Enhanced Hydrocarbon Recovery by in Situ Combustion of Oil Sand Formations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

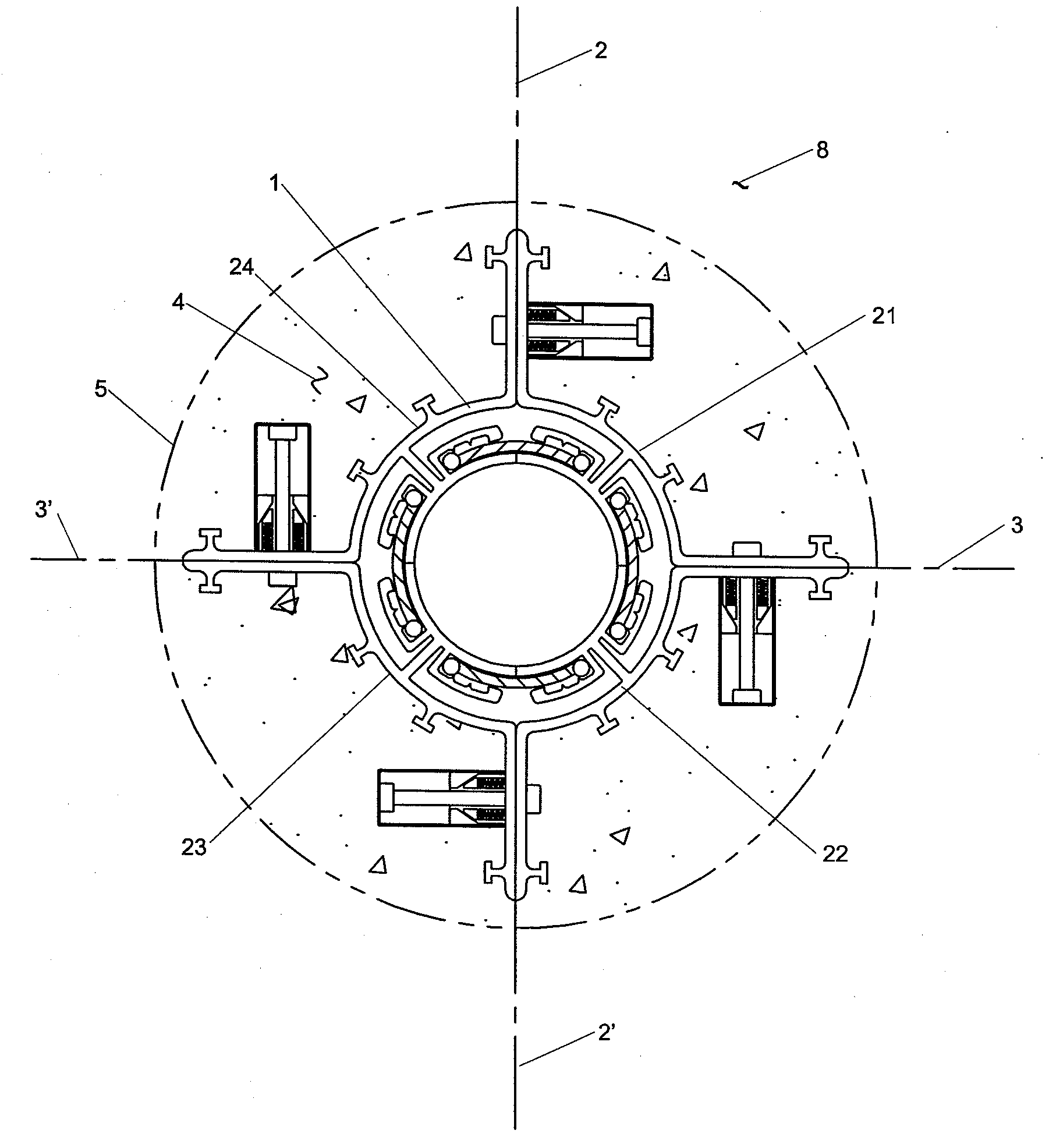

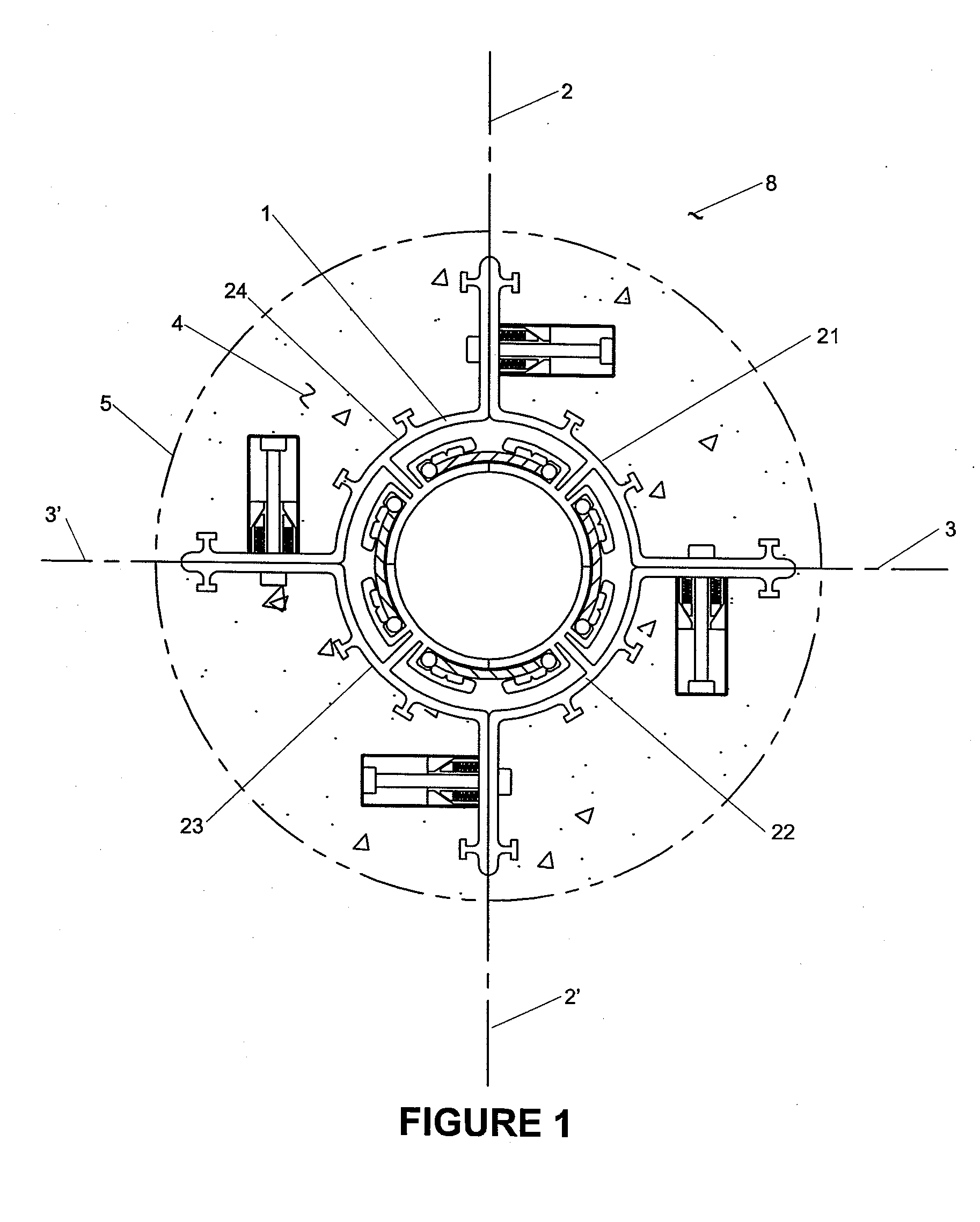

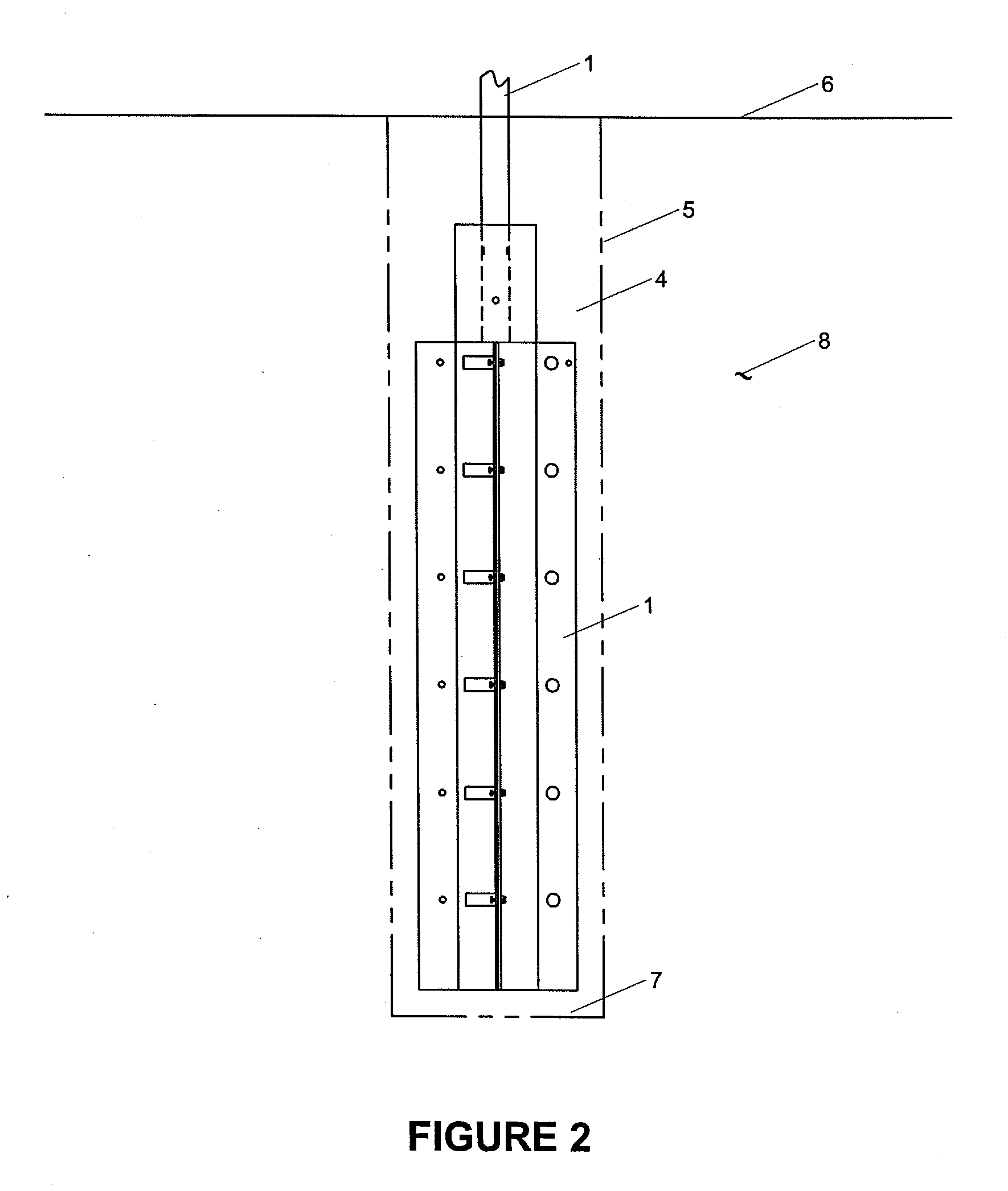

[0036]Several embodiments of the present invention are described below and illustrated in the accompanying drawings. The present invention is a method and apparatus for the enhanced recovery of petroleum fluids from the subsurface by in situ combustion of the hydrocarbon deposit, by injecting an oxygen rich gas, and by drawing off a flue gas to control the rate and progation of the predominantly horizontal combustion front to be vertically downwards. Multiple propped hydraulic fractures are constructed from the well bore into the oil sand formation and filled with a highly permeable proppant. The oxygen rich gas is injected via the well bore into the top of the propped fractures, the in situ hydrocarbons are ignited by a downhole burner, the generated flue gas is extracted from the bottom of the propped fractures through the well bore, and the mobile oil drains by gravity through the propped fractures to the bottom of the well bore and is pumped to the surface. The combustion front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com