Manufacturing method of semiconductor device

a manufacturing method and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device details, electrical devices, etc., can solve the problems of increasing the number of required masks, difficulty in cost reduction, complex processing procedures, etc., and achieve the effect of reducing the number of masks and the number of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The present invention will be described with reference to the accompanying drawings.

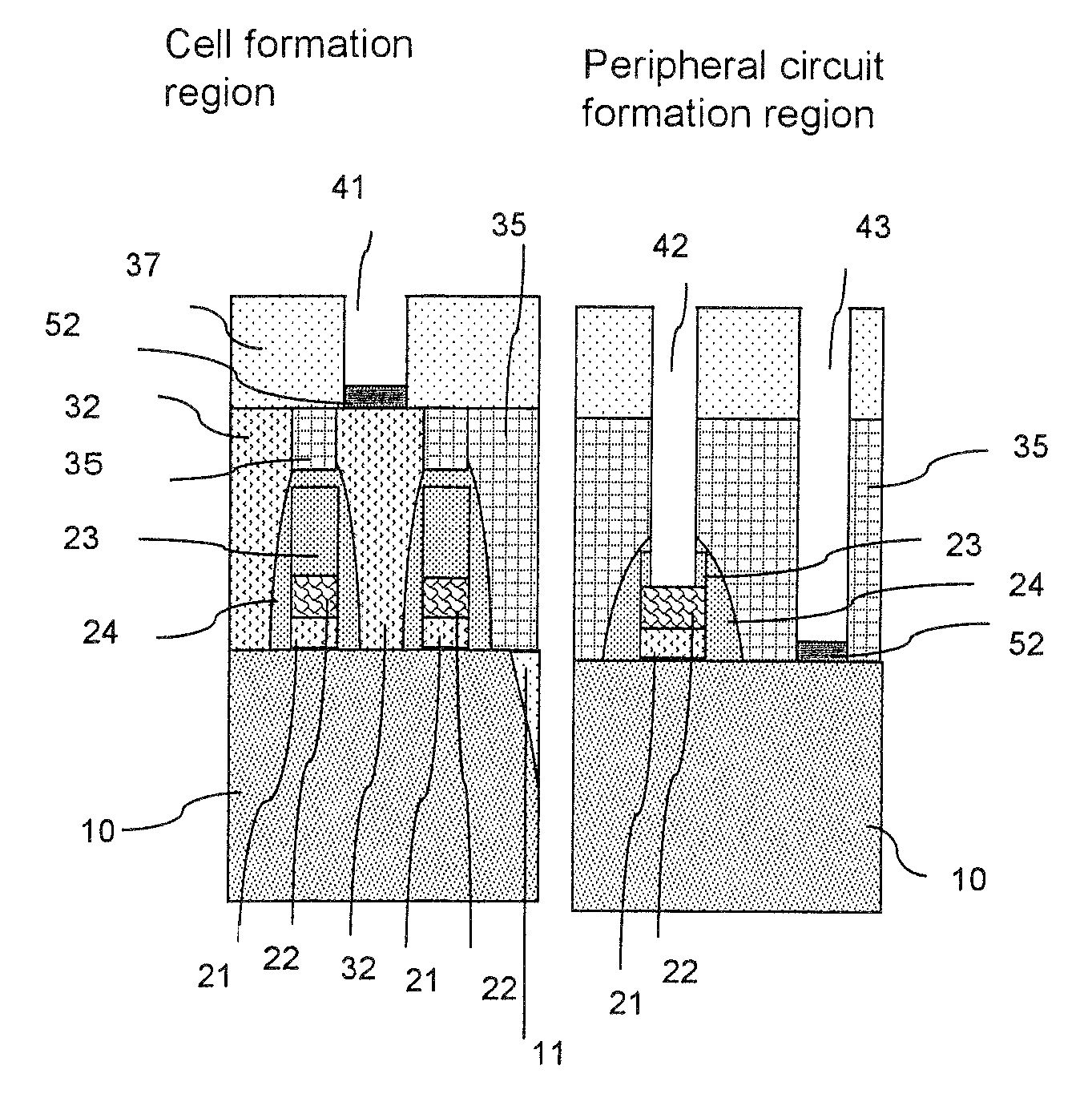

