Apparatus and method for increasing spin relaxation times for alkali atoms in alkali vapor cells

a technology of alkali vapor cells and spin relaxation times, applied in the field ofatomic vapor cells, can solve the problems of increasingaffecting the sensitivity of atomic vapor cell devices, and causing undesirable broadening of optical transitions, etc., to achieve the effect of reducing the relaxation rate of polarized vapor atoms, and improving the sensitivity o

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0054]In order to demonstrate the longevity of Zeeman populations and coherences in alkali-metal vapor cells with inner walls coated with an alkene material, a room temperature magnetometer with cells coated with 1-nonadecene (CH2—CH(CH2)16—CH2) was used in the context of spin-exchange relaxation-free (SERF) magnetometry, a regime inaccessible with conventional paraffin coating materials. Coherences in excess of 60 seconds were observed with 3 cm diameter cells corresponding to approximately 1,000,000 polarization-preserving alkali-wall collisions. This represents approximately 2 orders of magnitude improvement over the best paraffin coatings.

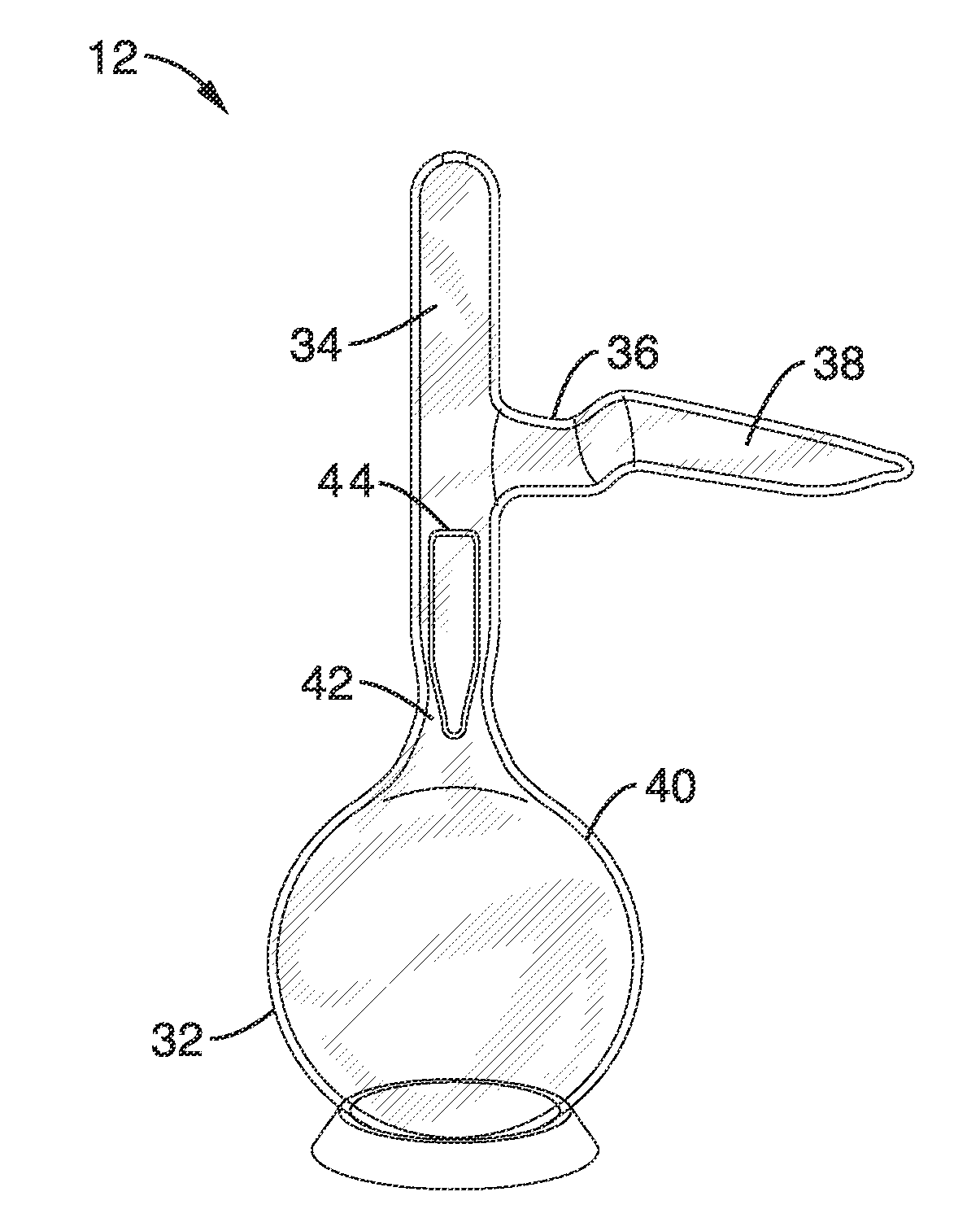

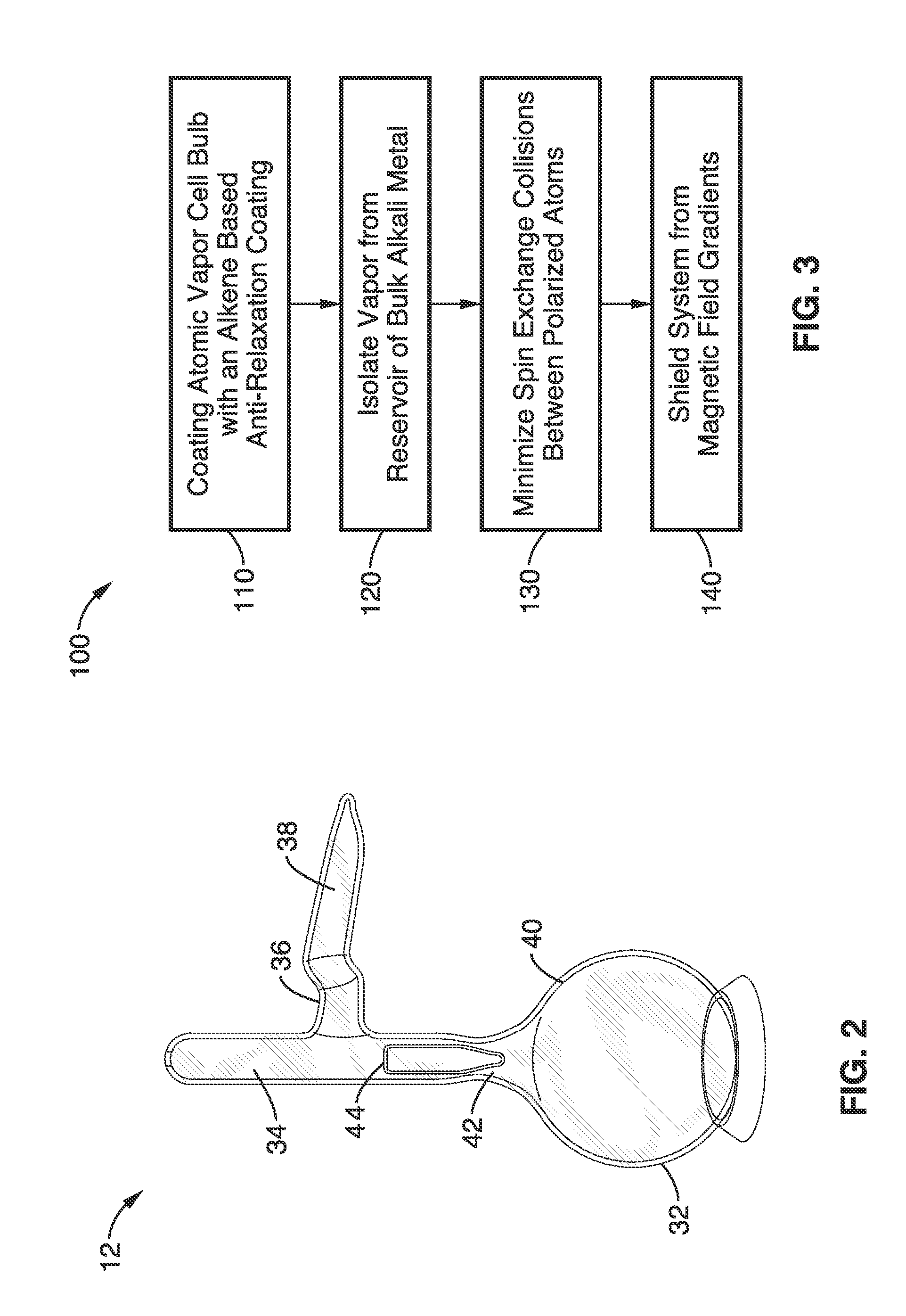

[0055]Since the exchange of atoms between the bulb of the cell and the stem with the Rb reservoir can produce rapid relaxation, a “lockable stem” was employed that provided a coated barrier to reduce the rate of exchange between the vapor in the bulb and the stem as shown in FIG. 2. To investigate the alkene-based coating carefully, three Rb va...

