Oxide semiconductor devices, methods of manufacturing oxide semiconductor devices, display devices having oxide semiconductor devices, methods of manufacturing display devices having oxide semiconductor devices

a technology of oxide semiconductor and display device, which is applied in the direction of semiconductor devices, electrical devices, transistors, etc., can solve the problems of gate insulation layer etching damage easily generated on the surface of the gate insulation layer, gate insulation layer is frequently contaminated, and the voltage-current characteristics of the transistor may be deteriorated, etc., to achieve improved operation current, increase charge mobility, and enhance electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

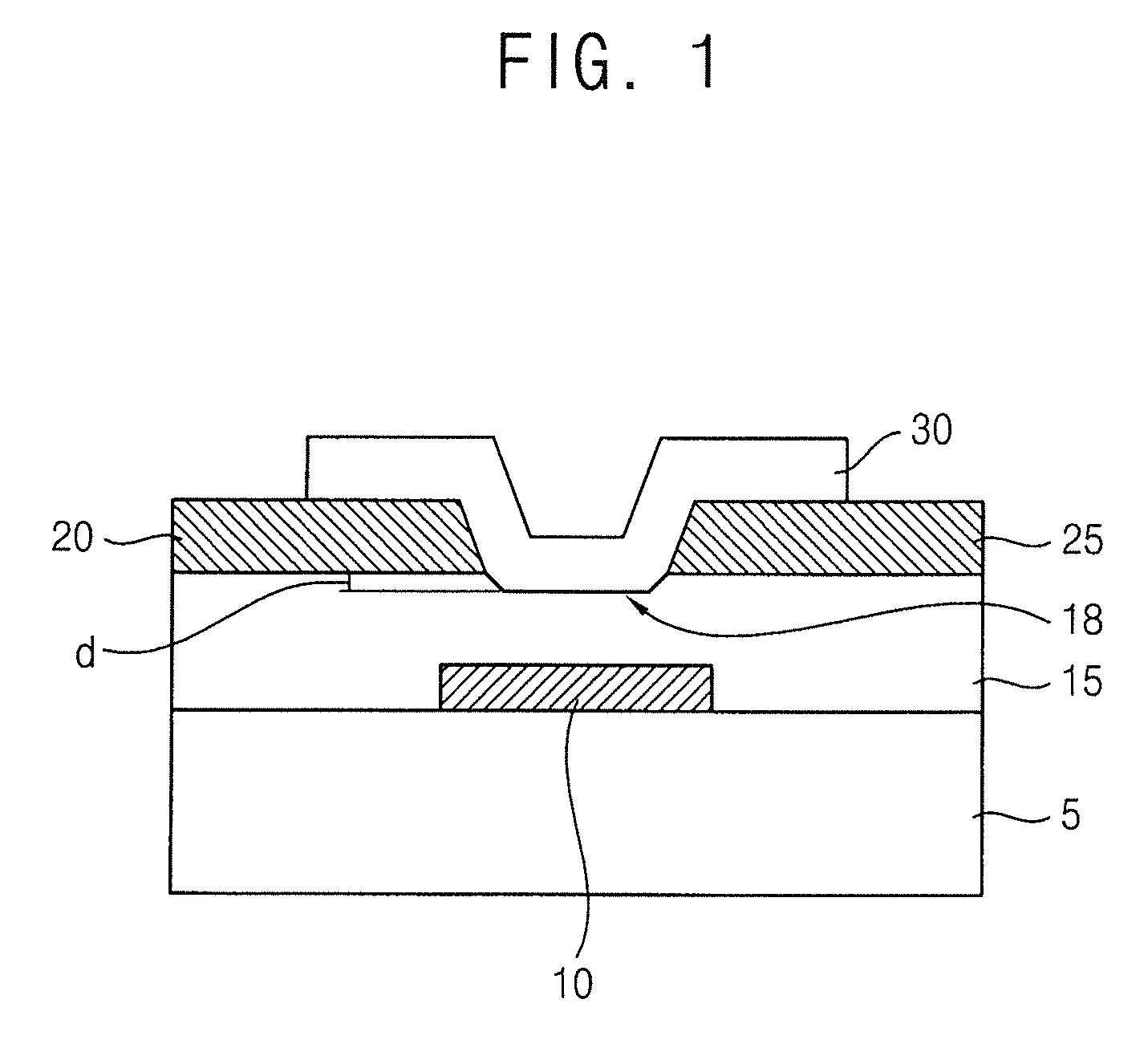

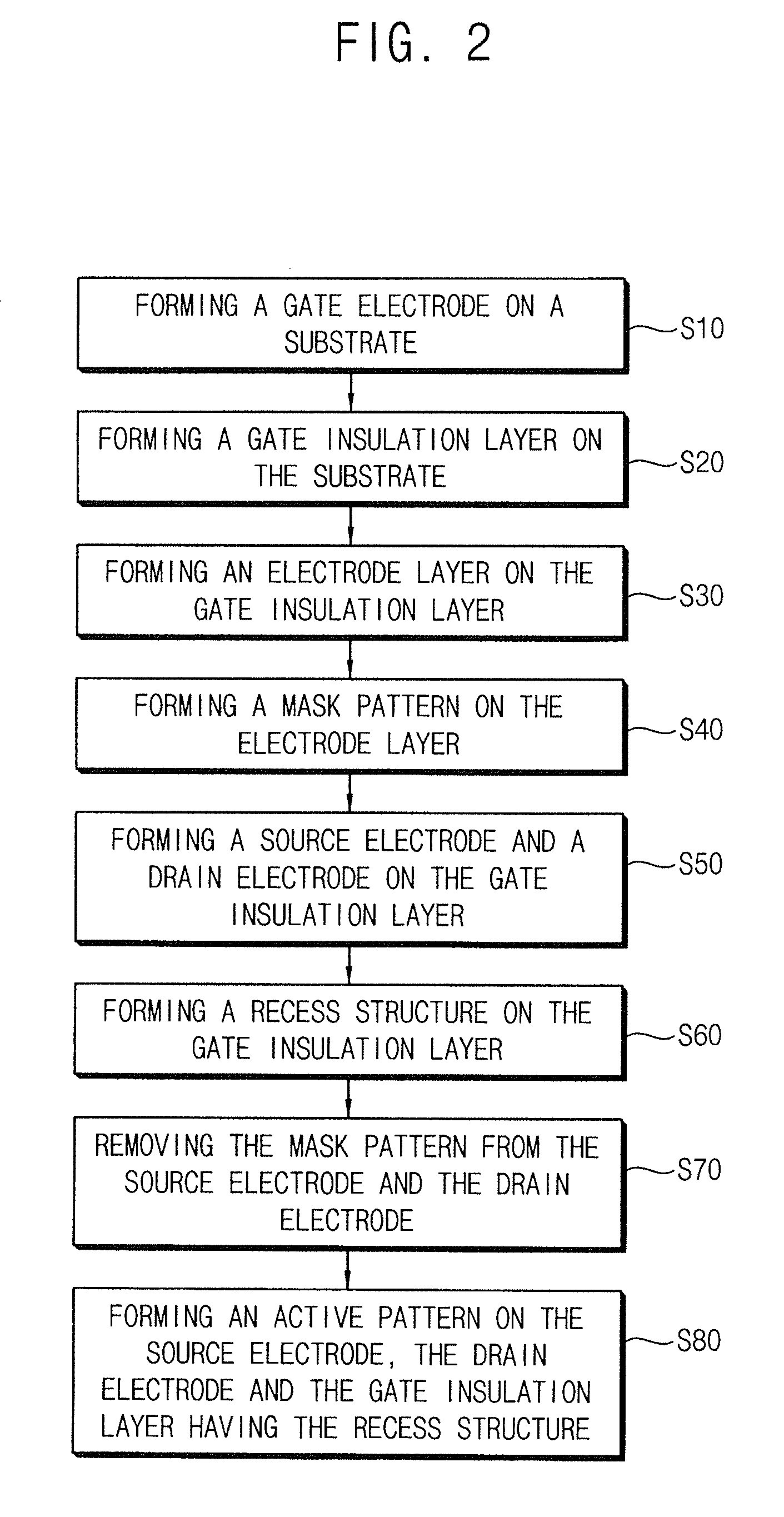

example 1

[0169]A gate electrode was formed on a substrate, and then a gate insulation layer was formed on the substrate to cover the gate electrode. After forming an electrode layer on the gate insulation layer, a source electrode and a drain electrode were formed on the gate insulation layer by patterning the electrode layer. A plasma treatment was performed on the gate insulation layer between the source and drain electrodes using a plasma generated from a mixture of sulfur hexafluoride (SF6) and oxygen (O2). A recess structure was formed on the gate insulation layer by the plasma treatment. An active pattern was formed on the gate insulation layer, the source electrode and the drain electrode, thereby obtaining an oxide semiconductor device.

example 2

