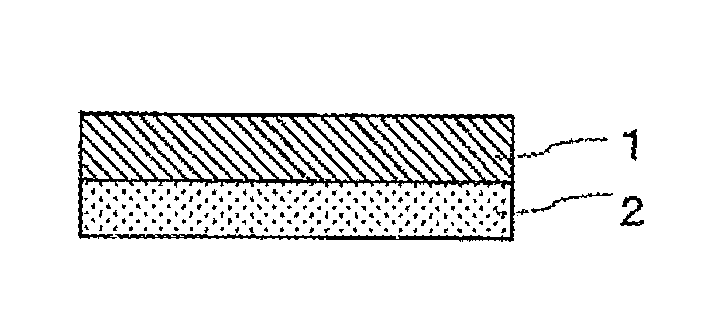

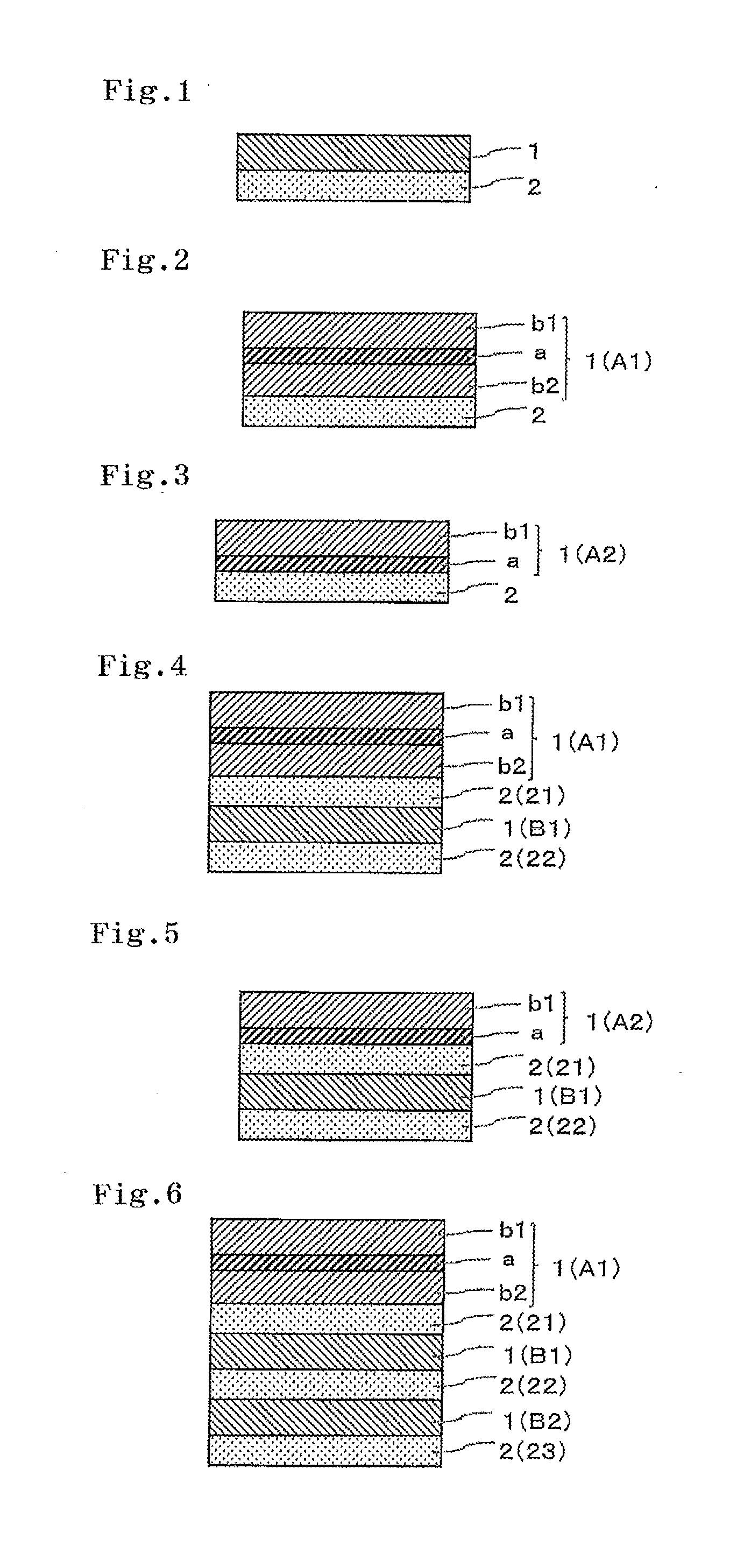

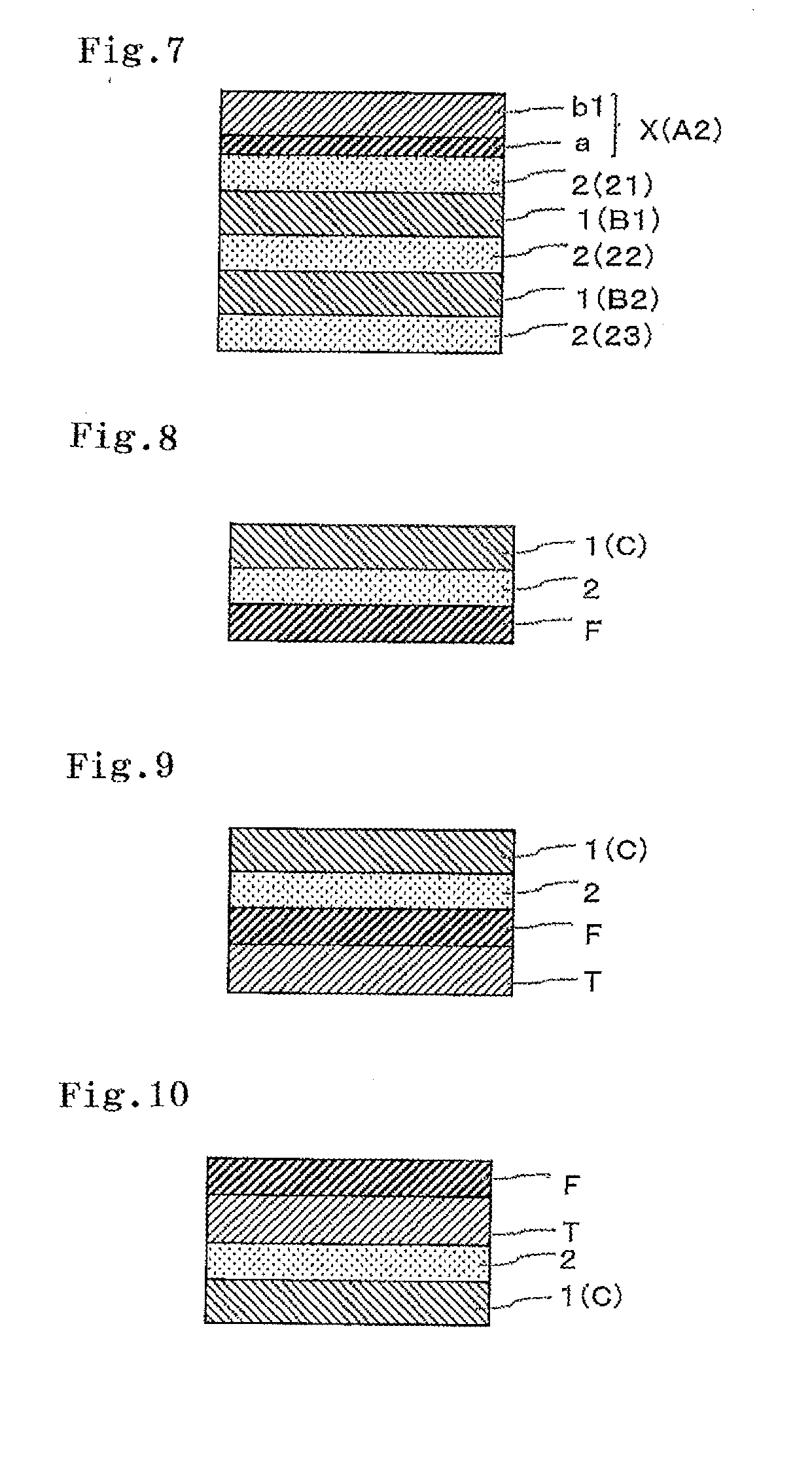

Adhesive optical film, manufacturing method for the same and image display device using the same

