Dairy product and process

a technology of whey protein and product, which is applied in the field of making whey protein concentrate, can solve the problems of denatured whey protein, high price, and undesirable gelling properties, and achieve the effect of simple heating step and without producing undesirable textures or flavours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0107]Fresh cheese whey was prepared using standard commercial ultrafiltration / diafiltration techniques to produce a retentate of about 20% total solids, of which 83% was protein. This concentrate stream was then adjusted to pH 6.9 using dilute NaOH and then further concentrated to about 33% solids using a falling film evaporator to produce a concentrate with an exit temperature of 45° C.

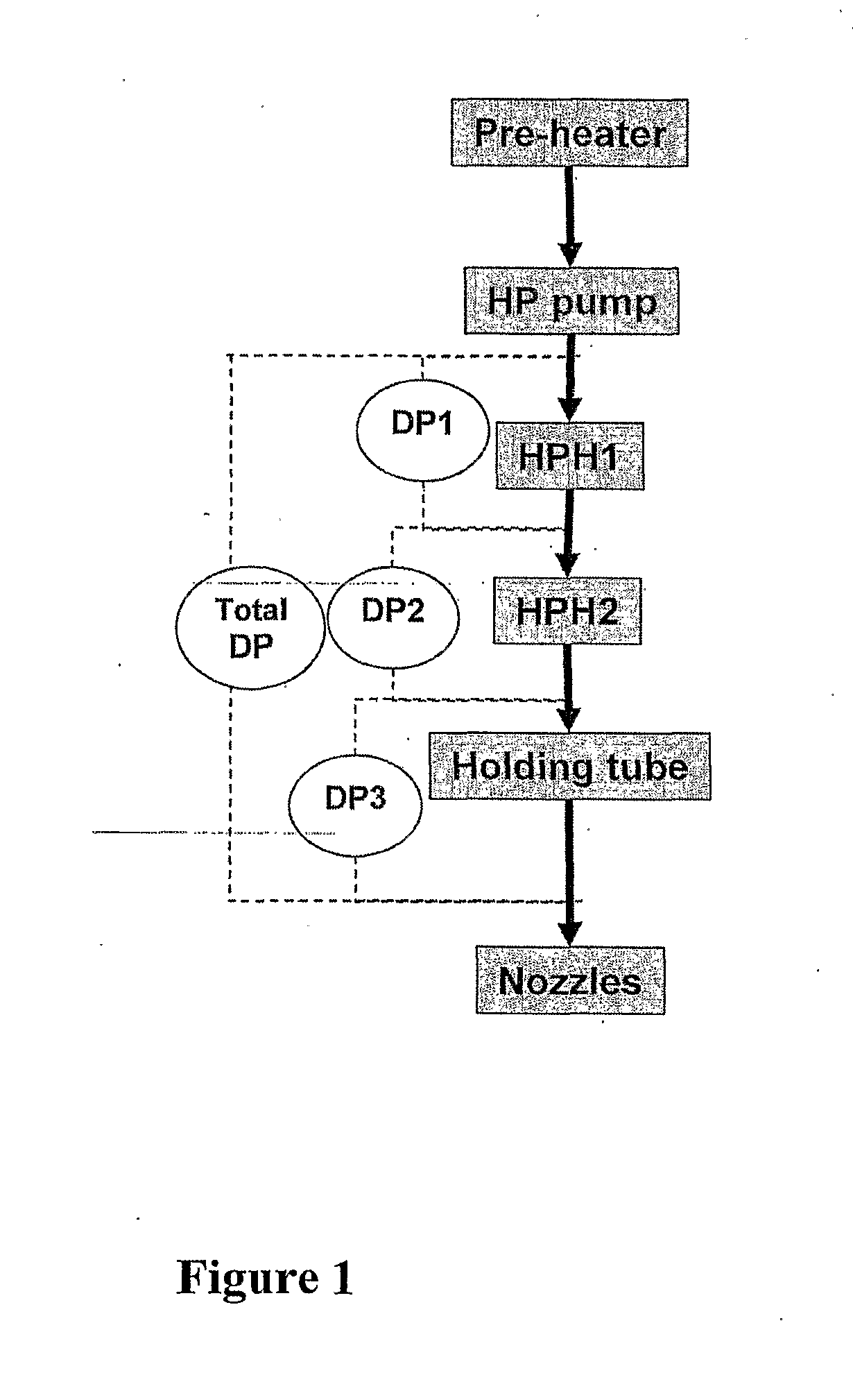

[0108]The warm concentrate (27% w / w protein) was fed at a flow rate of 6.3 m3 / h to two high pressure steam heated shell and tube heat exchangers in series using a high pressure pump with a delivery pressure of 250-300 bar. The concentrate exits the first high pressure heater (length 60 m) at ˜70° C. and exits the second high pressure heater at 80° C. The heater exchangers have a combined length of 120 in with an internal pipe diameter of 18.85 mm. The steam pressure supplied to the first heater was 0.6 bar (g) and the second heater pressure was 0.96 bar (g). The high pressure tubing was Schedule 80 ...