[0170]A gate electrode was formed on a substrate, and then a gate insulation layer was formed on the substrate to cover the gate electrode. After forming an electrode layer on the gate insulation layer, a source electrode and a drain electrode were formed on the gate insulation layer by patterning the electrode layer. A cleaning treatment was performed on the gate insulation layer between the source and drain electrodes using a solution including hydrogen fluoride. A recess structure was formed on the gate insulation layer by the cleaning treatment. An active pattern was formed on the gate insulation layer, the source electrode and the drain electrode, so that an oxide semiconductor device was provided on the substrate.

example 3

[0171]After gate electrode formed on a substrate, a gate insulation layer was formed on the substrate to cover the gate electrode. After forming an electrode layer on the gate insulation layer, a source electrode and a drain electrode were formed on the gate insulation layer by patterning the electrode layer. A plasma treatment was primarily performed on the gate insulation layer between the source and drain electrodes using a plasma generated from a mixture of sulfur hexafluoride and oxygen. Then, a cleaning treatment was performed on the gate insulation layer using a solution including hydrogen fluoride. A recess structure was formed on the gate insulation layer by the plasma treatment and the cleaning treatment. An active pattern was formed on the gate insulation layer, the source electrode and the drain electrode, thereby obtaining an oxide semiconductor device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com