Production of moldable bone substitute

a bone substitute and moldable technology, applied in the field of composites, can solve the problems of insufficient standard bone fracture treatment, damage to bone tissue, and inability of the body to heal by itself, and achieve the effects of controlling the hardening speed of the composite, long shapeability time, and high final strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of Nanocrystalline Hydroxyapatite Gel

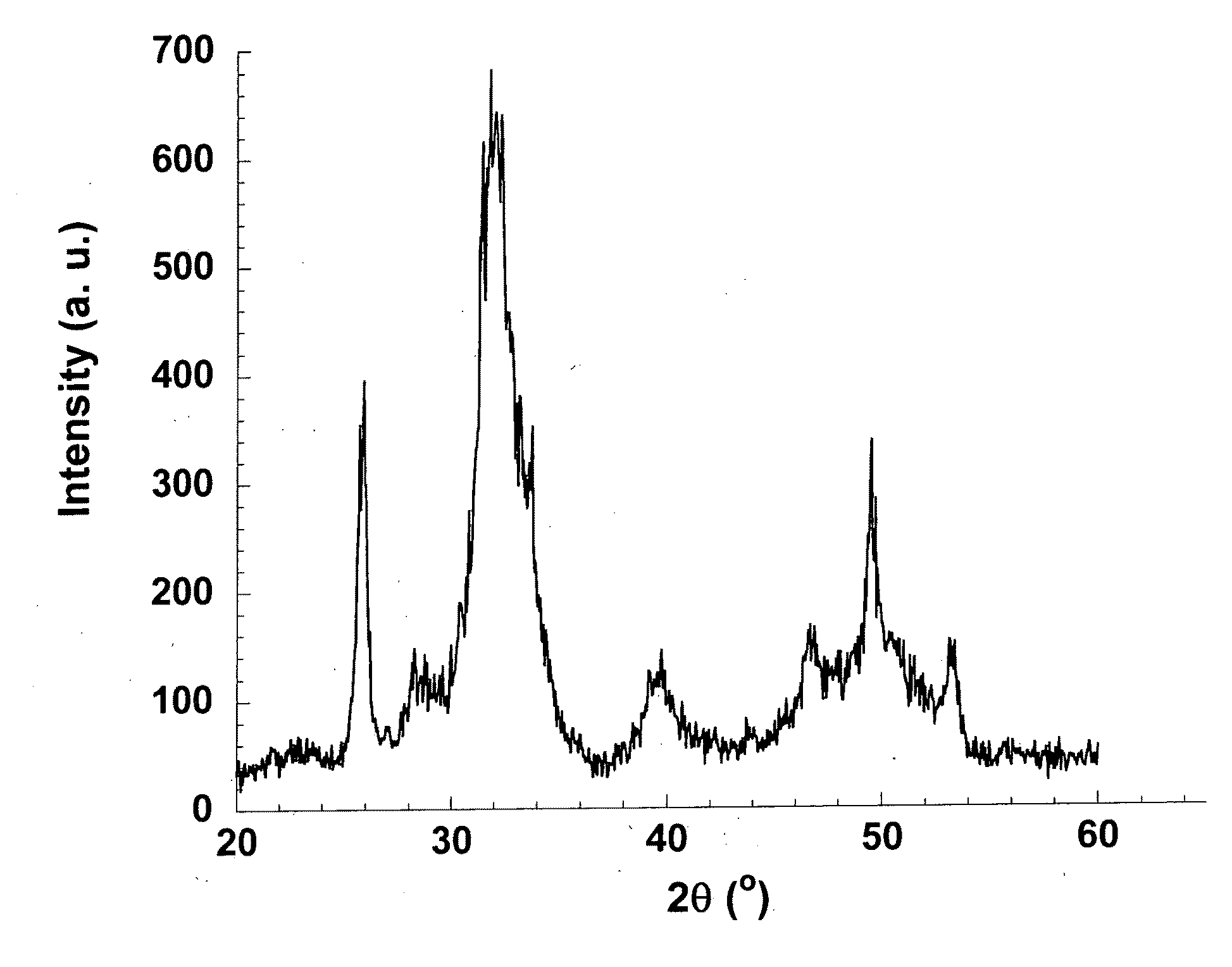

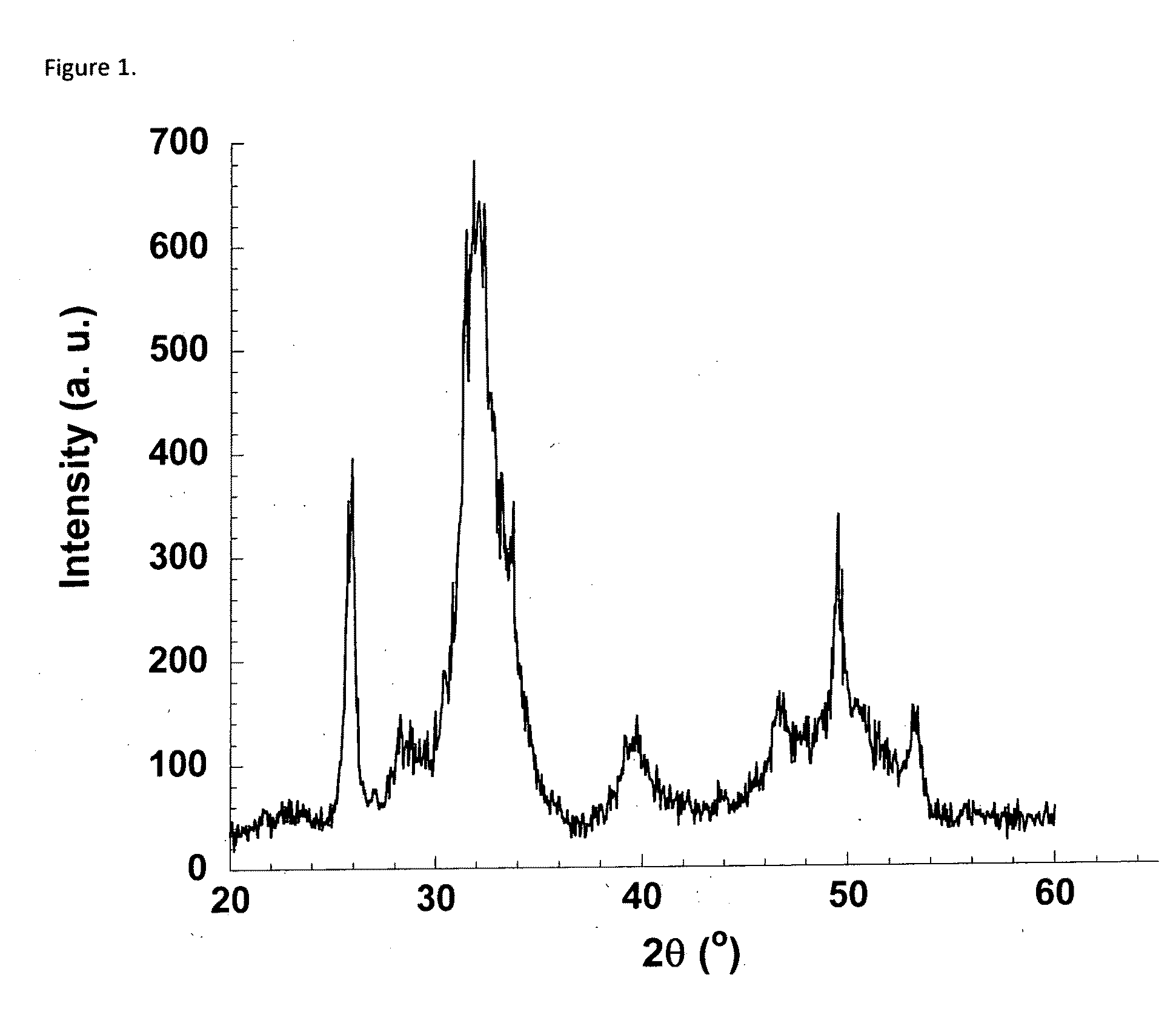

[0069]2.82 g of CaO was mixed with 150 ml of H2O in a beaker. The dispersion was allowed to stir for 1 hour. In a separate beaker, 3.45 g of H3PO4 (85 wt %) was mixed with 150 ml of H2O. The contents in the two beakers were mixed at ambient temperature, and the resulting gel was allowed to stir for 12 hours. The mixture was filtered in a grade 4 glass filter and washed extensively with water (2.5 L). A portion of the gel was dried and analyzed with XRD and nitrogen adsorption. The specific surface area, as calculated with the BET method, of this sample was found to be 200 m2 / g.

example 2

Synthesis of Nanocrystalline Hydroxyapatite Gel with Amino Acids

[0070]The nanocrystalline hydroxyapatite was prepared as follows. 6.70 g of L-Aspartic acid was mixed with 150 ml H2O in a beaker. 