Two-Component Curable Solventless Adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

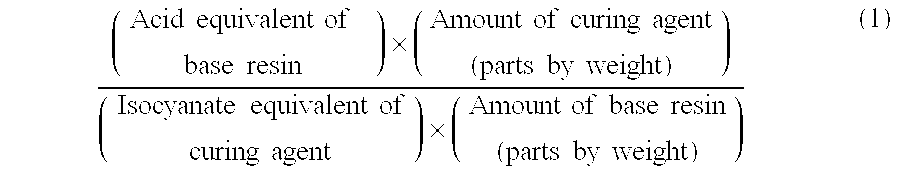

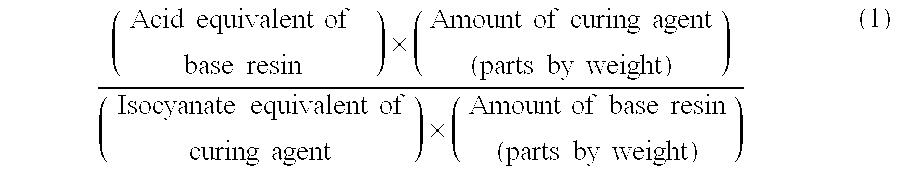

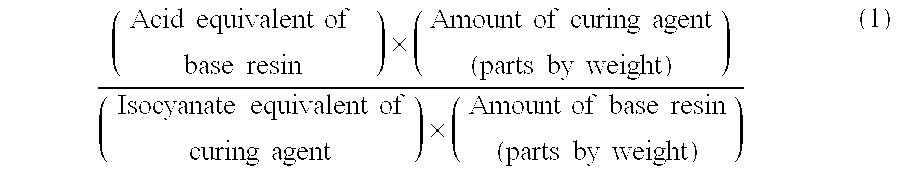

Method used

Image

Examples

preparation example 1

Preparation of Polyesterpolyol A

[0101]684.00 g of isophthalic acid, 602.21 g of 1,3-butanediol, 181.26 g of 1,6-hexanediol and 162.91 g of neopentyl glycol were charged in a reactor and an esterification reaction was performed under a nitrogen gas stream at 190 to 220° C. After a predetermined amount of water was distilled off, 200.57 g of adipic acid, 277.57 g of sebacic acid and 0.18 g of stannous octoate (Stanoct) were added and an esterification reaction was performed under a nitrogen gas stream at 180 to 220° C. to obtain a polyesterpolyol A.

preparation example 2

Preparation of Terminal Acid-Modified Polyesterpolyol B

[0102]1000 g of the polyesterpolyol A was acid-modified at 110° C. by adding 1 g of trimellitic anhydride to obtain a polyesterpolyol B.

[0103]In the resulting polyesterpolyol B, a proportion of an acid group (the proportion modified with an acid anhydride among the entire terminal hydroxyl groups) was 0.2% and a secondary or tertiary terminal hydroxyl group accounted for 95% of the entire terminal hydroxyl groups.

preparation example 3

Preparation of Terminal Acid-Modified Polyesterpolyol C

[0104]702.91 g of isophthalic acid, 585.00 g of 1,3-butanediol, 176.09 g of 1,6-hexanediol and 158.26 g of neopentyl glycol were charged in a reactor and an esterification reaction was performed under a nitrogen gas stream at 190 to 220° C. After a predetermined amount of water was distilled off, 206.11 g of adipic acid, 285.24 g of sebacic acid and 0.18 g of stannous octoate were added and an esterification reaction was performed under a nitrogen gas stream at 180 to 220° C., followed by cooling to 110° C. The reaction product was acid-modified at 110° C. by adding 12.60 g of trimellitic anhydride to obtain a polyesterpolyol C.

[0105]In the resulting polyesterpolyol C, a proportion of an acid group (the proportion modified with an acid anhydride among the entire terminal hydroxyl groups) was 1.8% and a secondary or tertiary terminal hydroxyl group accounted for 95% of the entire terminal hydroxyl groups.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com