System and Method of Hydrogen and Oxygen Production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

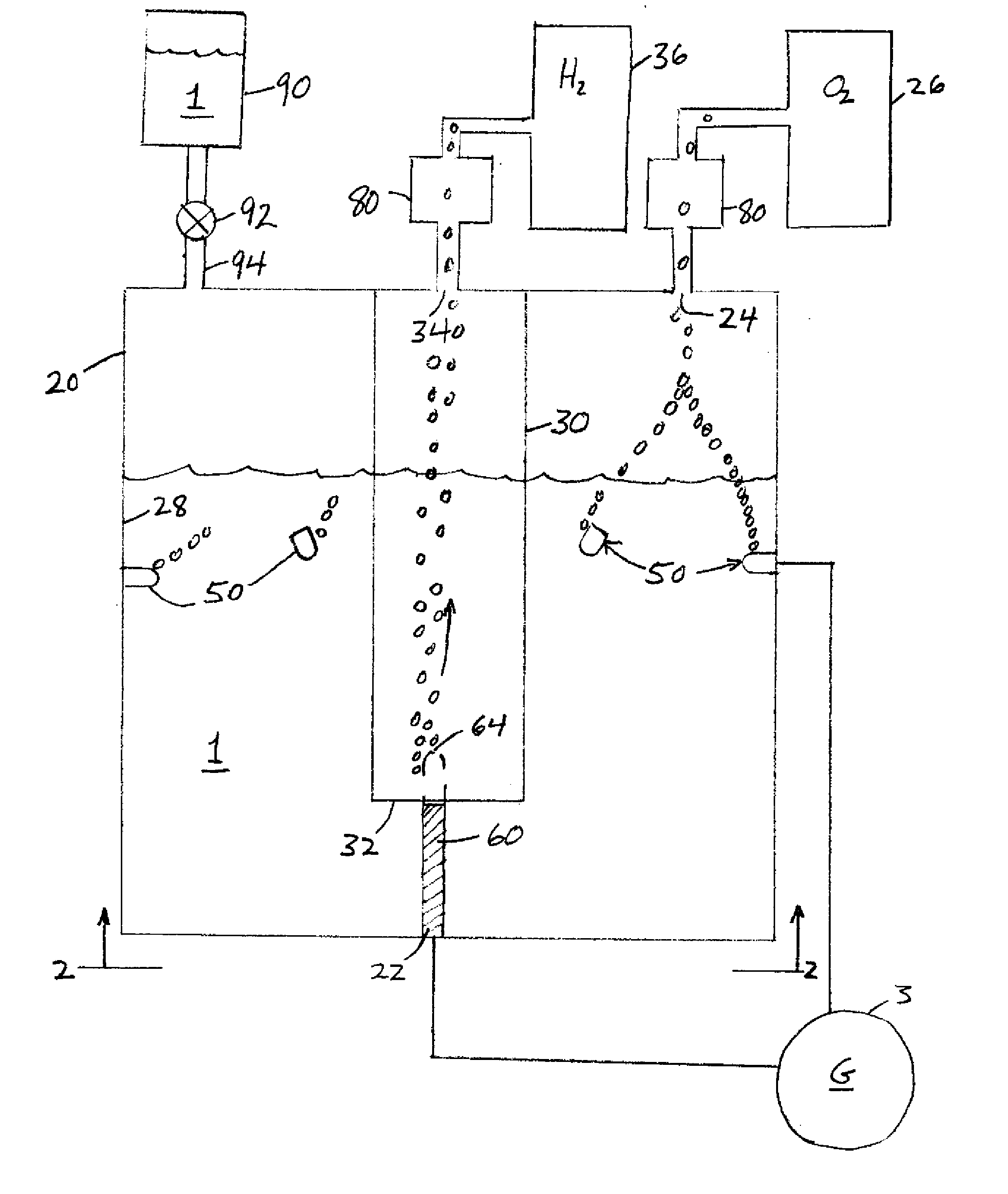

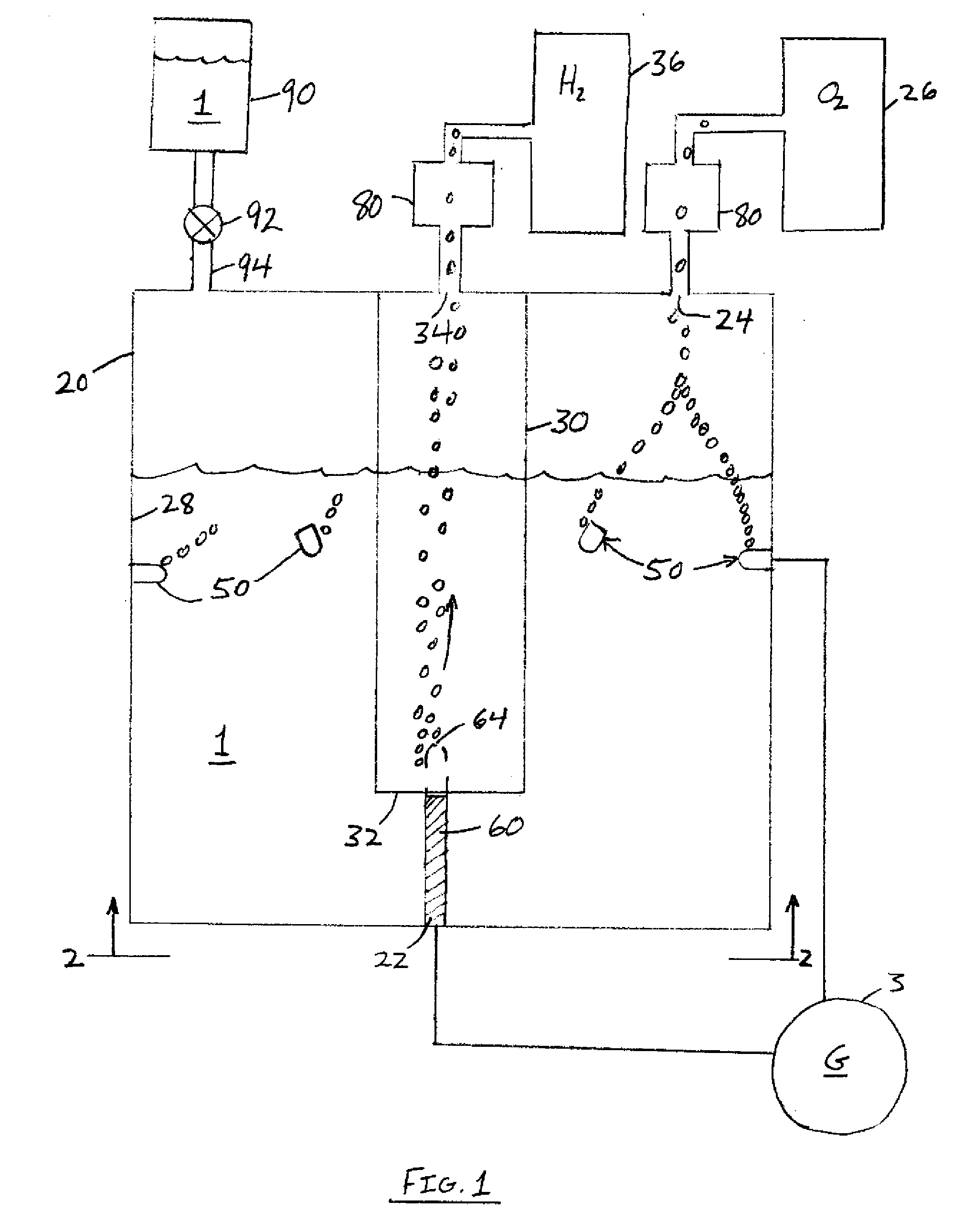

[0016] Referring now to drawing FIGS. 1-4, and in accordance with a constructed embodiment of the present invention, an apparatus 10 for the separation of hydrogen and oxygen from an aqueous fluid comprises a first chamber 20 that is capable of containing an aqueous solution or fluid 1 therein and that is substantially non-reactive with fluid 1. For purposes of the description of the present invention reference will consistently be made to production of hydrogen and oxygen by separation of an aqueous solution caused by a controlled pyrolitic reaction initiated by electrolysis. One of ordinary skill in the art will recognize that the apparatus and method described and claimed herein may be employed to produce or liberate various constituents capable of being separated through electrolytic and pyrolitic reaction mechanisms.