2.82 g of CaO was added to this solution, and the mixture was allowed to stir for 1 hour. In a separate beaker, 3.45 g H3PO4 (85 wt %), 6.65 g L-Lysine and 150 ml H2O was mixed. The pH of this solution was 6.46. The contents in the two beakers were mixed at ambient temperature, and the pH was measured to 8.10. The mixture was allowed to stir for 12 hours. The mixture was filtered in a grade 4 glass filter and washed extensively with water (2.5 L) to remove excess amino acids. The pH of the resulting gel was measured to 7.90.

[0071]A portion of the gel was dried and analyzed with XRD and nitrogen adsorption. The X-ray diffractogram is shown in FIG. 1. The specific surface area, as calculated with the BET method, of this sample was found to be 210 m2 / g.

example 3

PCL / Tocopherol / HA

[0072]HA gel was prepared according to Example 1 or 2. The gel, consisting of coated hydroxyapatite particles and water, was mixed with 6 grams of poly(caprolactone) with a molecular weight of 80000 g / mol, and 6 grams of tocopherol. The mixture was heated to 70° C. under extensive stirring until complete evaporation of the water had occurred. The yellow colored mixture was removed from the stirring equipment and allowed to cool to room temperature. The composite was readily moldable for approximately 45 minutes, during which the compressive strength was found to be below 4 MPa. The maximum compressive strength of 6.7 MPa was reached after roughly 120 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nanoscale particle size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com