Dehydration of liquid fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

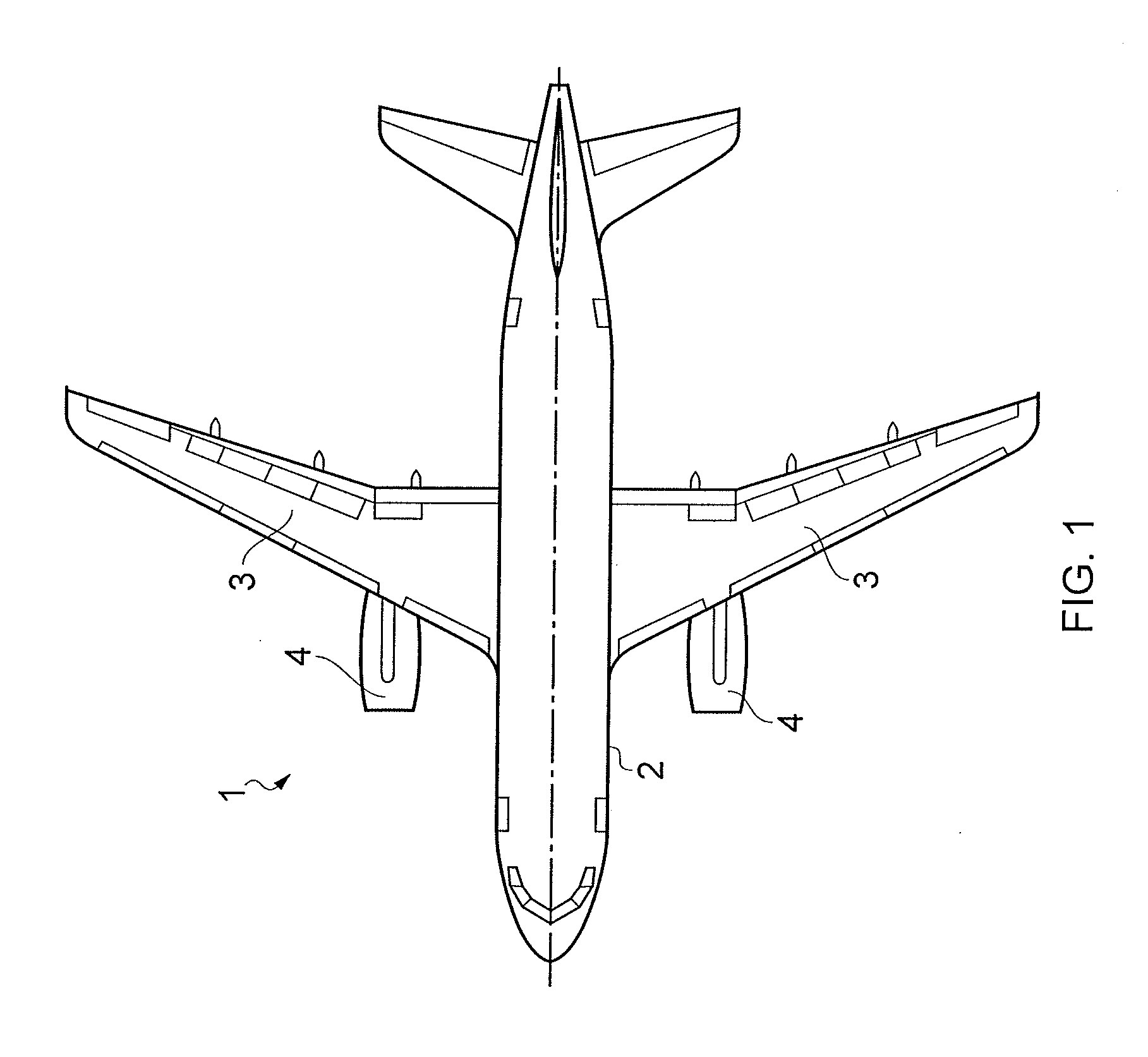

[0032]FIG. 1 illustrates a plan view of an aircraft 1, such as a commercial airliner, comprising a fuselage 2, a wing 3 and under wing mounted engines 4. The interior volume of the wing 3 is used as fuel tanks for storing liquid hydrocarbon aviation fuel, such as Jet A-1. The aircraft 1 has a three tank configuration, which forms part of an aircraft fuel system.

