Quench liquids and washing systems for production of microparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0103]Microparticles were prepared using a 105 gram batch size coacervation process. The composition and volume of the quench liquid and the composition of the microparticle washing system were varied. The resulting microparticles were characterized with respect to yield, particle size, and residual solvents.

A. Inner Water-In-Oil Emulsion Formation

[0104]A water-in-oil emulsion was created with the aid of a sonicator (Vibracell VCX 750 with a ½″ probe (part #A07109PRB; Sonics and Materials Inc., Newtown, Conn.). The water phase of the emulsion was prepared by dissolving 2.1 g sucrose in 63 g water. The oil phase of the emulsion was prepared by dissolving PLG polymer (97.7 g of purified 50:50 DL4A PLG (Alkermes)) in methylene chloride (1530 g or 6% w / v)). The inner emulsion was formed by adding the water phase to the oil phase while stirring at 1400 to 1600 rpm and sonicating at 100% amplitude over about a five minute period at 2-8° C. The sonication scheme was 2 minutes of sonication...

example 2

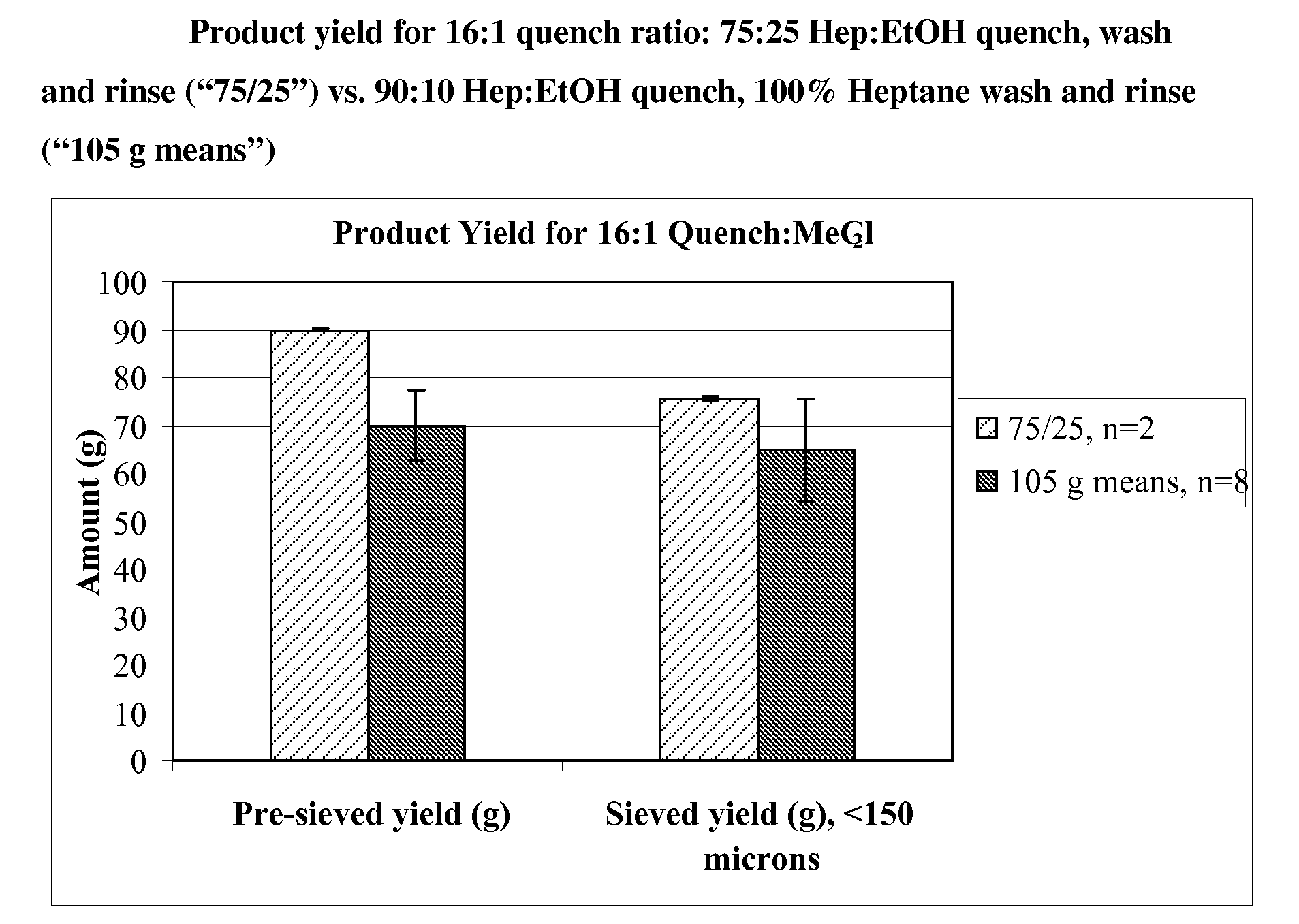

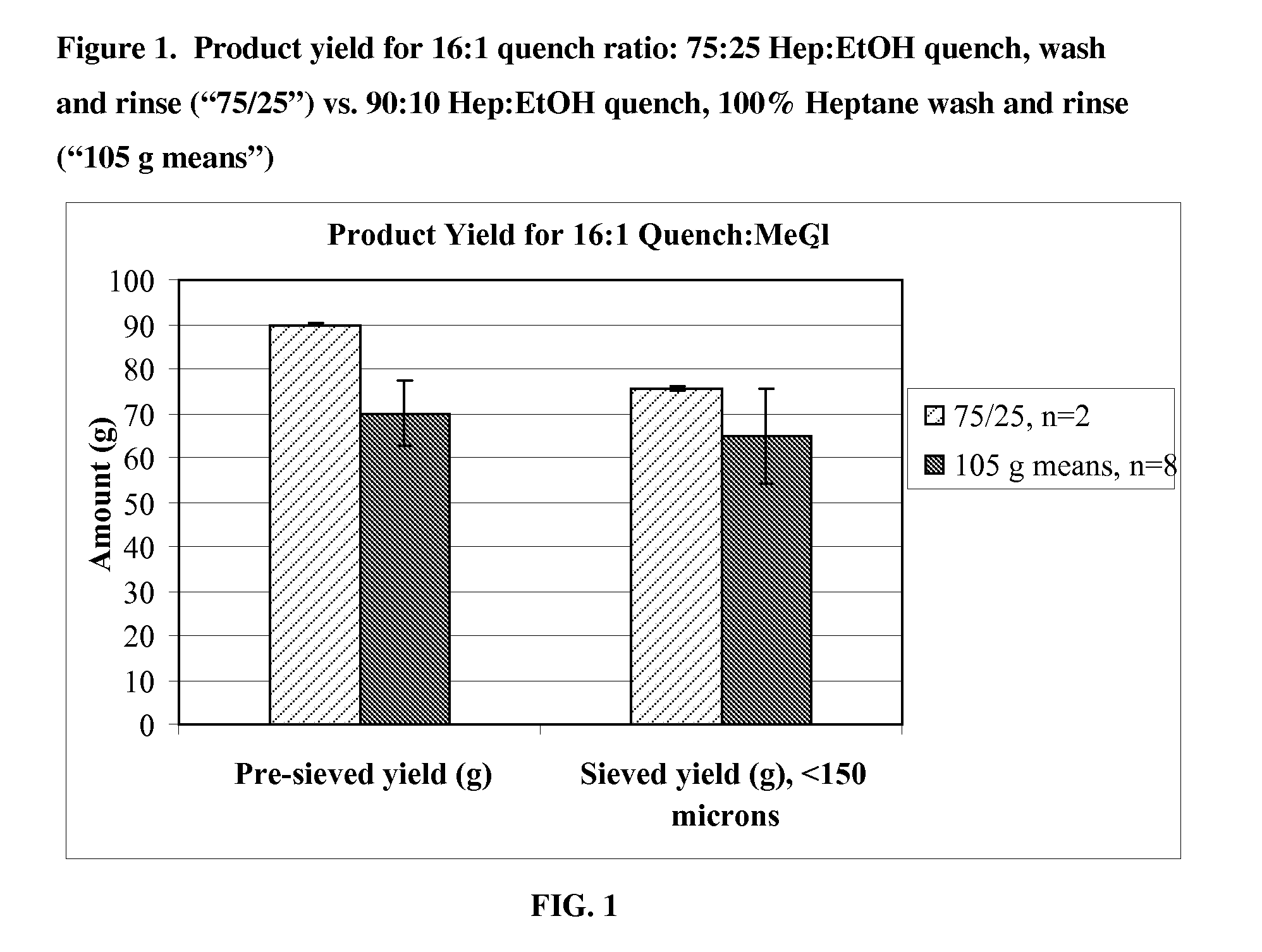

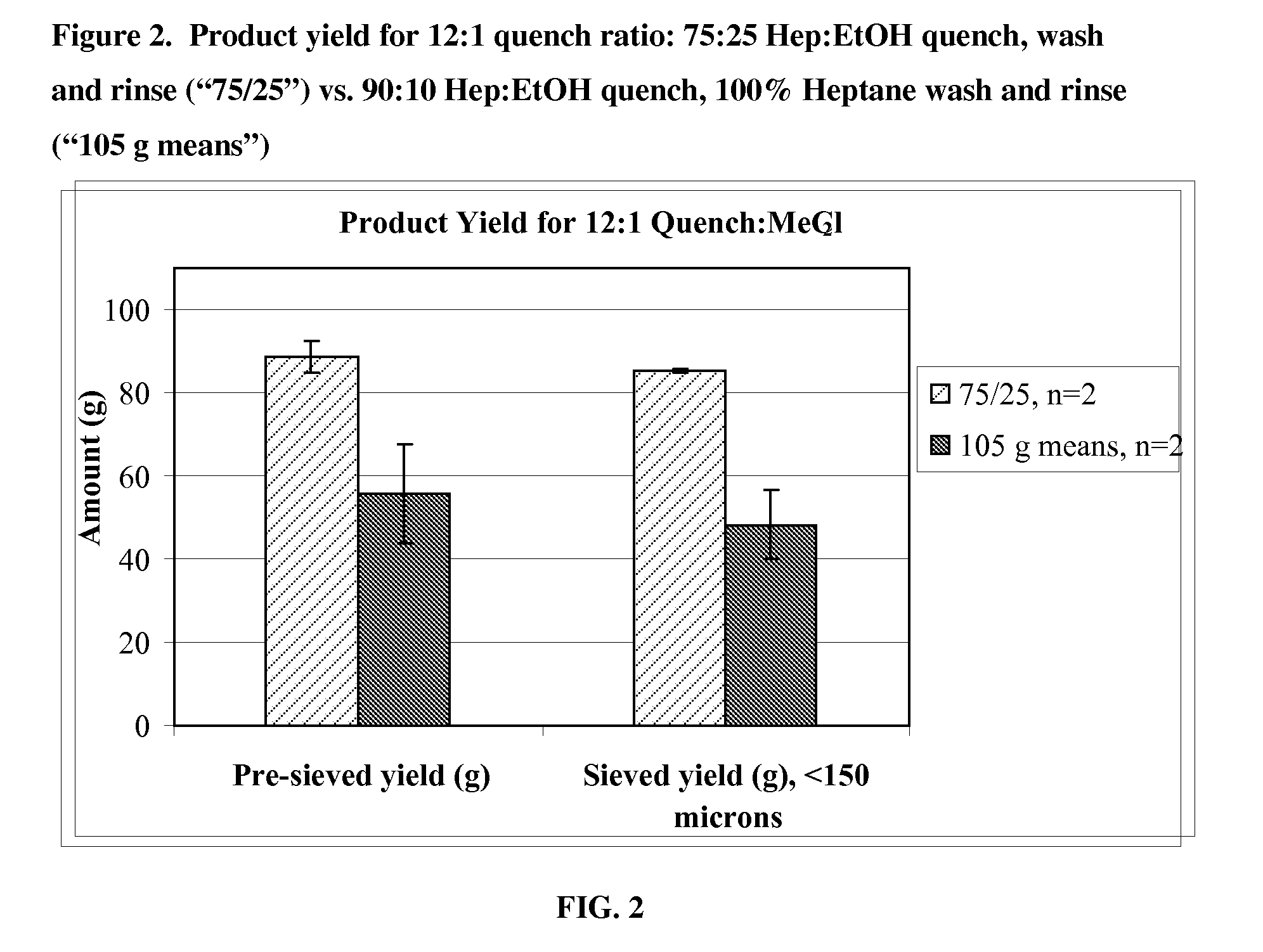

[0115]Microparticles were prepared using a large scale coacervation process. A 20 kg batch was produced using a 75:25 heptane-ethanol mixture for the quench, wash and rinse steps, and a quench liquid to methylene chloride ratio of 12:1. For comparison, four 15 kg reference batches were produced using a 90:10 heptane-ethanol mixture for the quench step, 100% heptane for wash and rinse steps, and a quench liquid to methylene chloride ratio of 16:1. The resulting microparticles were characterized with respect to yield, particle size, and residual solvents.

A. Inner Water-In-Oil Emulsion Formation

[0116]A water-in-oil emulsion was created with the aid of an in-line Megatron homogenizer MT-V 3-65 F / FF / FF, Kinematica AG, Switzerland. For the 20 kg batch, the water phase of the emulsion was prepared by dissolving 400 g sucrose in 12 kg water for irrigation (WFI). The oil phase of the emulsion was prepared by dissolving PLG polymer (e.g., 18,600 g of 50:50 DL4A PLG (Alkermes, Inc.)) in methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com