Apparatus and Method for NOx Reduction

a technology of emission control device and internal combustion engine, which is applied in the direction of mechanical apparatus, engine components, machines/engines, etc., can solve the problems of nox emissions from internal combustion engine vehicles, put considerable effort toward meeting, and exhaust is too oxygen-rich for three-way catalysts to be effective, so as to achieve the effect of improving the control of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

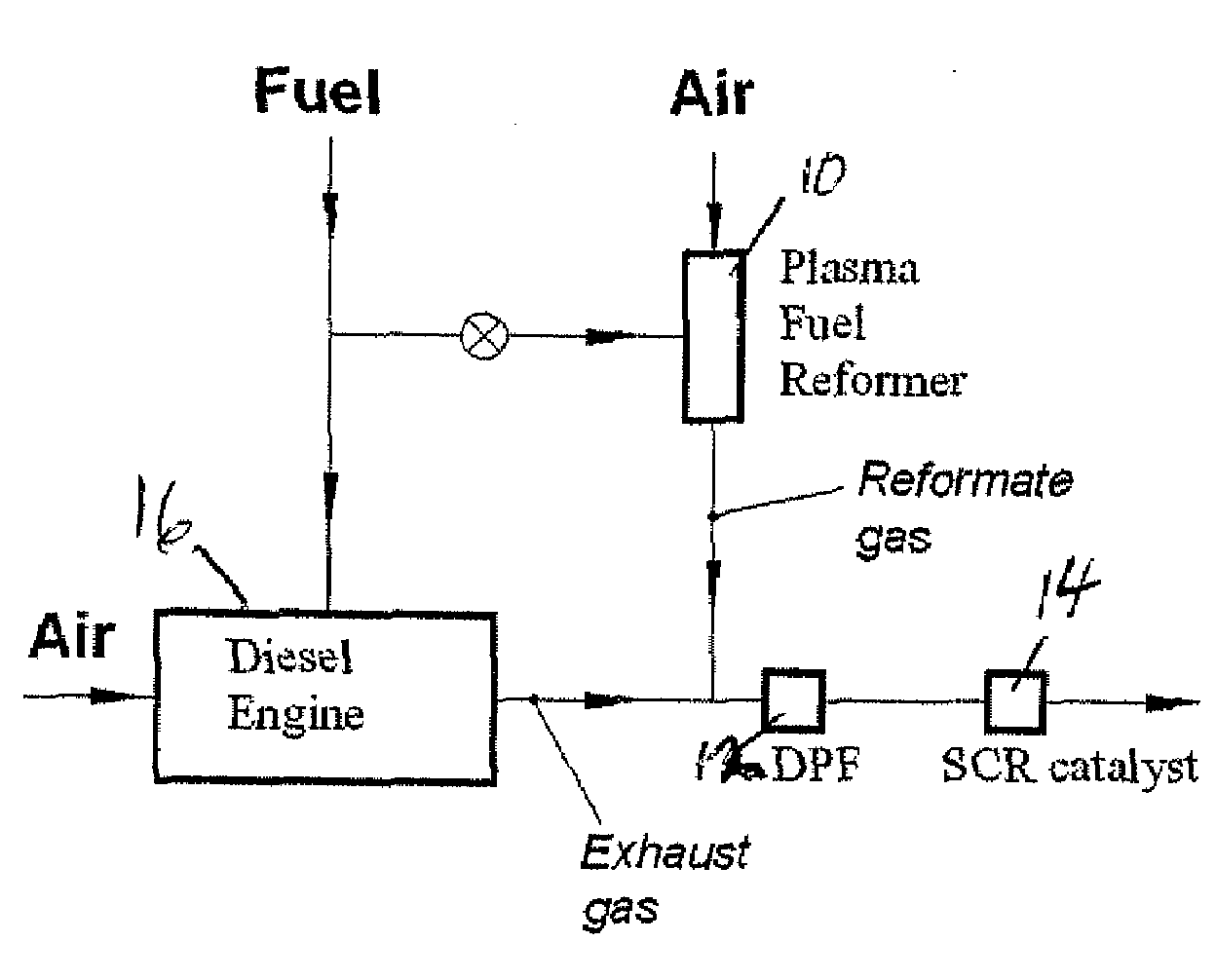