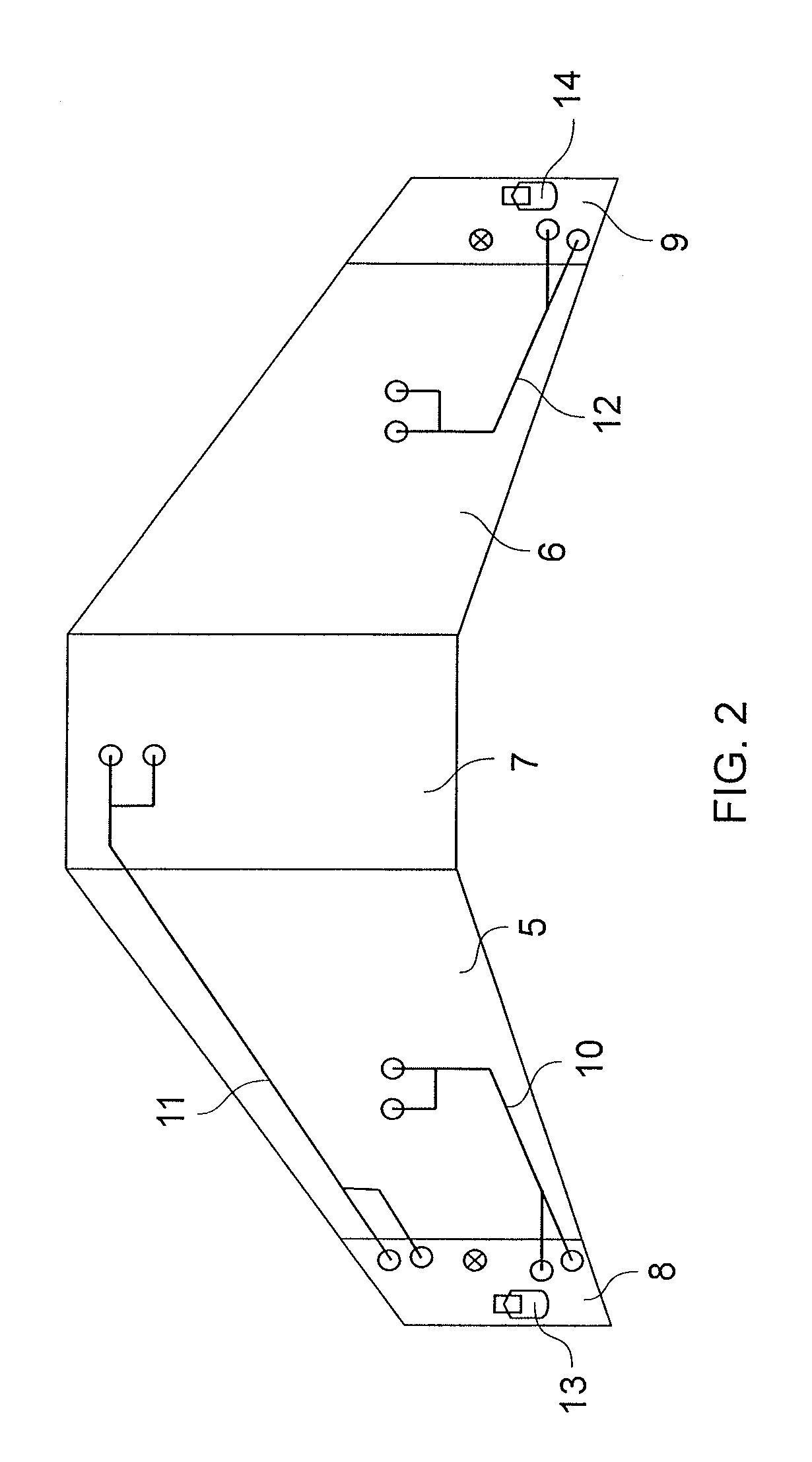

[0033]FIG. 2 illustrates schematically the three tank configuration which comprises a left wing tank 5, a right wing tank 6 and a centre tank 7. The aircraft fuel system further comprises a ventilation system for ventilating the ullage of each of the fuel tanks 5, 6, 7. The ventilation system includes a left vent tank 8 and a right vent tank 9 disposed at the tips of the wing 3. The vent tank 8 ventilates the left wing tank 5 by means of ventilation pipe 10, and also ventilates the centre tank 7 by means of ventilation pipe 11. The right vent tank 9 ventilates the right wing tank 6 by means of ventilation pipe 12. Each vent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com