Mis gate structure type HEMT device and method of fabricating mis gate structure type HEMT device

a gate structure and gate structure technology, applied in the direction of semiconductor devices, basic electric elements, electrical apparatus, etc., can solve the problems of inability to achieve low on-resistance, inability to obtain low on-resistance, inability to ensure high two-dimensional electron gas concentration, etc., to achieve low access resistance and low on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Configuration of HEMT Device

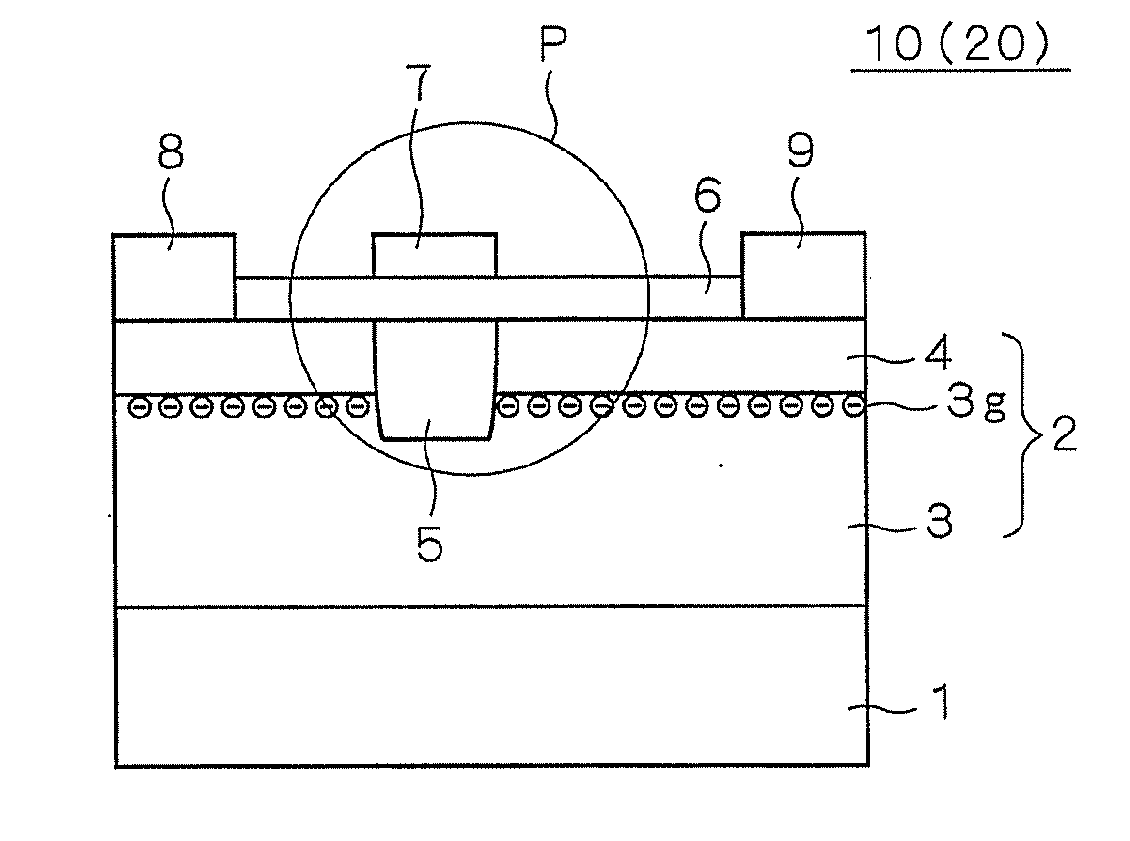

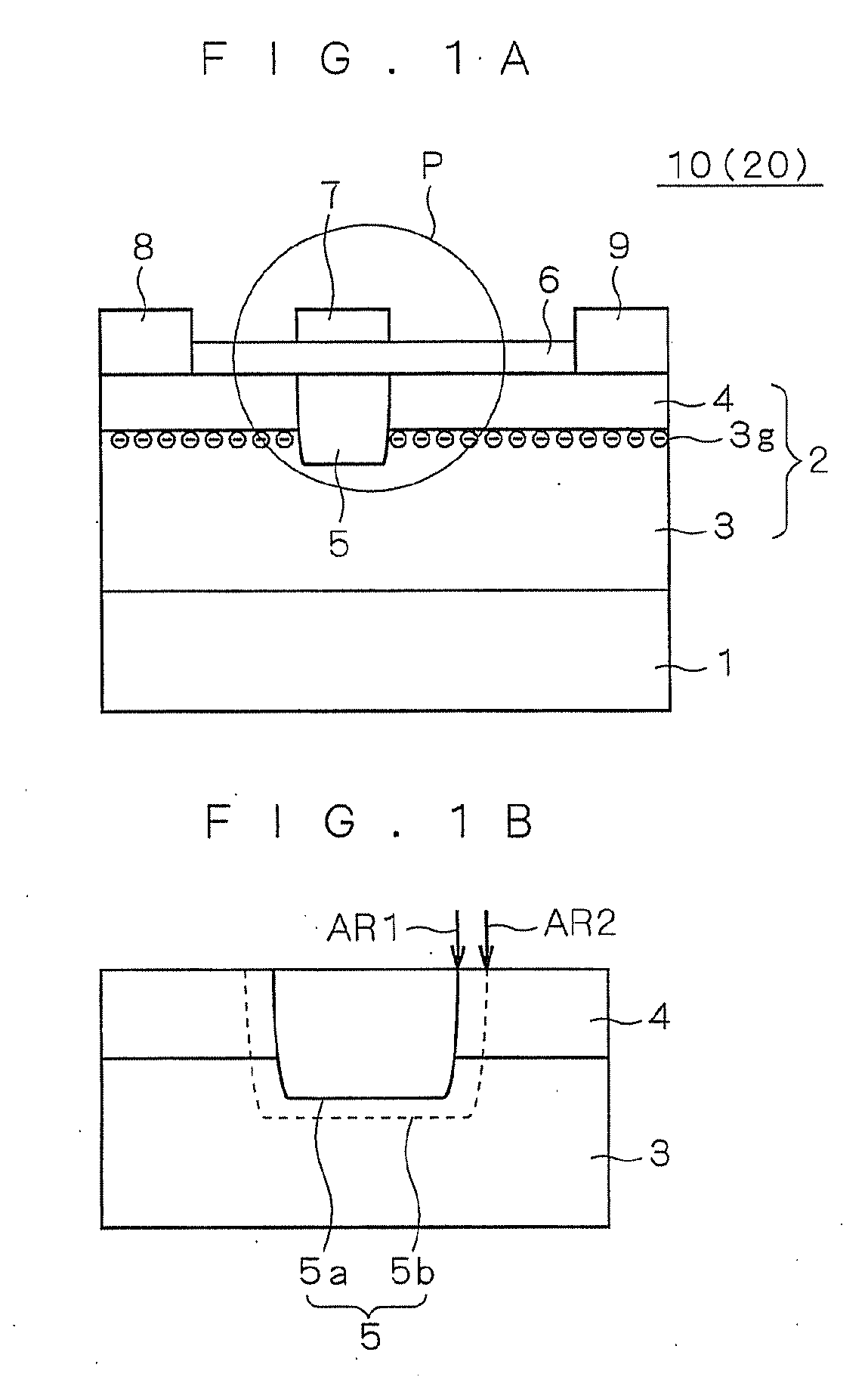

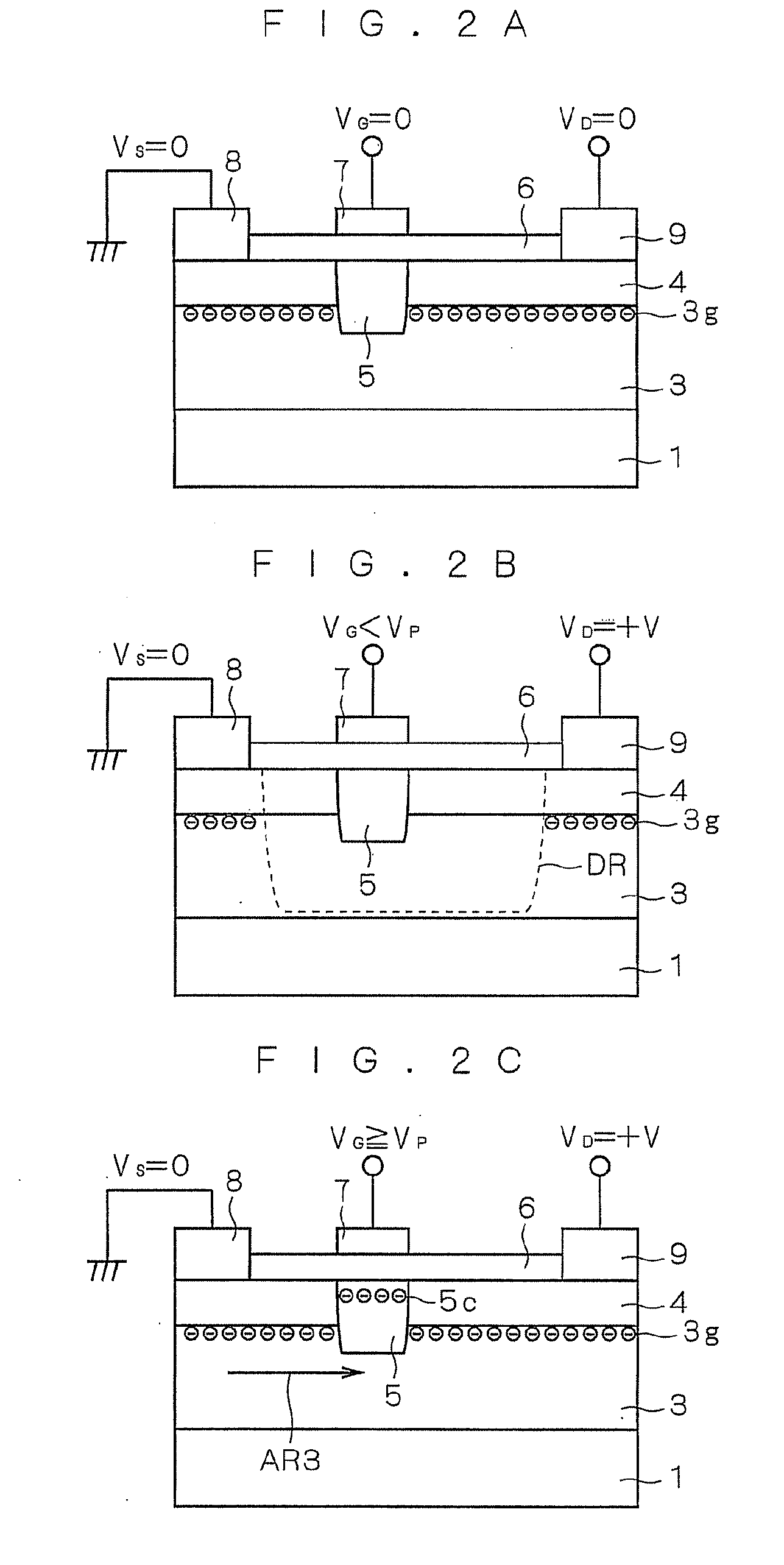

[0030]FIGS. 1A and 1B are views schematically showing a configuration of a HEMT device 10 according to a first embodiment. FIG. 1A is a typical cross-sectional view of an entire configuration of the HEMT device 10. As shown in FIG. 1A, from a schematic viewpoint, the HEMT device 10 according to the embodiment is provided with a semiconductor layer 2, an insulating layer 6, a gate electrode 7, a source electrode 8, and a drain electrode 9 on a substrate 1. That is, the HEMT device 10 has a MIS gate structure configured by forming the insulating layer 6 between the semiconductor layer 2 and the gate electrode 7. Further, the semiconductor layer 2 is provided with a base layer 3, a barrier layer 4, and a P-type region 5.