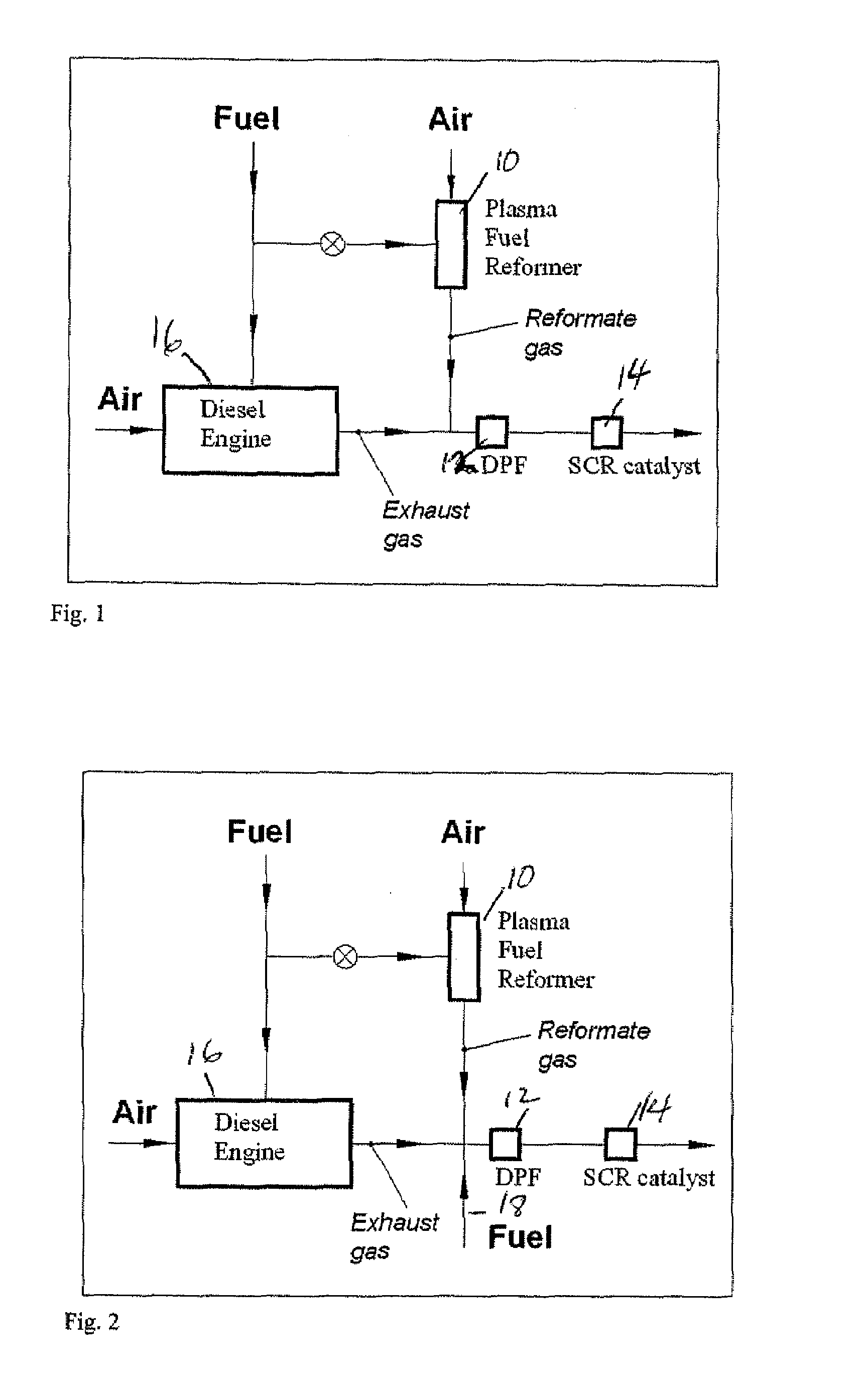

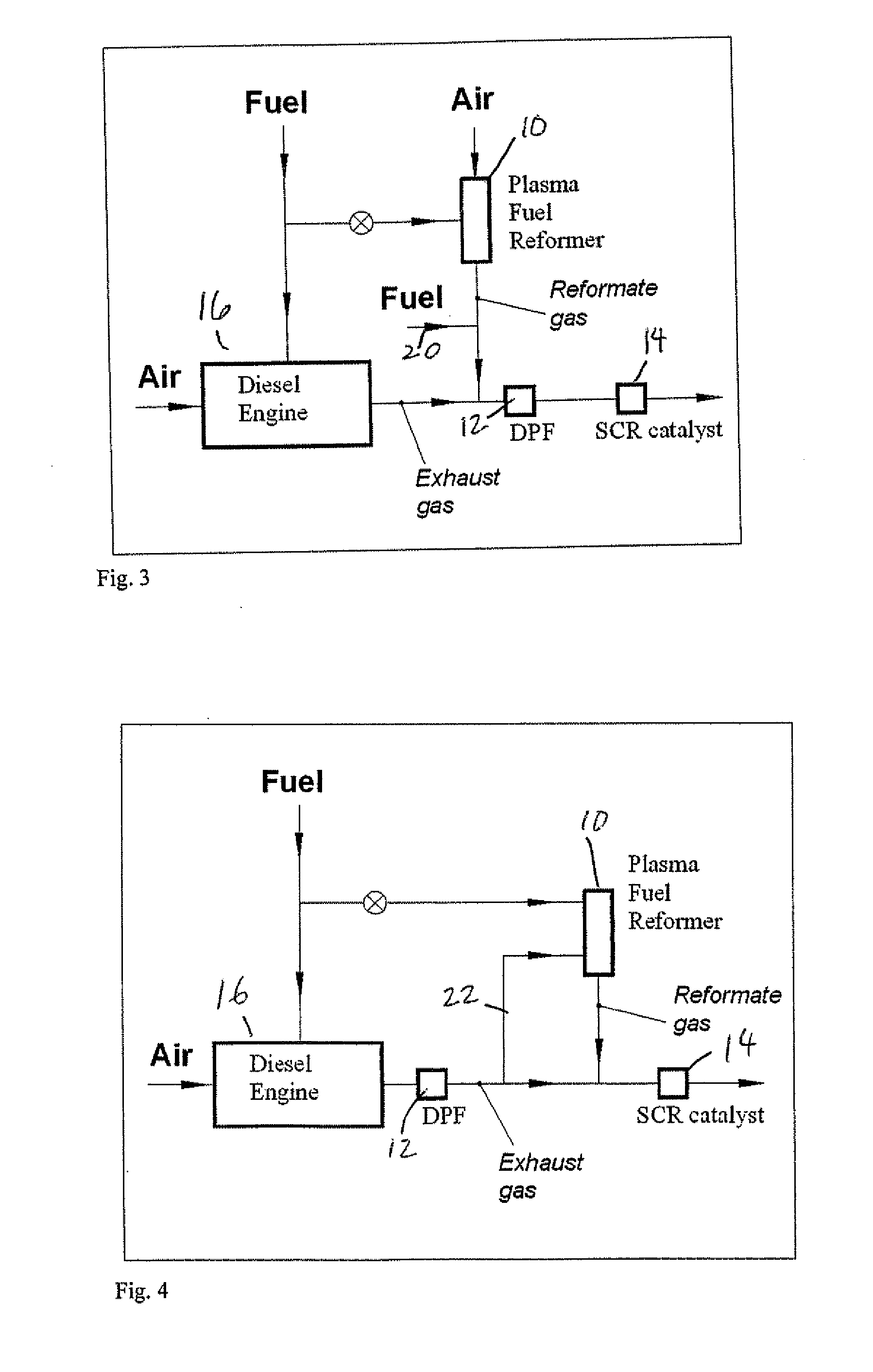

[0040]The proposed system includes an internal combustion engine or a turbine as a source of emissions, a multi-mode plasma fuel processor, selective catalytic reduction (SCR) catalyst and means to implement a predetermined control algorithm.

[0041]The SCR catalyst suitable for this system is usually a silver / alumina catalyst. The fuel processor is able to process liquid hydrocarbon fuel such as diesel or petrol to deliver the reducing agent in required quantity and of required composition while operating in a certain sequence of the following modes in accordance with a predetermined control algorithm: partial oxidation (POX), incomplete pyrolysis, evaporation, combustion, atomization.

[0042]The fuel processor could be based on one of the plasmatrons described in a U.S. patent application No. 11 / 330,515 entitled “Plasma Reformer With Extended Volume Discharge” and U.S. patent application No. 11 / 352,138 entitled “High Enthalpy Low Power Plasma Reformer”.

[0043]The system can also be equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com