example 2

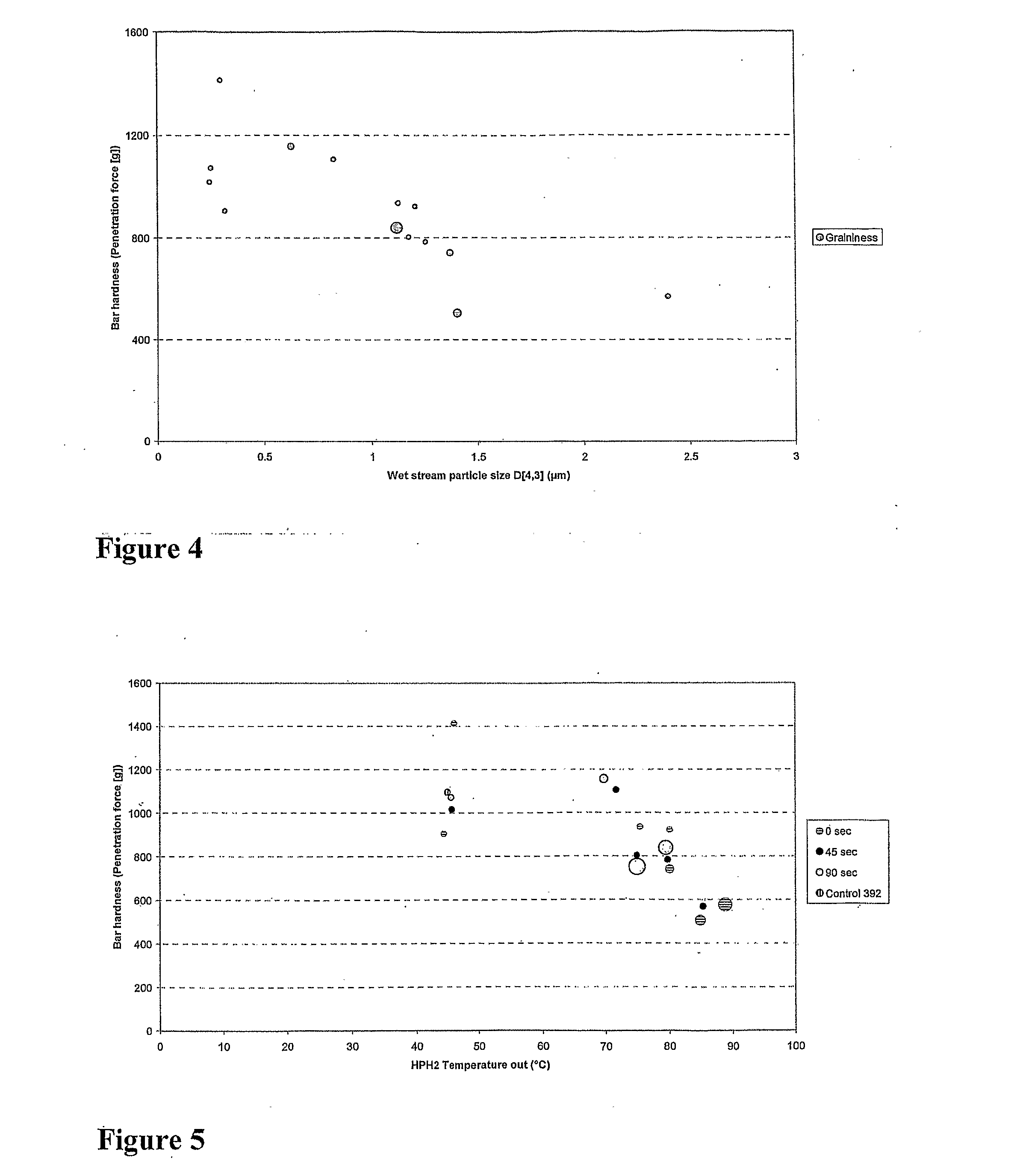

[0126]The inventive protein ingredient Was prepared using the method previously disclosed using a whey protein feed stream containing approximately 80% protein on a solids basis and a solids concentration of 32%, a processing flow rate of 6.4 m3 / h, a high pressure preheater outlet temperature of 58° C., a final high pressure heater outlet temperature of 80° C. and a residence time from the heater exit to the dryer of 23 seconds i.e. 0 s holding tube plant configuration.

[0127]Trials were carried out to establish the texture and sensory properties of high protein yoghurt using either the inventive heat denatured whey protein ingredient or a commercial native cheese whey WPC392 (Fonterra Co-operative Group Limited, Auckland, New Zealand) as alternative sources of protein fortification. These yoghurts will be compared to a standard 4.5% protein yoghurt (3.5% protein from skim milk, 1.0% protein from SMP top-up).

[0128]Initial yoghurt trials were carried out using the ingredient of this i...

example

High Protein Drinking Yoghurt with Low Viscosity

[0146]The inventive protein ingredient was prepared using the method of Example 1 using a whey protein feed stream containing approximately 80% protein on a solids basis and a solids concentration of 32%, a processing flow rate of 6.4 m3 / h, a high pressure preheater outlet temperature of 58° C., a final high pressure heater outlet temperature of 80° C. and a residence time from the heater exit to the dryer of 23 seconds i.e. 0 s holding tube plant configuration.

[0147]Trials were carried out to manufacture high protein drinking yoghurt with viscosity low enough for the final product to be consumed as a beverage.

[0148]Experimental Plan / Variables

[0149]Formulations

[0150]The recipes are given in Table 1.

TABLE 5Recipes for the preparation of the fermented beverageQuantity (g)High protein4.5% low fatInventiveyoghurtComponentbeverage(control)Dried denatured whey protein ingredient8470of this inventionSkim milk powder2239.6876.2Sugar6600Cream (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com