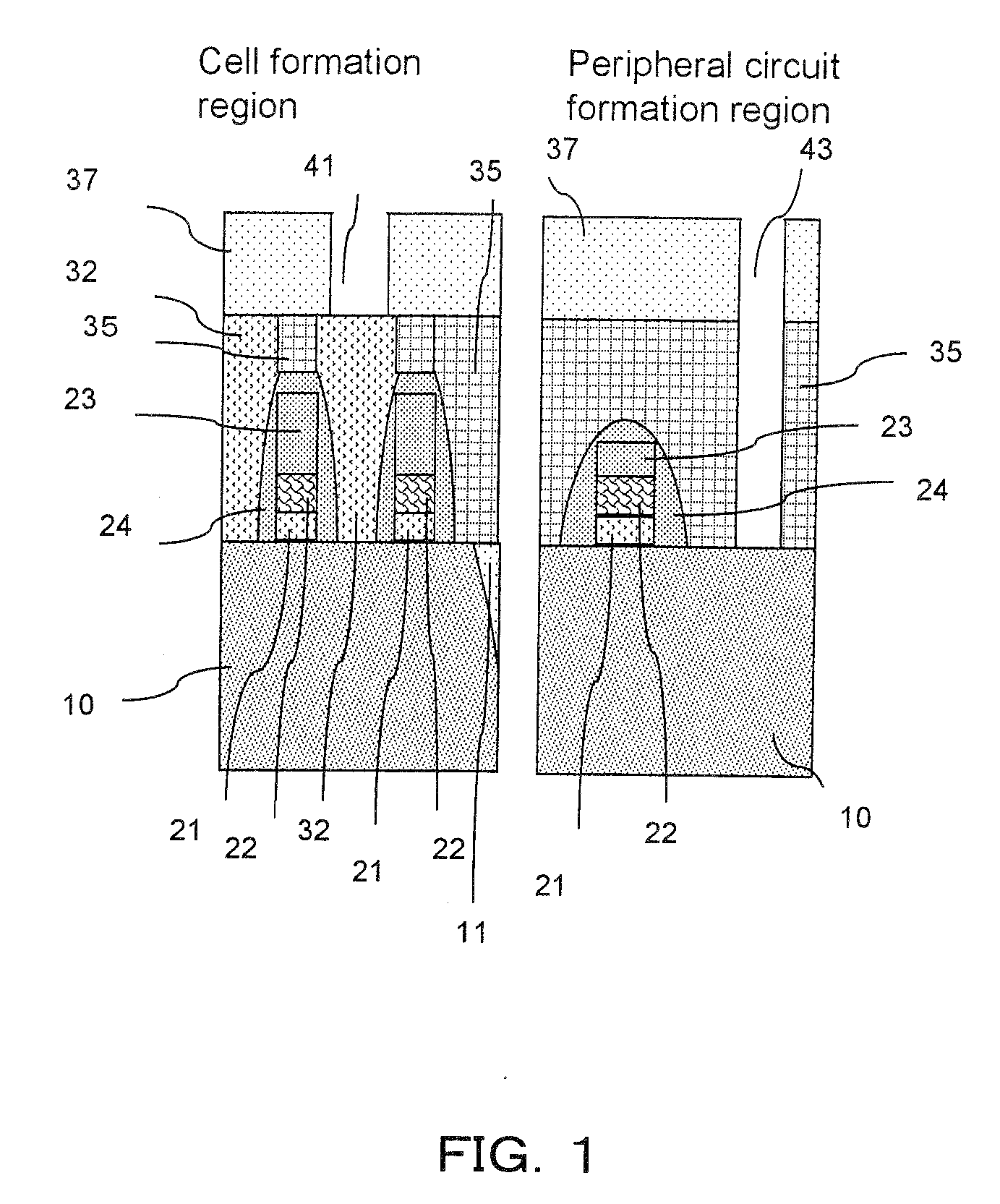

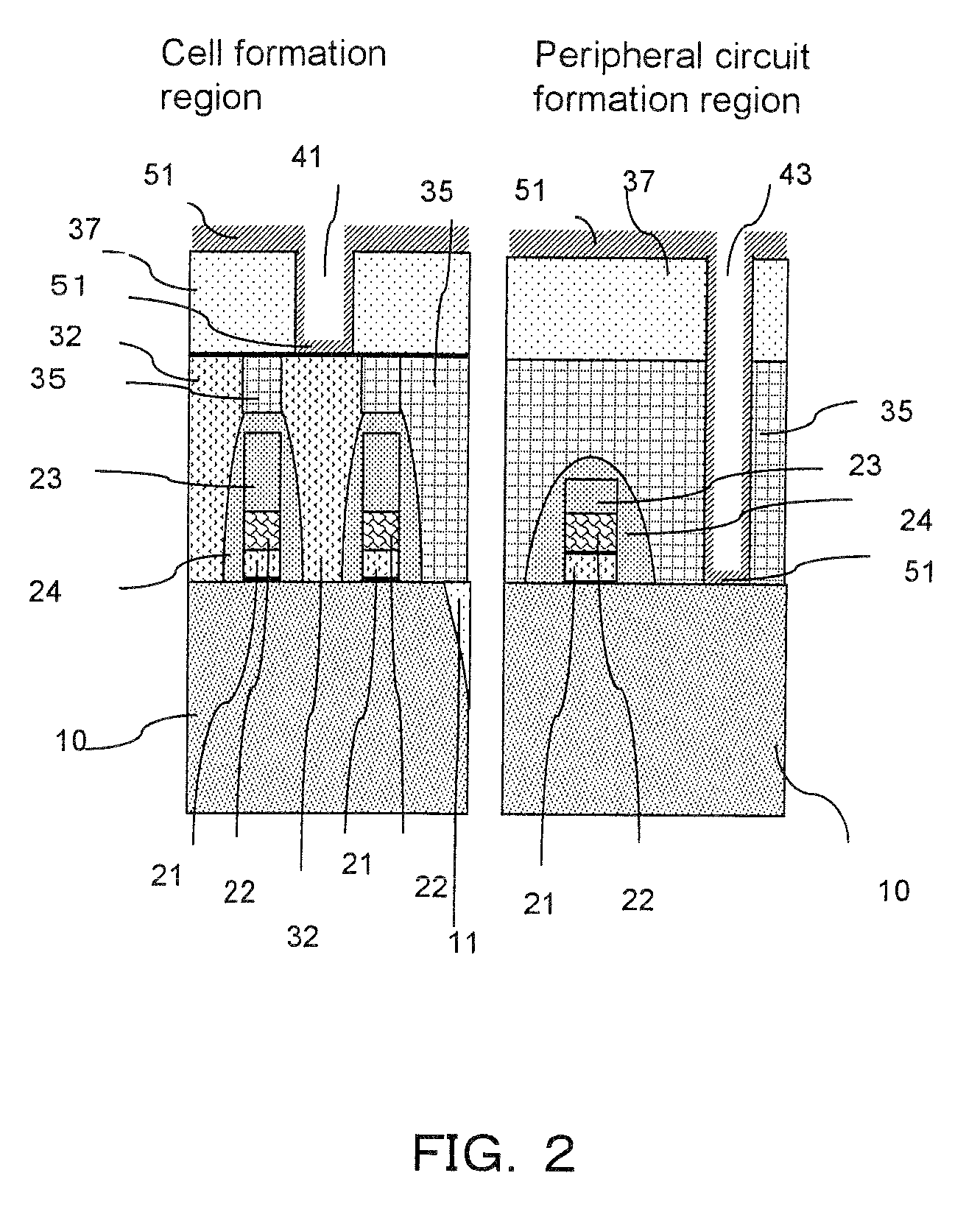

[0036]FIGS. 7 to 10 are cross-sectional views showing a exemplary embodiment of the present invention. These figures show part of a memory cell formation region (left side) and part of a peripheral circuit formation region (right) in respective steps of a DRAM device manufacturing process. Specifically, the left side of each of the drawings shows a region of a memory cell where a capacitance structure is formed later to store information. The right side shows a region to be a circuitry to control the read and write of information in the memory cell for each bit (for each “0” or “1” data).

[0037]FIG. 7 shows a structure, to which the exemplary embodiment is to be applied, and which has not been formed with openings yet. Prior to formation of the structure, a laminated structure is prepared which includes a gate insulating film (silicon oxide film) (not shown), a polysilicon film, tungsten nitride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com