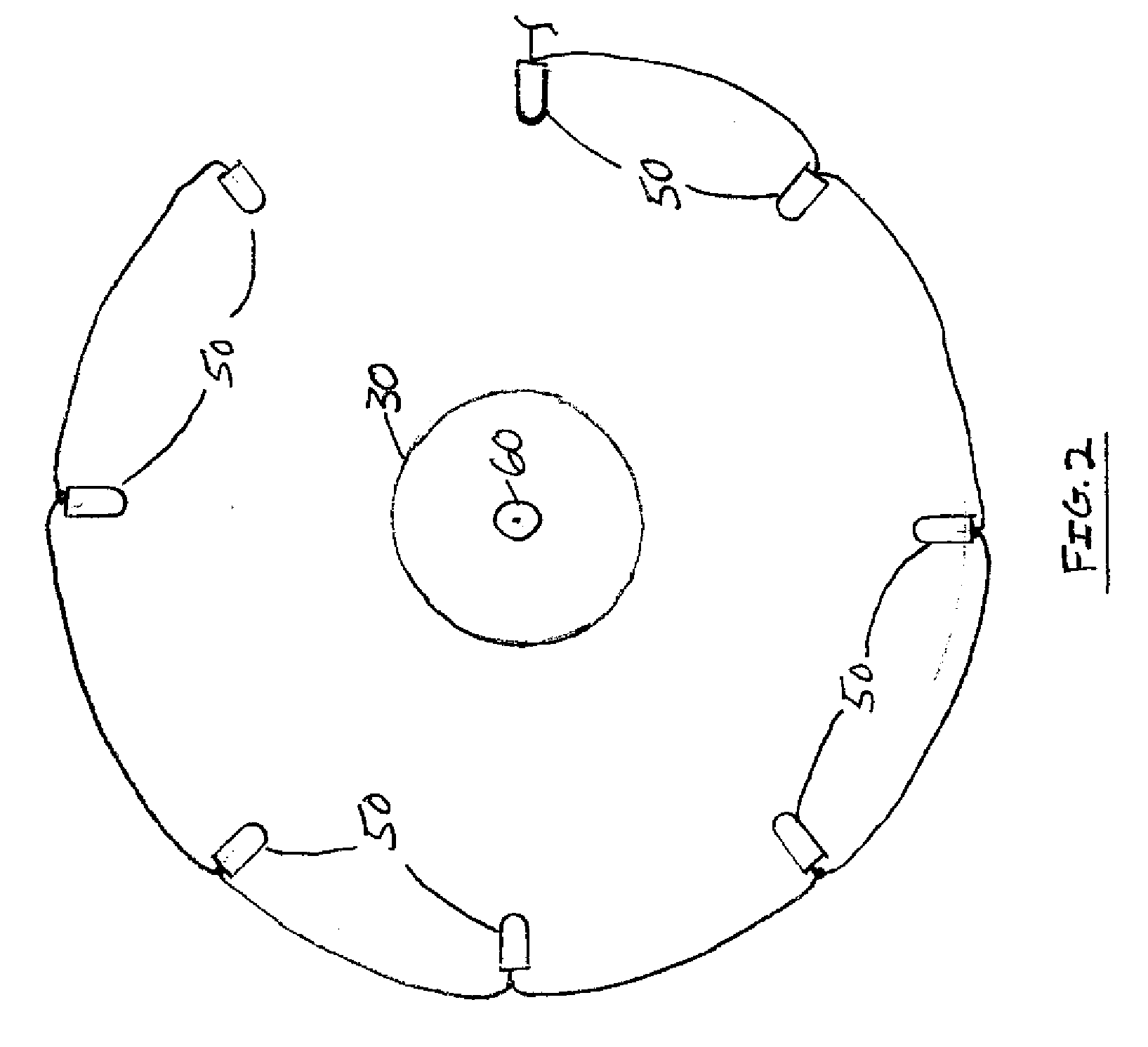

[0017] The separation apparatus 10 further comprises an inner chamber 30 that is in fluid communication with outer chamber 20 at an open portion 32 thereof to per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com