Ultra-High Strength, Corrosion Resistant Wire, a Method of Making Same, and a Method of Using Same

a high-strength, corrosion-resistant wire technology, applied in the direction of layered products, transportation and packaging, chemical instruments and processes, etc., can solve the problems of alloy lack of ductility to resist breaking in a standard wire-wrap test, and users of such cables are now demanding even higher strength levels for this application, so as to reduce the cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working examples

Example 1

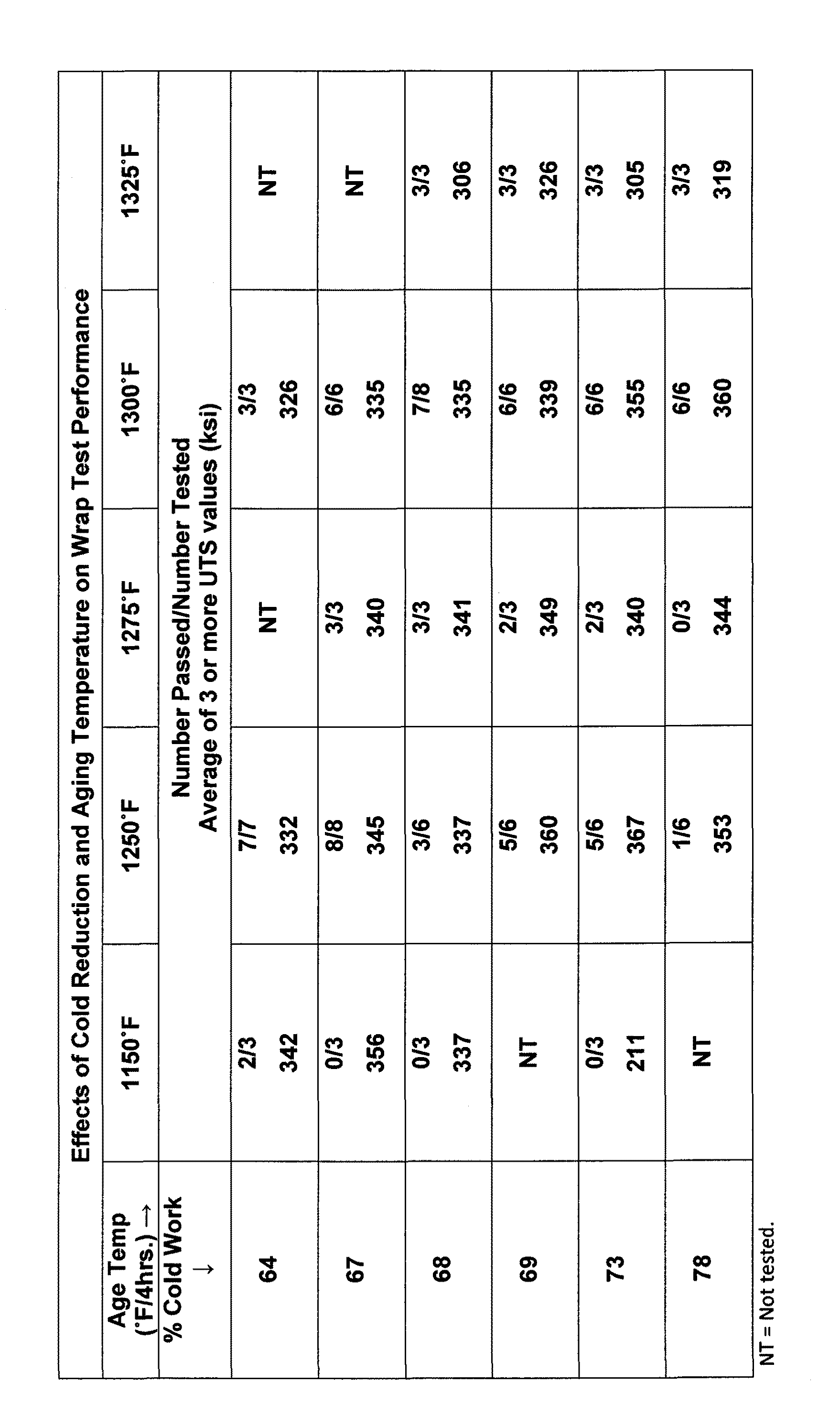

[0015]Experimental trials were performed using 0.0565 in rd. wire from a triple melted heat having the weight percent composition set forth in Table I below. Triple melting is a known technique that includes the steps of vacuum induction melting (VIM), followed by electroslag remelting (ESR), and then vacuum arc remelting (VAR). The wire was annealed at subatmospheric pressure at 1800° F. for 90 minutes and then quenched in argon gas. The grain size of the annealed wire was about ASTM size 6-8. Wire samples cut from the annealed coils were cold drawn to 50%, 55%, 60%, 64%, and 67% reductions in cross-sectional area (R.C.S.A.) to provide wire diameters of 0.040 in., 0.038 in., 0.036 in., 0.034 in., and 0.032 in., respectively. Cold drawing is performed with the wire at room (ambient) temperature. The wire samples were then aged at temperatures in the range of 1050° F.-1250° F. in argon-filled SEN / PAK® heat treating containers. Fine wire tensile tests and wrap tests were cond...

example 2

[0019]In a second set of tests, wire from another production heat of the UNS R00035 alloy was processed into fine wire. The heat chemistry of the additional wire material (Example 2) is presented in Table I above. The wire was cold drawn 68% R.C.S.A. to 0.031″ in diameter. The cold drawn wire was aged at various combinations of temperature and time as shown in Table V. Also, set forth in Table V are the results of room temperature tensile and wrap tests including the 0.2% offset yield strength (0.2% Y.S.) and the ultimate tensile strength (U.T.S.) in ksi, the percent elongation (% El.), the percent reduction in area (% R.A.), together with an indication whether the wire passed or failed the wrap test (Wrap Test). The aging heat treatment given to each test sample is shown in the column labeled “Age Treatment”. Some of the wire samples were given underaging heat treatments at 600° F. and 750° F., respectively, for 4 hours. The underaged samples were evaluated to determine if the desi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com