Gallium nitride substrate and optical device using the same

a technology of gallium nitride and substrate, which is applied in the direction of semiconductor/solid-state device testing/measurement, instruments, semiconductor lasers, etc., can solve the problems of deterioration of poor crystal quality of epitaxial growth layer, and decrease in yield, so as to reduce residual carbon and enhance the crystalline quality of epitaxial layer grown on gallium nitride substrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0050]In Example 1, a GaN single crystal was grown by the VAS method to make a GaN substrate.

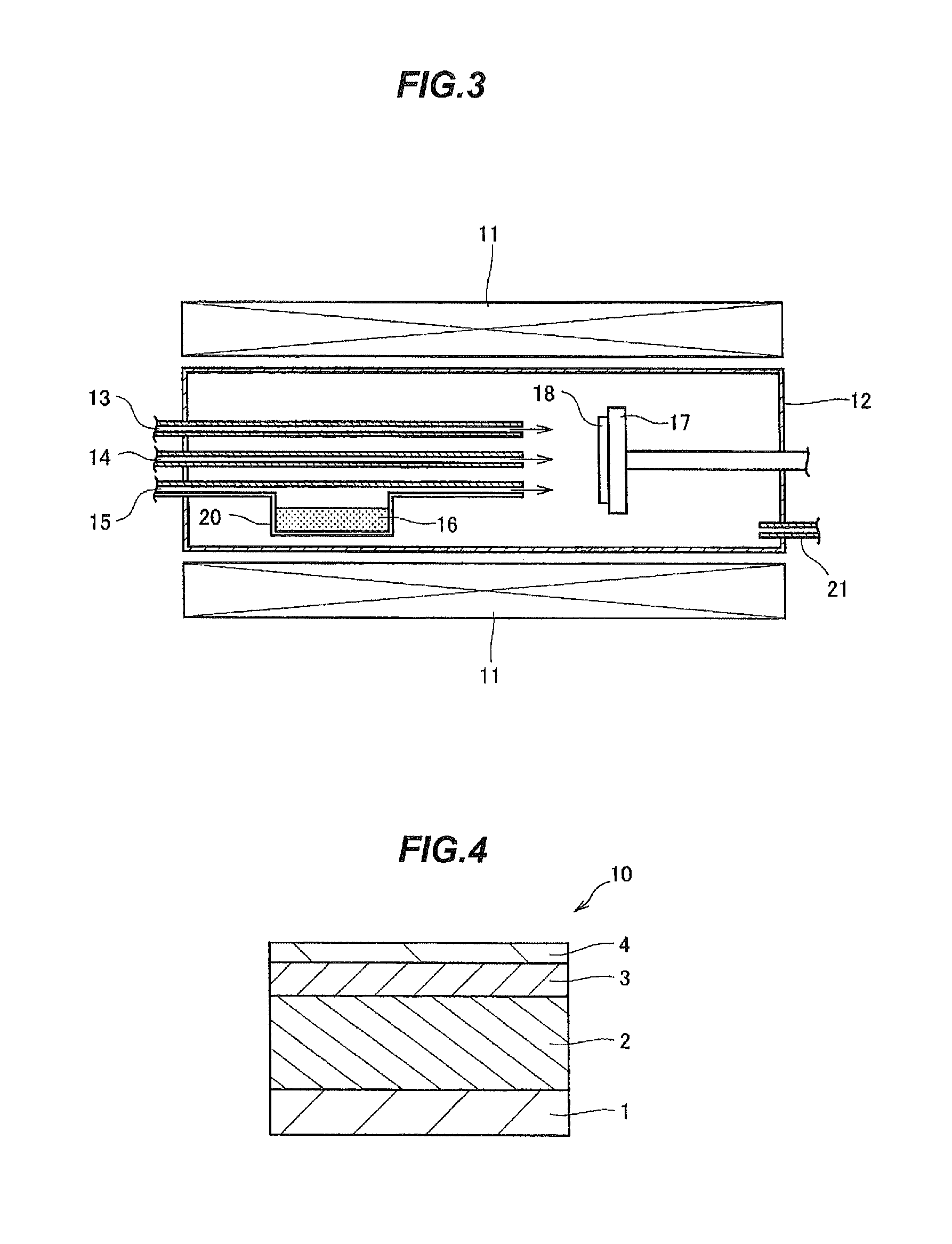

[0051]Firstly, a void-containing substrate was prepared. For making the void-containing substrate, a 500 nm-thick GaN base layer was formed on a sapphire substrate (3.5 inches in diameter) by the MOVPE method, etc., a 30 nm-thick Ti layer was deposited on a surface thereof, and subsequently, heat treatment (at a temperature of 1000° C.) was carried out in a mixture gas of H2 and NH3 for 30 minutes to form voids in the GaN layer while converting the Ti layer into TiN having a mesh structure.

[0052]The void-containing substrate was placed on the substrate holder 17 in the HVPE apparatus shown in FIG. 3, and was heated in the reaction tube 12 at atmospheric pressure so as to have a substrate temperature of 1050° C. The initial nucleation conditions were as follows: 5×10−2 atm of NH3 gas was introduced together with 6×10−1 atm of N2 gas as a carrier gas from the reaction gas inlet tube 13, 5×10−3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| accelerating voltage | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com