowing catalyst0.34Kac / Deg8Trimerisation catalyst0.73

1Terathane (Du Pont)

2Sigma Aldrich

3Sigma Aldrich

4Sigma Aldrich

5Th GoldSchmidt

6DABCO and Diethylene Glycol (Rhein Chemie) at a ratio of 33.3:66.7

7Whitchem

8Potassium acetate and Diethylene Glycol (Sigma Aldrich) at a ratio of 30:70

[0179] The materials are mixed at 50 to 60° C. for a minimum of 25-30 minutes.

[0180] An isocyanate pre-polymer with an NCO content of 15.6% was prepared by charging flake MDI (Desmodur 44M flakes from Bayer with a 2,4′-isomer...

example b

[0202] For preparation of a polycarbonate urethane tissue engineering scaffold a polyol resin and an isocyanate pre-polymer are prepared as in Example A.

QuantityRaw materialFunction(php)Polycarbonate CX 5510 (MW 1000)1Polyol100Triethanolamine2Cross-linking agent3.6Water3Blowing agent3.0BF 22705Surfactant1.2RC Catalyst 1055Gelling catalyst1.66DABCO BL 116Blowing catalyst0.8Kac / Deg7Trimerisation catalyst0.73

1Nissei Chemical Company, Japan.

2Sigma Aldrich

3Sigma Aldrich

4Th GoldSchmidt

5DABCO and Diethylene Glycol (Rhein Chemie) at a ratio of 33.3:66.7

6Air Products

7Potassium acetate and Diethylene Glycol (Sigma Aldrich) at a ratio of 30:70

[0203] The isocyanate pre-polymer was prepared as per Example 1 using Polycarbonate CX 5510 (MW 1000) to produce a pre-polymer with an isocyanate content of 15.6%.

[0204] Polycarbonate CX5510 is a random co-polymer comprising penta methylene carbonate and hexa methylene carbonate sequences of 1000 MW.

[0205] The materials were mixed at an isocyan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| void mean diameter | aaaaa | aaaaa |

| void mean diameter | aaaaa | aaaaa |

| void mean diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com