Carbon nanotube chain and production process for the same, target detector, and target detection method

a carbon nanotube and production process technology, applied in the field of carbon nanotube chain and production process for the same, target detector, and target detection method, can solve the problems of difficult to take a given number of carbon nanotubes and align them at regular intervals, not uniform in length, thickness, etc., and achieve high sensitivity and ease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

—Preparation of Carbon Nanotube Chain—

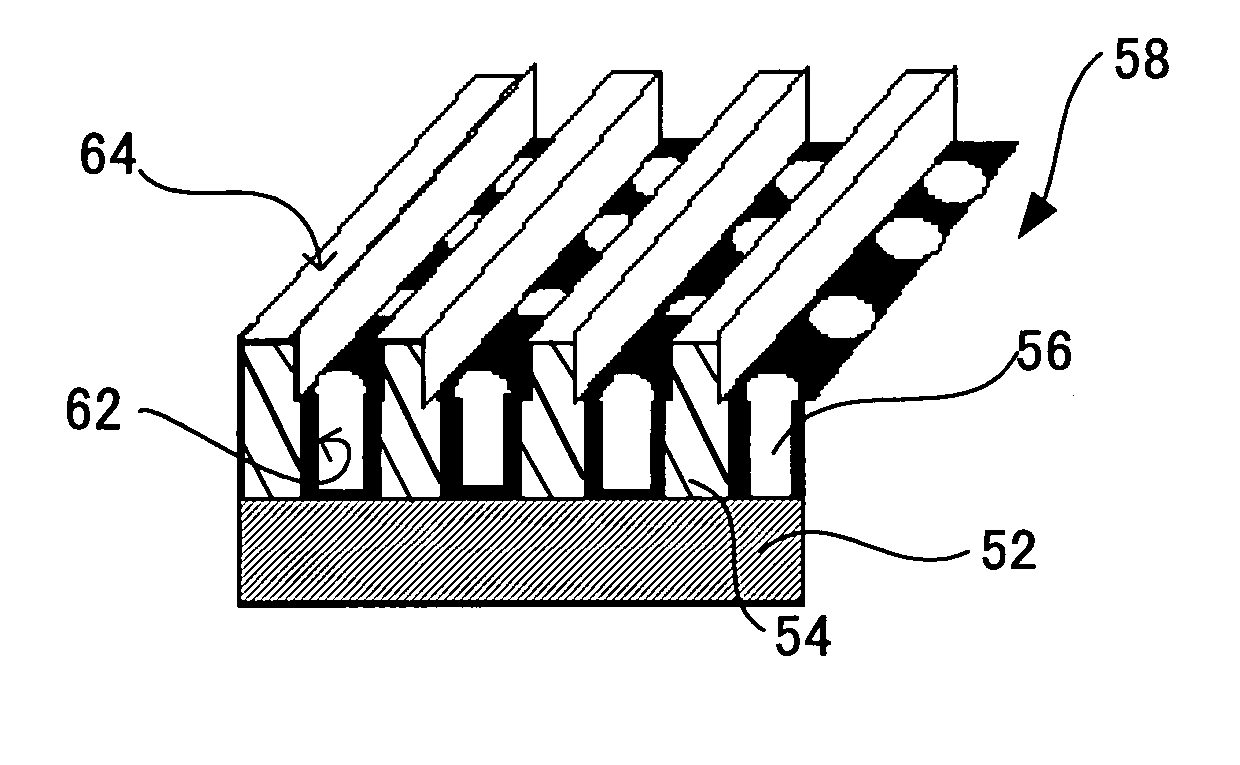

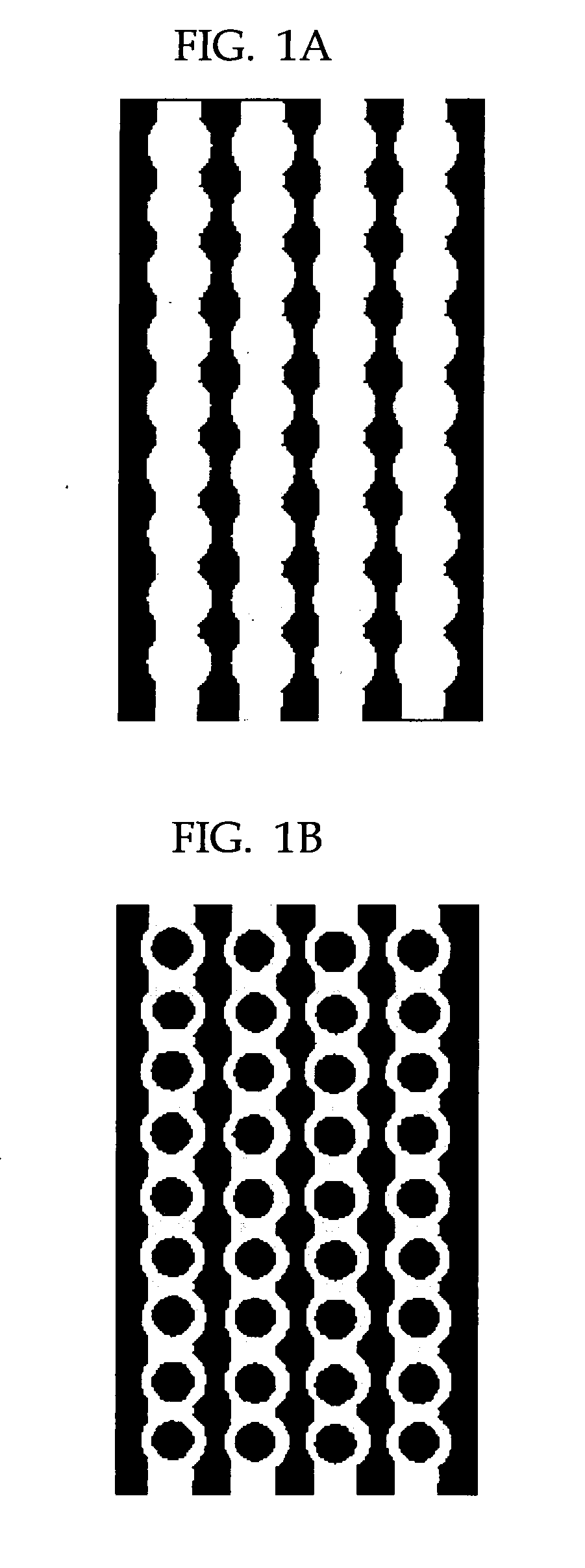

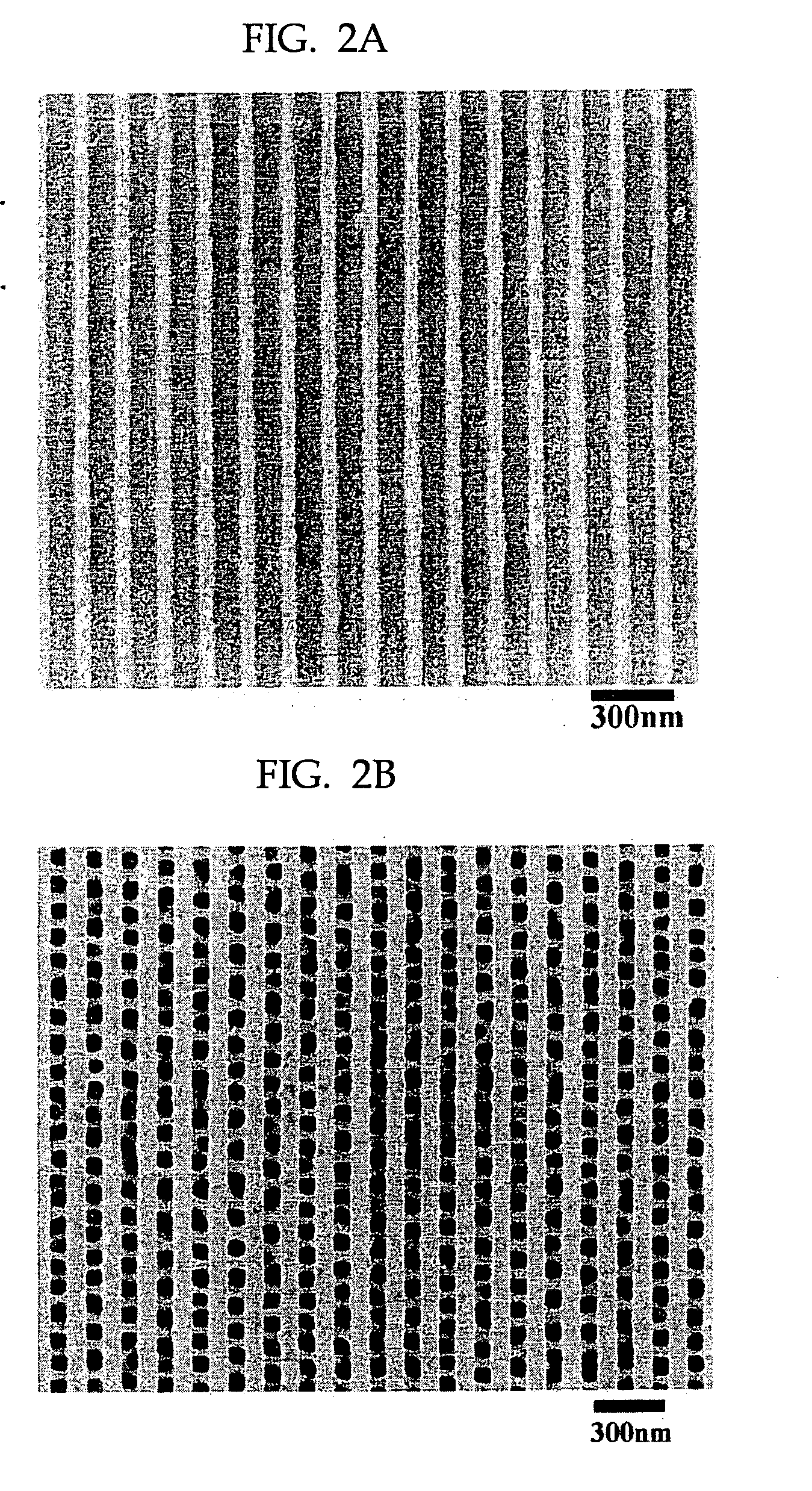

[0180] As shown in FIG. 3A, using an EB mask writer (ELS7000, manufactured by ELIONIX CO., LTD.), an EB resist was applied over a SiC substrate and lines were written to produce a pattern of concaves and convexes (lines and spaces), followed by etching treatment to obtain a SiC mold 50. Note that the interval (pitch) between adjacent concave lines (grooves) in the pattern was 150 nm, the depth of the grooves was 100 nm, and the ratio of the width of the convex or land to the width of the concave or groove, (convex width / concave width), was 1:1.