example 2

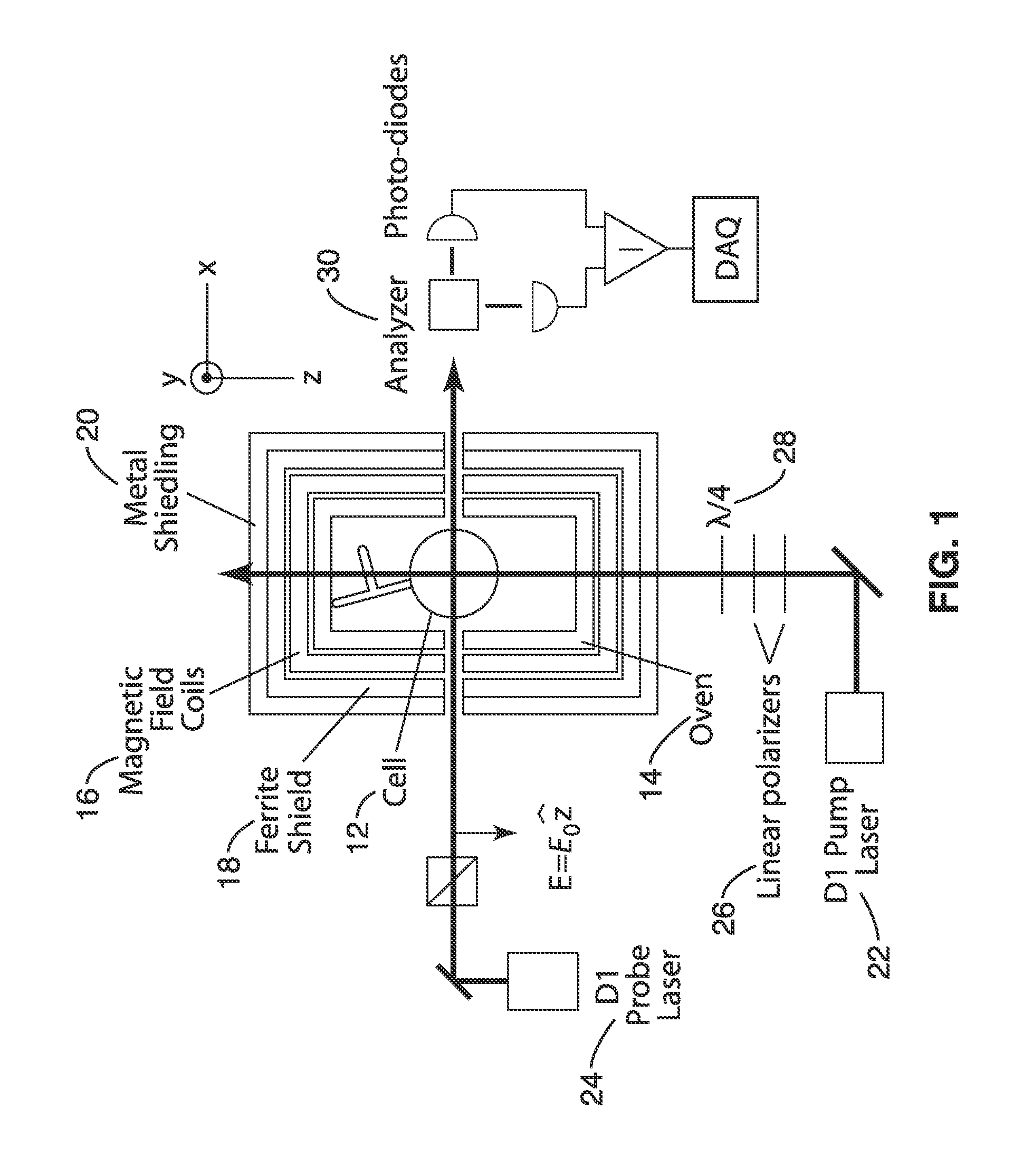

[0064]To further illustrate the method for achieving long spin relaxation times in an alkene coated atomic vapor cell, numerical calculations were performed for comparison with experimental results from the apparatus that was constructed according the general schematic shown in FIG. 1. In order to compare the experimental results with the theoretical calculations it was convenient to plot the measured spin-exchange broadening ASE as a function of the effective gyromagnetic ratio γ, shown as triangles in FIG. 5. It can be seen that there is a linear relationship between the spin-exchange broadening and effective gyromagnetic ratio parameters, as indicated by the linear fit overlaying the data. It is also worth noting that, in these measurements, spin-exchange broadening approaches an asymptotic value of about 0.2 s−1 / μG2 at high power due to the presence of two isotopes, as can be seen by the clustering of data points at high light power, despite the increasing size of the light powe...

example 3

[0068]To demonstrate the adaptability and versatility of the coated atomic vapor cell for use in different types of magnetometry, a magnetometer was constructed for nonlinear magneto-optical rotation (FM-NMOR) magnetometry for evaluation. A typical NMOR apparatus includes an atomic vapor cell and two lasers, one for pumping the optical transitions of the atomic vapor of an alkali metal, in this case rubidium, and the other for probing the optical vapor, by differential polarimetry to detect the rotation of polarization. Electronics amplify the differential polarization signal and filter out noise, then condition the phase and amplitude for feedback to the pump laser. With the proper feedback, the magnetometer self-oscillates at a frequency that is a multiple of the Larmor frequency (or its harmonics). Counting the oscillation frequency over some period of time provides an estimate of the average magnetic field during that time. To enhance sensitivity, the atomic sample is held in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com