Purification of Carbon Dioxide

a carbon dioxide and purification technology, applied in the direction of liquefaction, separation processes, lighting and heating apparatus, etc., can solve the problems of reducing the reducing the power available for export, and not providing further details of how heat integration might be achieved, so as to achieve the effect of reducing the power consumption of the combined system, reducing the power consumption of the cpu, and reducing the power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

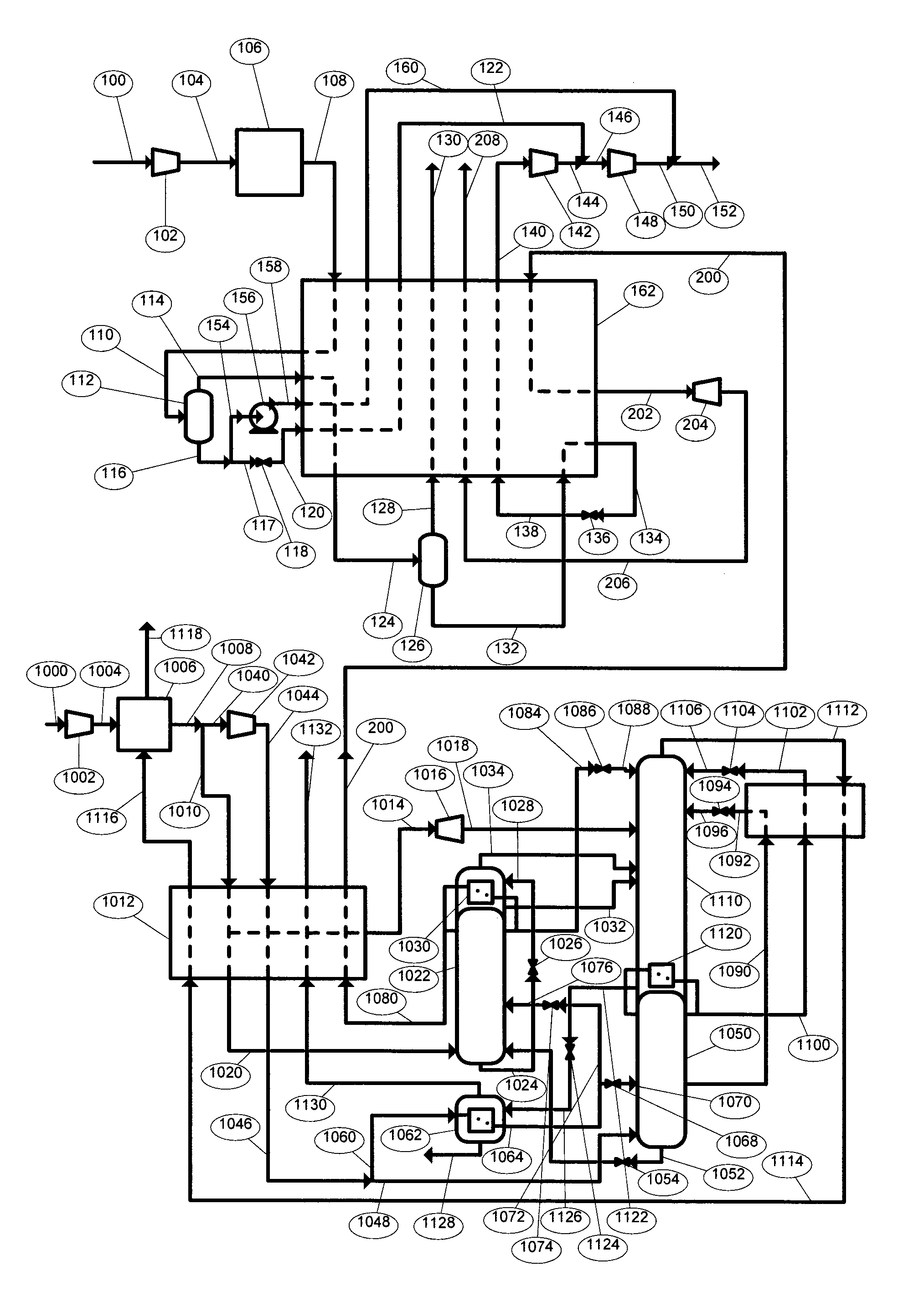

