Preparation method and application of block polymer

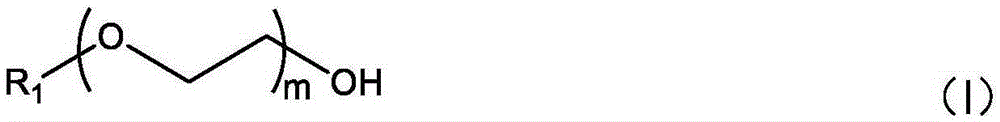

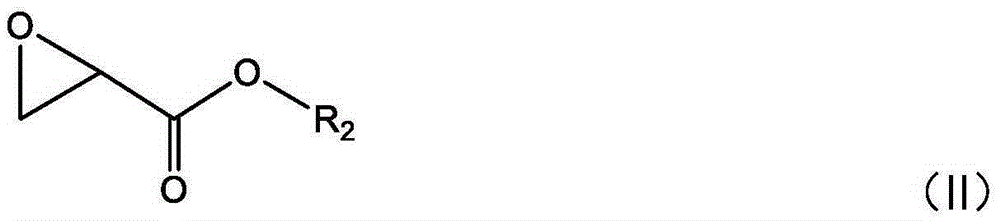

A block polymer and compound technology, applied in the field of block polymer preparation, can solve the problems of complex operation process, harsh polymerization conditions, low polymerization conversion rate, etc., to achieve controllable reaction process, simple operation process, and raw material conversion high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

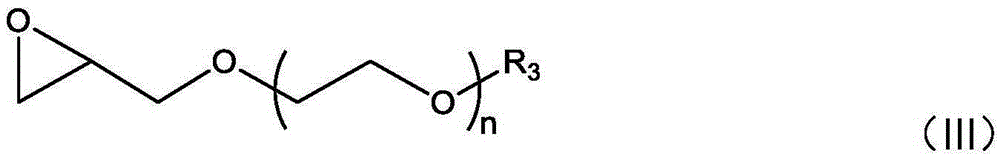

[0041] Preparation of Compound C:

[0042] Add 0.5 mol of epichlorohydrin, 0.2 mol of sodium hydroxide, 0.005 mol of phase transfer catalyst tetra-n-butylammonium bisulfate, 0.05 mol of monoalkyl polyethylene glycol in a three-necked flask with stirring, and keep the temperature at 60 ℃, stirred rapidly for 5h, filtered, and the filtrate was distilled under reduced pressure to remove excess epichlorohydrin, and the product was tested by HPLC. The conversion rate of monoalkyl polyethylene glycol was 85% to 90%. Ethyl acetate is the eluent) for separation and purification to obtain epoxy-terminated alkyl polyethylene glycol with a purity greater than 99% (see Table 1 for specific parameters).

[0043] Summary of epoxy-terminated alkyl polyethylene glycol prepared in table 1

[0044] the code

Embodiment 1

[0046] The mole number of compound A is 4% of the total mole number of compound B and compound C, and the molar ratio of compound B to compound C is 0.505:1.

[0047] In a dry 2L reactor with stirring, add 12.12g of ethylene glycol monomethyl ether and 1.61g of sodium metal, stir until the sodium metal is completely dissolved, and seal the reactor. Repeat the following operation twice: after vacuuming, replace with nitrogen to a pressure of 0.01MPa. Then start stirring and raise the temperature to 80-100°C, keep the reaction pressure at 0-0.05MPa, and continuously and slowly add 136.5g of methyl glycidic acid dropwise into the reactor at a uniform speed for 4 hours while maintaining the reaction temperature at 80-100°C. 100°C; after the feeding is completed, continue to maintain the constant temperature for 0.5h, and then continuously and dropwise add 1457.5g of compound C-1 to the reactor at a uniform speed for 5h, while maintaining the reaction temperature at 80-100°C; after...

Embodiment 2

[0049] The mole number of compound A is 2.1% of the total mole number of compound B and compound C, and the molar ratio of compound B to compound C is 0.806:1.

[0050] In a dry 2L reactor with stirring, add 7.45g of ethylene glycol monoethyl ether and 3.99g of sodium methoxide, stir until the sodium methoxide is completely dissolved, and seal the reactor. Repeat the following operation twice: after vacuuming, replace with nitrogen to a pressure of 0.02MPa. Then start stirring and heat up to 100-120°C, keep the reaction pressure at 0-0.05MPa, and continuously and dropwise add 211.49g of ethyl glycidate to the reactor at a uniform speed for 6 hours while keeping the reaction temperature at 100- 120°C; after the feeding is completed, continue to maintain the constant temperature for 1 hour, and then continuously and dropwise add 1378.5g of compound C-2 to the reactor at a uniform speed for 8 hours, while maintaining the reaction temperature at 100-120°C; after the end of the fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com