System for processing a workpiece

a workpiece and workpiece technology, applied in the field of workpiece processing system and workpiece processing system, can solve the problems of reducing the total amount of raw materials, process fluid, time, labor and effort required to manufacture microelectronic devices, defects or failures of microelectronic end products, etc., to reduce particle contamination, improve manufacturing microelectronic, and reduce the effect of end product defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

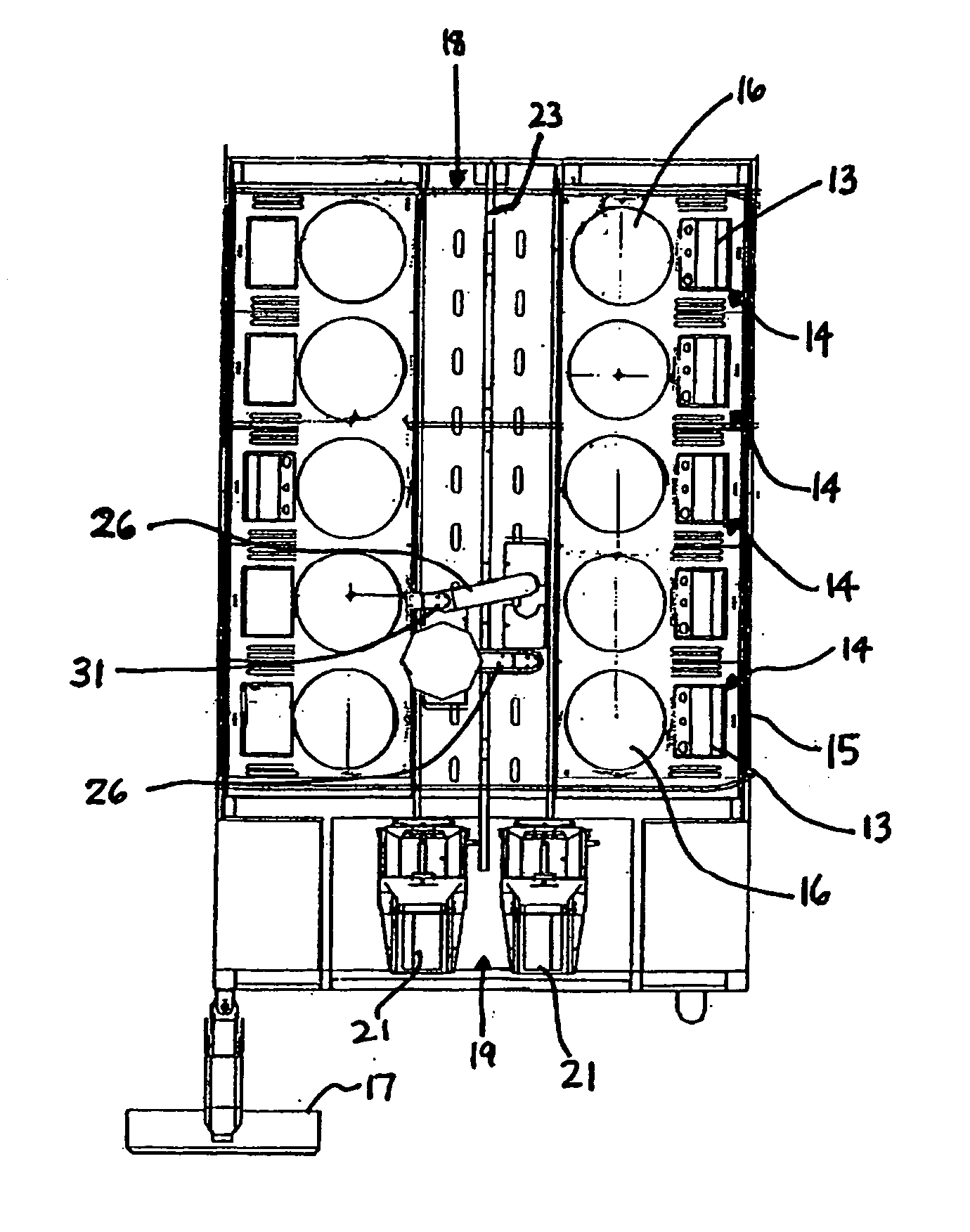

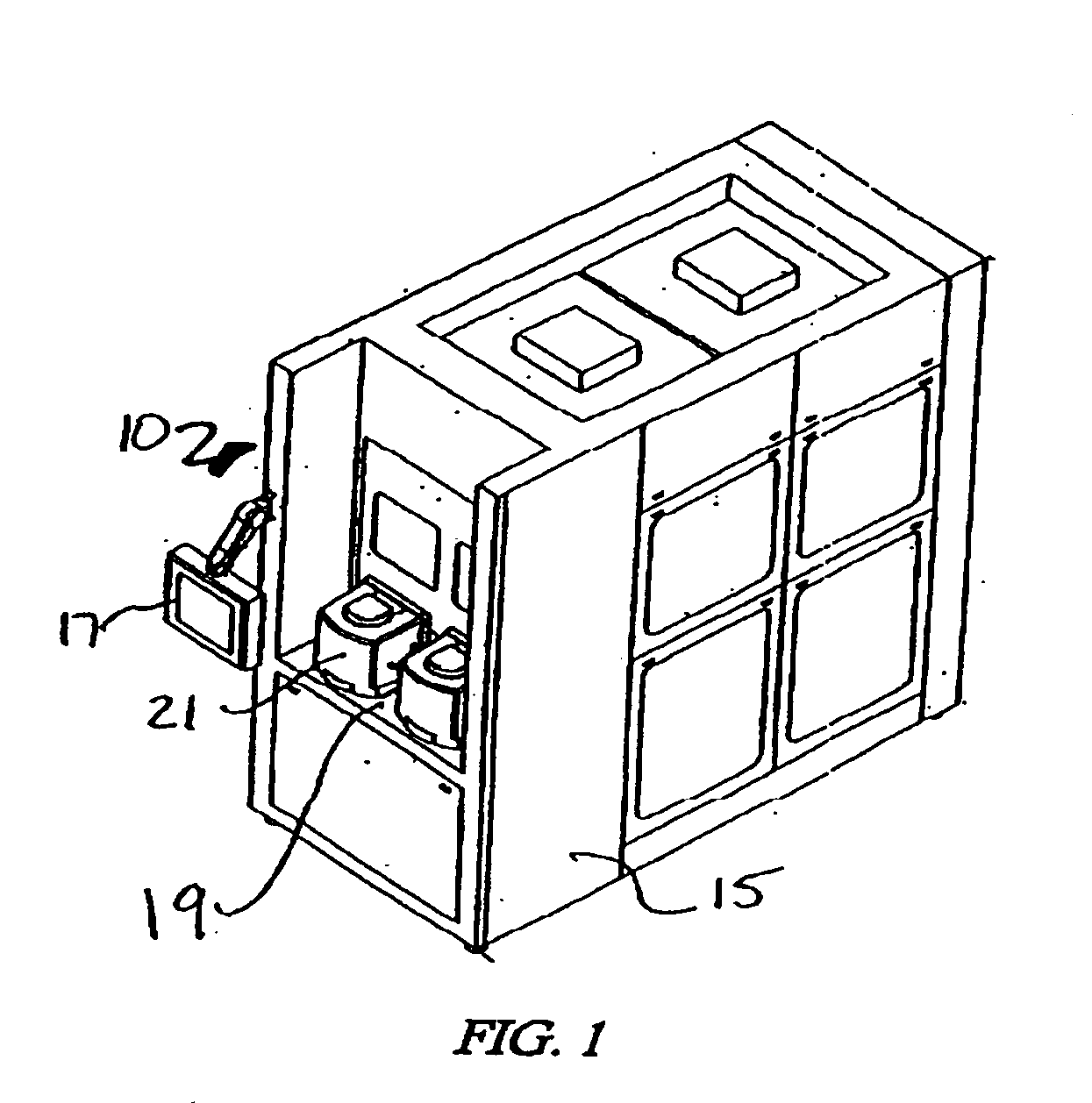

