Process for producing syndiotactic propylene polymer

a technology of syndiotactic propylene and polymer, which is applied in the direction of chemistry apparatus and processes, synthetic resin layered products, adhesive types, etc., can solve the problems of difficult to separate the copolymer, the molecular weight of the obtained copolymer is largely reduced, and the adhesion properties are inferior, etc., to achieve excellent adhesion properties, excellent thermal stability, and high graft ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

production example 1

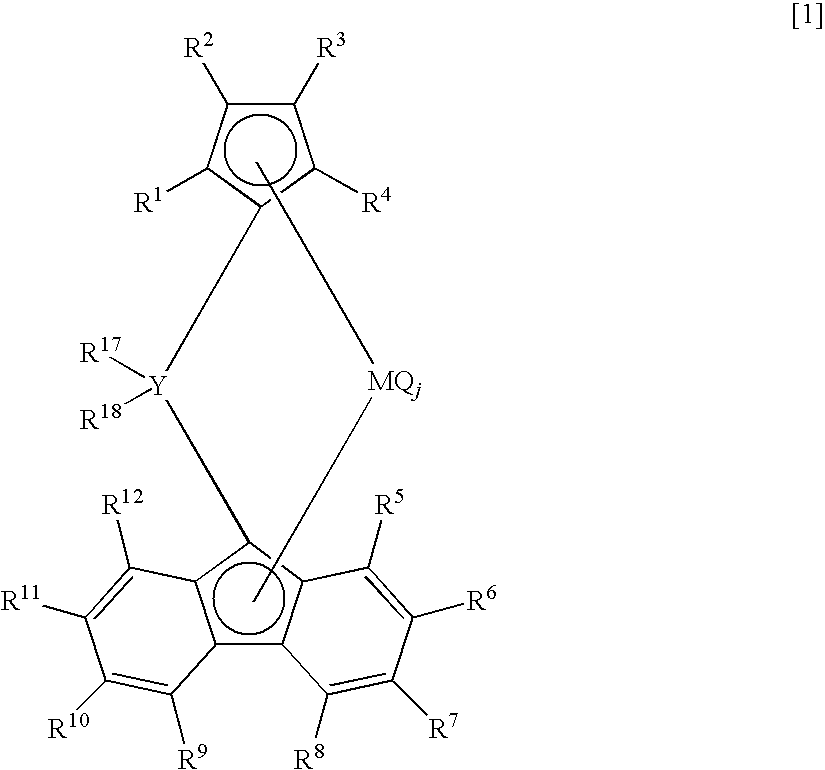

[0167]To a 3 m3 internal volume reaction vessel thoroughly purged with nitrogen, 1000 liters of n-heptane was introduced and 610 ml (0.93 mol) of a toluene solution (Al=1.53 mol / L) of methylaluminoxane was added dropwise at ordinary temperature. To a 5 liters internal volume side-arm flask thoroughly purged with nitrogen, a magnetic stirrer was put. To the flask, 610 ml (0.93 mol) of a toluene solution (Al=1.53 mol / liter) of methylaluminoxane, and then 1.30 g (1.86 mmol) of a toluene solution of

dibenzylmethylene(cyclopentadienyl)(2,7-diphenyl-3,6-ditert-butylfluorenyl) zirconium dichloride were added, and stirred for 20 min. The resulting solution was added to the reaction vessel, and 3200 NL of hydrogen was fed at a rate of 19 Nm3 / h over 10 min. Thereafter, the polymerization was started while feeding 65 Kg / h of propylene. While the hydrogen gas phase concentration in the reaction vessel was kept to 53 mol % and propylene was continuously fed in an amount of 65 Kg / h, the polymeriza...

example 1

[0168]100 parts by weight of the syndiotactic polypropylene prepared in Production Example 1 was dry blended with a solution prepared by dissolving 1.5 parts by weight of maleic anhydride (abbreviated to MAH, manufactured by Wako Pure Chemical Industries Ltd.), 1.5 parts by weight of t-butyl peroxy benzoate (Trade Name Perbutyl Z, manufactured by NOF Corporation) in acetone. Thereafter, melt modification was carried out using a twin axial kneader (KZW15, manufactured by Technovel Corporation) at a resin temperature of 180° C., at a screw rotation number of 200 rpm, and at an output rate of 25 g / min. In the extrusion, a radical initiator, a solvent, and unreacted maleic anhydride were deaerated in vacuo. After cooling, an extruded strand in a molten state was pelletized to prepare maleic acid-modified syndiotactic polypropylene (hereinafter abbreviated to MAH-sPP-1) having an rrrr fraction of 0.92, a graft amount of 1.30% by weight and MFR of 91 g / 10 min. The MAH-sPP had an internal ...

example 2

[0169]The procedure of the melt modification of Example 1 was repeated except for using 1.5 parts by weight of maleic anhydride and 1.5 parts by weight of t-butyl peroxy benzoate, and changing the resin temperature to 230° C. After cooling, an extruded strand in a molten state was pelletized to prepare maleic acid-modified syndiotactic polypropylene (hereinafter abbreviated to MAH-sPP-2) having a graft amount of 1.43% by weight and MFR of 392 g / 10 min. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tm | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

| Tm | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com