Film of n type (100) oriented single crystal diamond semiconductor doped with phosphorous atoms, and a method of producing the same

a technology of phosphorous atoms and n-type atoms, which is applied in the direction of polycrystalline material growth, crystal growth process, transportation and packaging, etc., can solve the problems of n-type atoms added to the amount of n-type atoms, the crystallinity of the fabricated is not affected, and the film of n-type (100) oriented single crystal diamond semiconductor cannot be obtained, etc., to achieve the effect of large impact in the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

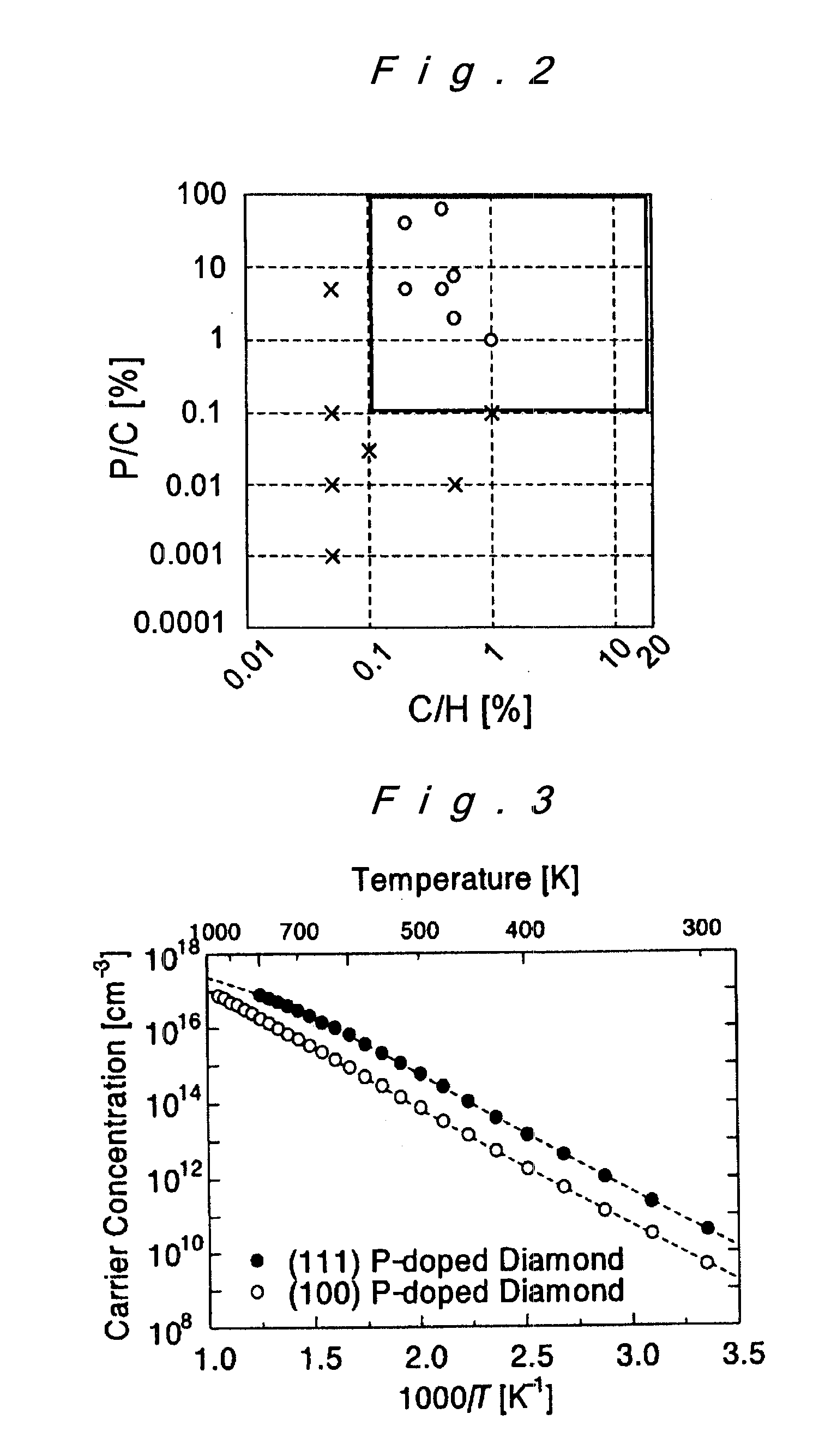

[0038]In accordance with a microwave plasma chemical vapor phase synthesizing method, phosphine was added to hydrogen containing 0.2% of methane so that the ratio of phosphorous (P) to carbon (C) became 5% and the resulting gas was introduced into a reaction chamber having a pressure for synthesis of 50 Torr, and a diamond film was formed on the (100) oriented single crystal diamond having an off angle of 1.5 degrees (a diamond substrate where the plane direction is inclined by 1.5 degrees in any direction for the (100) plane), on the substrate at 900° C. The film was confirmed to have n type properties at room temperature by measuring the Hall effect, and the mobility thereof was 350 cm2 / Vs and the concentration of the carrier was 3×109 cm−3.

example 2

[0039]In accordance with a microwave plasma chemical vapor phase synthesizing method, phosphine was added to hydrogen containing 0.5% of methane so that the ratio of phosphorous (P) to carbon (C) became 7.5% and the resulting gas was introduced into a reaction chamber kept at a pressure for synthesis of 75 Torr, and a diamond film was formed on the (100) oriented single crystal diamond having an off angle of 2.8 degrees, at 800° C. on the substrate. The film was confirmed to have n type properties at room temperature by measuring the Hall effect, and the mobility thereof was 47 cm2 / Vs and the concentration of the carrier was 9×109 cm−3.

example 3

[0040]In accordance with a microwave plasma chemical vapor phase synthesizing method, phosphine was added to hydrogen containing 0.4% of methane so that the ratio of phosphorous (P) to carbon (C) became 5% and the resulting gas was introduced into a reaction chamber kept at a pressure for synthesis of 25 Torr, and a diamond film was formed on the (100) oriented single crystal diamond having an off angle of 0.5 degrees at 900° C. of the substrate. The film was confirmed to have n type properties at room temperature by measuring the Hall effect, and the mobility thereof was 230 cm2 / Vs and the concentration of the carrier was 5×109 cm−3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| off-angle | aaaaa | aaaaa |

| off angle | aaaaa | aaaaa |

| off angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com