Optical compensation film, and polarizing plate and liquid crystal display employing the same

a technology of optical compensation film and liquid crystal display, which is applied in the direction of detergent compounding agent, instruments, other domestic articles, etc., can solve the problems of insufficient pasting ability, inability to provide function, and inability to stabilize wavelength dispersion characteristics, so as to improve visibility, reduce contrast, and improve visibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

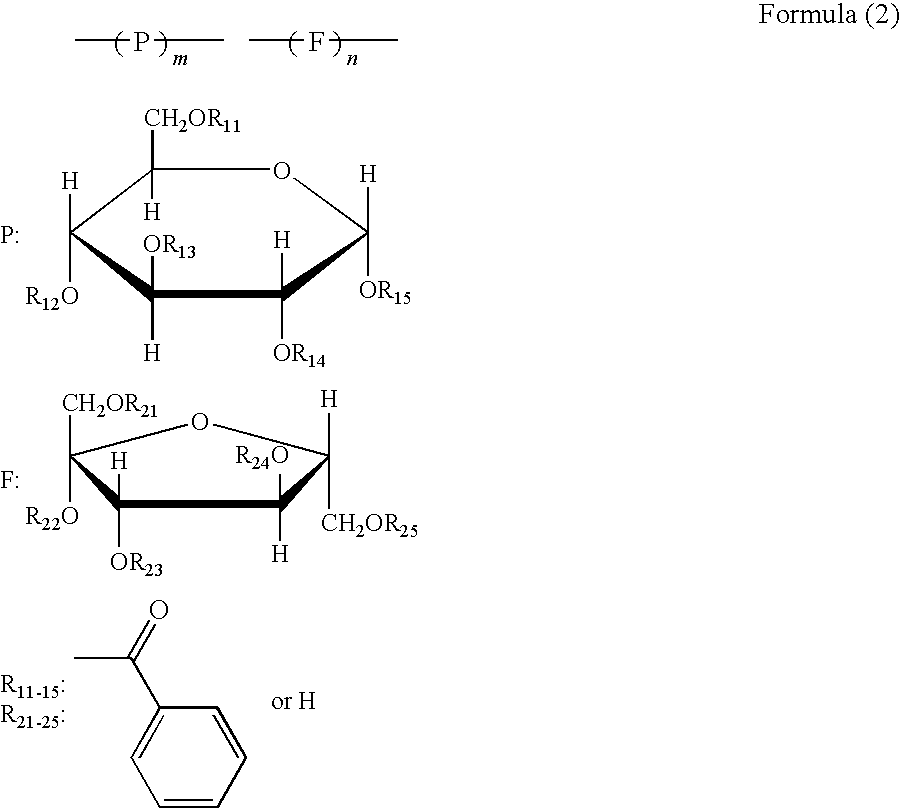

[0230]Cellulose ester, Polymer (a), a compound having a furanose or pyranose structure (Compound (b), sugar ester compound), plasticizers, and UV absorber used in the Examples are listed in Table 1.

TABLE 1Total substitu-Cellulosetion degree ofEsterSubstitution Degree of Acyl groupacyl groupAAcetyl group: 1.9Propionyl group: 0.82.7BAcetyl group: 1.6Propionyl group: 0.92.5CAcetyl group: 1.1Propionyl group: 0.92.0DAcetyl group: 1.2Propionyl group: 1.12.3EAcetyl group: 2.42.4FAcetyl group: 1.3Propionyl group: 1.22.5Sugar EsterCompoundAExemplified Compound 3BExemplified Compound 5CMixture of the same weight ofExemplified Compounds 6 and 7DExemplified Compound 8PlasticizerATriphenyl phosphateBEthylphthalyl ethylglycolateCTrimethylol propanetribenzoateUV AbsorberATINUVIN 326 Ciba Specialty ChemicalsBTINUVIN 109 Ciba Specialty ChemicalsCTINUVIN 171 Ciba Specialty Chemicals

[0231]Polymer (a) used in the Example is described below.

synthesis example 1

[0232]Copolymer AMP-6 of exemplified compound AM-2 and methylmethacrylate was synthesized in accordance the following method.

[0233]Hundred and twenty five grams of polymer raw material composed of 100 parts by weight of monomer mixture of 20% by weight of exemplified compound AM-2 and 80% by weight of methylmethacrylate to which 2.0 parts by weight of peroxy lauroyl, 0.25 parts by weight of n-octylmercaptan and 0.1 parts by weight of stearic alcohol were added, and 250 g of deionized water dissolving preliminarily 0.2 g of 1% aqueous solution of sodium polymethacrylate, 0.05 g of sodium dihydrogen phosphate and 0.15 g of disodium hydrogen phosphate were charged in a flask having stirrer, air was substituted with nitrogen, polymerization was carried out at 70° C. for 3 hours, and then polymerization was further carried out at 100° C. for 1 hour. Bead form of copolymer AMP-6 was obtained through cooling, filtration, washing and drying processes after completion of polymerization. The ...

synthesis example 2

[0235]Copolymer AMP-7 of exemplified compound AM-2 and methylacrylate was synthesized in accordance the following method.

[0236]Into 100 ml of toluene, 10 g of monomer mixture of 50 weight parts of AM-2 and 50 weight parts of methyl methacrylate was added, then 0.1 g of azobisisobutyronitrile was added. Temperature was raised up to 80° C. and polymerization was carried out for 5 hours in nitrogen atmosphere. After removing 70 ml of toluene by evaporation under reduce pressure, the content was dripped far excess amount of methanol. Deposited precipitation was subjected to filtration, washing, and drying processes, and powder copolymer AMP-7 was obtained. The copolymer was confirmed to have an weight average molecular weight of 30,000 and Mw / Mn of 3.0 by GPC analysis employing standard polystyrene.

[0237]Thus obtained copolymer was confirmed as a copolymer of the exemplified compound AM-2 and methylacrylate by NMR spectrum. Composition content of AM-2 / methylacrylate was approximately 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com