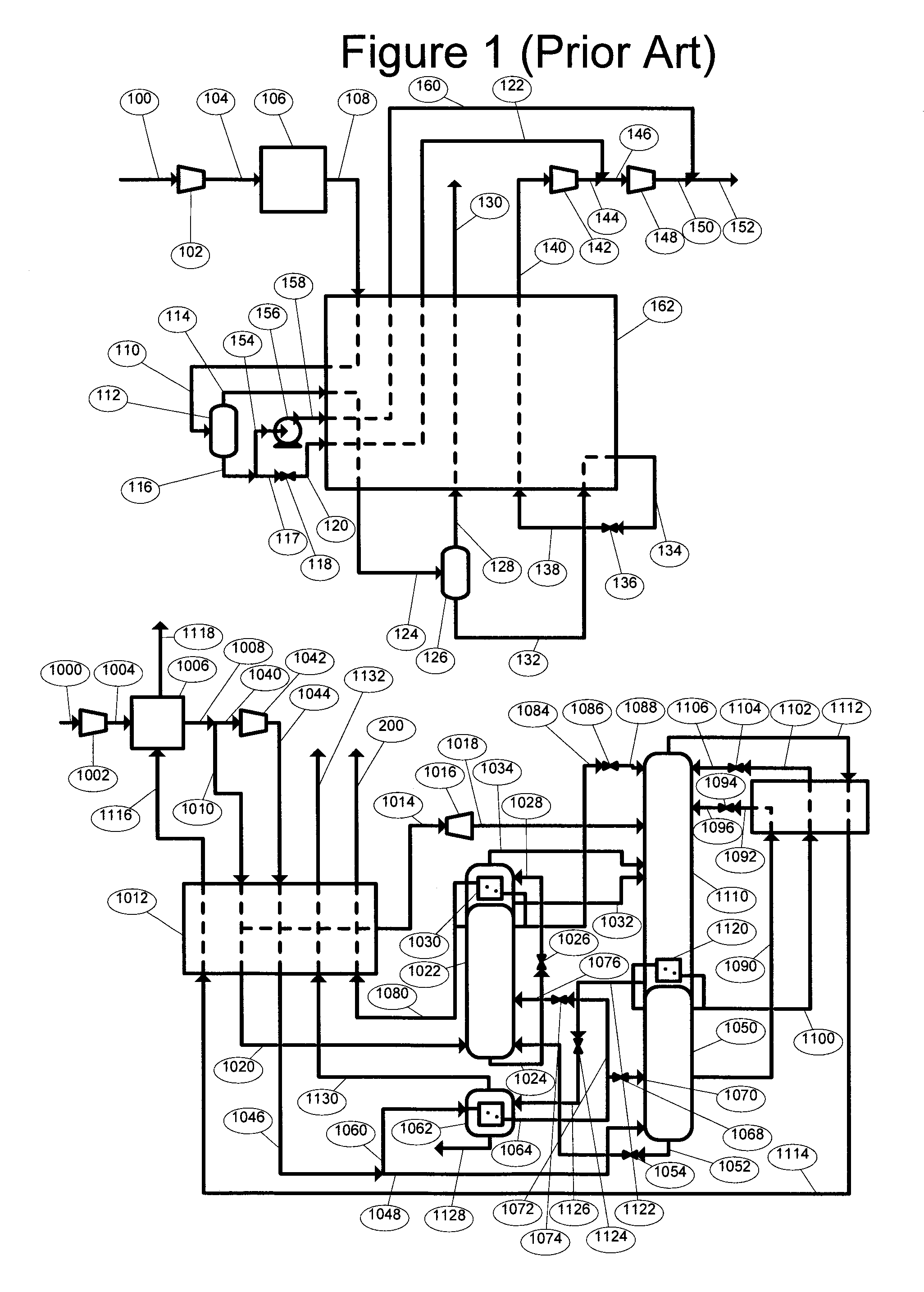

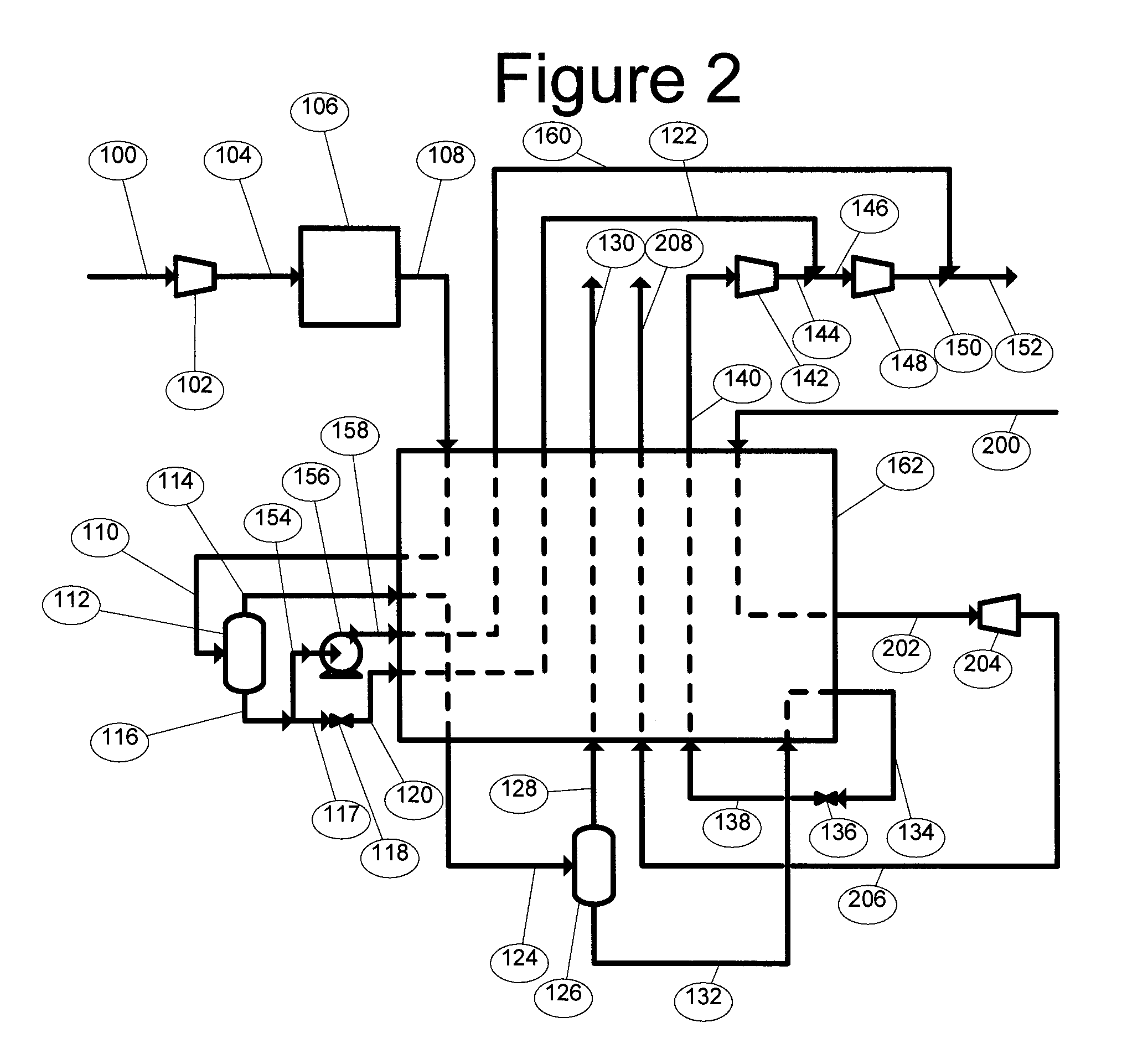

[0120]Similar computer simulations have been carried out to calculate key heat and mass balance and power consumption data for the integrated system depicted in FIG. 2b. The simulations were again based on an oxyfuel coal fired power station with a nominal net output of 500 MW.

[0121]As indicated in Table 3, the total ASU and CPU power consumption for this arrangement is 132540 kW which represents a significant reduction of 1.4% in total consumption over the prior art process of FIG. 1. This example demonstrates that efficiency of the ASU process is increased by withdrawing pressurised nitrogen from the ASU, and this more than offsets the lower efficiency of the refrigeration system in the CPU.

TABLE 3CPU line No.108110122124130140150152160200202208Temper-° C.20.0−37.111.7−53.511.711.720.018.211.76.8−20.511.7aturePressureBar30.0 (3)29.9 (3)18.4 (2)29.8 (3)29.7 (3)13.1 (1)110.0 (11)110.0 (11)110.0 (11)2.6 (0.3)2.5 (0.3)1.0 (0.1)(MPa)Molarkmol / s4.0584.0581.8341.5981.1710.4272.2612.8870....

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com