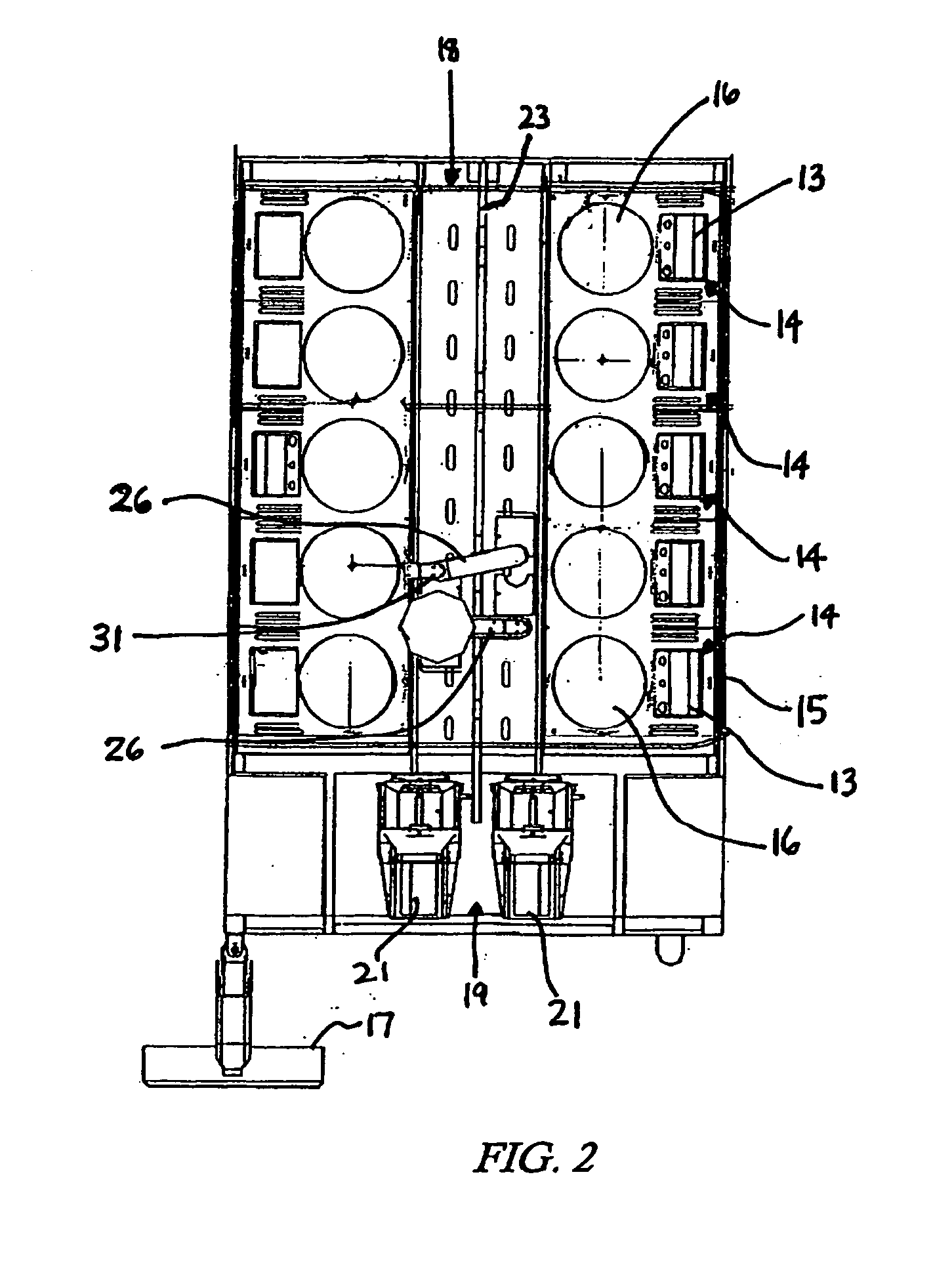

[0043] As shown in FIGS. 1-3, a processing system 10 has an enclosure 15, a control / display 17, and an input / output station 19 and a plurality of processing stations 14. Workpieces 24 are removed from carriers 21 at the input / output station 19 and processed within the system 10.

[0044] The processing system 10 includes a support structure for a plurality of processing stations 14 within the enclosure 15. At least one processing station 14 includes a workpiece processor 16 and an actuator 13 for opening and closing processor 16. The processor 16 of the present invention is designed to be utilized in a processing system 10, for example, as disclosed in pending U.S. patent application Ser. Nos. 60 / 476,786, filed Jun. 6, 2003, Ser. No. 10 / 691,688, filed Oct. 22, 2003 and Ser. No. 10 / 690,864, filed Oct. 21, 2003. These U.S. patent applications are incorporated herein by reference. System 10 may include only a plurality of processors 16 or it may include other processing modules, in addit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic force | aaaaa | aaaaa |

| magnetic repulsion force | aaaaa | aaaaa |

| vacuum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com