a technology of adhesive optical film and manufacturing method, which is applied in the direction of film/foil adhesives, polarizing elements, instruments, etc., can solve the problems of inability to form a pressure-sensitive adhesive layer, inability to reduce the thickness of the polarizing plate or the pressure-sensitive adhesive layer, and inability to achieve pressure-sensitive adhesive layer formation, etc., to achieve low thickness and reduce unevenness. , the effect of low level of irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

reference production example 1

(Process of Preparing Laminate)

[0142]The resin substrate used was an amorphous polyethylene terephthalate film (NOVACLEAR manufactured by Mitsubishi Plastics, Inc.) with a glass transition temperature of 80° C. A laminate film including the resin substrate and a polyvinyl alcohol layer was prepared as follows. First, the resin substrate was provided, which had a thickness of 100 μm. An aqueous solution of polyvinyl alcohol (NH26 manufactured by The Nippon Synthetic Chemical Industry Co., Ltd.) was then applied to the resin substrate. A 12-μm-thickpolyvinyl alcohol layer was formed by drying the applied solution at a temperature of 60° C. As a result, a laminate film was obtained.

(Insolubilization Process)

[0143]The resulting laminate film was immersed in an aqueous boric acid solution at a temperature of 30° C. for 30 seconds. The aqueous boric acid solution contained 4 parts by weight of boric acid and 100 parts by weight of water.

(Dyeing Process)

[0144]The prepared laminate film was...

reference production example 2

[0149]The resin substrate used was a polymethylpentene film (TPX manufactured by Mitsui Chemicals, Inc.) with a glass transition temperature of 30° C. Using a process similar to that of Reference Production Example 1, Reference Production Example 2 was performed in which a laminate film including the resin substrate and a polyvinyl alcohol layer (7 μm in thickness) containing adsorbed iodine was longitudinally and uniaxially stretched to an extent just before breaking point by allowing it to pass through a plurality of sets of rollers different in circumferential speed in an aqueous boric acid solution containing boric acid and potassium iodide at a temperature of 60° C. In this process, the stretch ratio (maximum stretch ratio) was 5.5 times.

[0150]As used herein, the phrases “just before breaking point” and the “maximum stretch ratio” mean a stretch ratio about 0.2 (times) lower than the breaking stretch ratio determined in advance as in the case of Reference Production Example 1. ...

example 1

(Preparation of Polarizing Plate)

[0323]A polarizing plate was prepared by bonding 40-μm-thick triacetylcellulose films (KC4UY manufactured by Konica Minolta Holdings, Inc., 0.3% in haze value) as first and second transparent protective films to both sides of the polarizer (1) with an polyvinyl alcohol-based adhesive.

(Preparation of Pressure-Sensitive Adhesive Coating Liquid)

[0324]The solution of the acrylic pressure-sensitive adhesive (1) prepared in Production Example 1 was diluted with ethyl acetate to a solid concentration of 15%, so that a pressure-sensitive adhesive coating liquid was obtained. The pressure-sensitive adhesive coating liquid had a viscosity of 65 P.

(Preparation of Pressure-Sensitive Adhesive Polarizing Plate)

[0325]The pressure-sensitive adhesive coating liquid prepared as described above was applied to one side of a 38-μm-thick, silicone-treated, polyethylene terephthalate (PET) film (MRF38 manufactured by Mitsubishi Polyester Film) with a fountain die coater so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com