[0031]Use of a single crystal 6H—SiC substrate is one of preferable examples for the substrate 1, however, materials are not particularly limited as long as they can be used to form Group III nitride semiconductor layers such as the base laye...

second embodiment

[0072]In the first embodiment described above, an aspect in which the base layer 3 is formed as a high resistance layer having conductivity of N-type and a high specific resistance of 1×107 Ωcm or more are shown. However, the base layer 3 may be composed of Group III nitride having conductivity of P-type instead of this aspect. For example, the base layer 3 may be composed of GaN containing Mg as an acceptor. In this case, the layer is preferably formed in a manner that a hole concentration at room temperature is adjusted to be 1×1016 / cm3 to 1×1018 / cm3, for example, about 2×1016 / cm3.

[0073]Since such a HEMT device 20 has almost same configuration as that of the HEMT device 10 according to the first embodiment shown in FIG. 1A, the detailed description of the respective parts are omitted. However, the configuration of the P-type region 5 is slightly made different.

[0074]FIG. 4 is a view typically showing a configuration of a P-type region in the HEMT device 20. In the HEMT device 20, ...

third embodiment

[0079]FIG. 5 is a view schematically showing a configuration of a HEMT device 30 according to a third embodiment. In the present embodiment, the same symbols are assigned to the constituent components having the same functional effects as those of the constituent elements of the HEMT device 10 according to the first embodiment and detailed descriptions about the constituent components are omitted. Although the HEMT device 30 is same as the HEMT device 10 according to the first embodiment in a point that both have the MIS gate structure having the insulating layer 6 between the semiconductor layer 2 and the gate electrode 7, the HEMT device 30 differs in a point that an AlN layer (AlN spacer layer) 31 made of AlN is inserted between the base layer 3 and the barrier layer 4.

[0080]The AlN layer 31 is inserted for suppressing a decrease in an electron mobility due to partial immersion of the two-dimensional electron gas region 3g in the barrier layer 4. Accordingly, a further high mobil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com