[0181] As shown in FIG. 3B, Nb was vacuum-deposited onto a silicon substrate 52 by sputtering to a thickness of 50 nm so as to form an electrode layer that is identical to that described above, and aluminum was vacuum-deposited onto the electrode layer to a thickness of 350 nm by sputtering of an aluminum sputtering target so as to form a metallic layer 54 identical to that described above. The SiC mold 5...

example 2

—Preparation of Carbon Nanotube Chain—

[0187] A carbon nanotube chain of Example 2 was prepared as in Example 1 except that the following carbon removal step was adopted.

[0188] The nanohole structure 58 having the carbon layer 60 deposited on its surface, obtained by the foregoing carbon nanotube formation step, was set to an oxygen ion beam system, wherein the ion source adopted in the system was a 20 kv ECR (Electron Cyclotron Resonance) source placed so that the incident angle of an ion beam was 45° with respect to the sample holder. As shown in FIG. 4, the nanohole structure 58 was then irradiated with a 500 eV oxygen ion beam 70 to remove the carbon layers 60 deposited on the surfaces of the lands 64 between the grooves, i.e., both the carbon layer deposited on the top surface of the lands 64 of the metallic layer 54 and the carbon layer deposited to the side surfaces of the lands 64 (see FIG. 3E).

[0189] Subsequently, as in Example 1, the metallic layer dissolving step was per...

example 3

—Preparation of Carbon Nanotube Chain—

[0190] A carbon nanotube chain of Example 3 was prepared as in Example 1 except that the following carbon removal step was adopted.

[0191] The nanohole structure 58 having the carbon layer 60 deposited on its surface, obtained by the foregoing carbon nanotube formation step, was set to an ion milling system (ME-1001, manufactured by Veeco Instruments). The nanohole structure 58 was then irradiated with an argon ion beam at an incident angel of 30° under the condition that the acceleration voltage was 50V and current density was 20 mA / cm2, to remove the carbon layers 60 deposited on the surfaces of the lands 64 between the grooves, i.e., both the carbon layer deposited on the top surface of the lands 64 of the metallic layer 64 and the carbon layer deposited to the sides of the lands 64.

[0192] Subsequently, as in Example 1, the metallic layer dissolving step was performed to provide a linear carbon nanotube chain 68 according to the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com