Physical process for the recovery of iron from magnetic cementitious spherical particles generated from metallurgical byproducts

a technology of physical processes, which is applied in the field of physical processes for the recovery of iron from magnetic cementitious spherical particles generated from metallurgical byproducts, can solve the problems of low throughput rate, limited amount of slag that can be used in this process, and inability to use magnetic iron in any application, so as to facilitate the transportation of compacted materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

General process for the recovery of iron from magnetic cementitious spherical particles produced from the E.B.O.F.

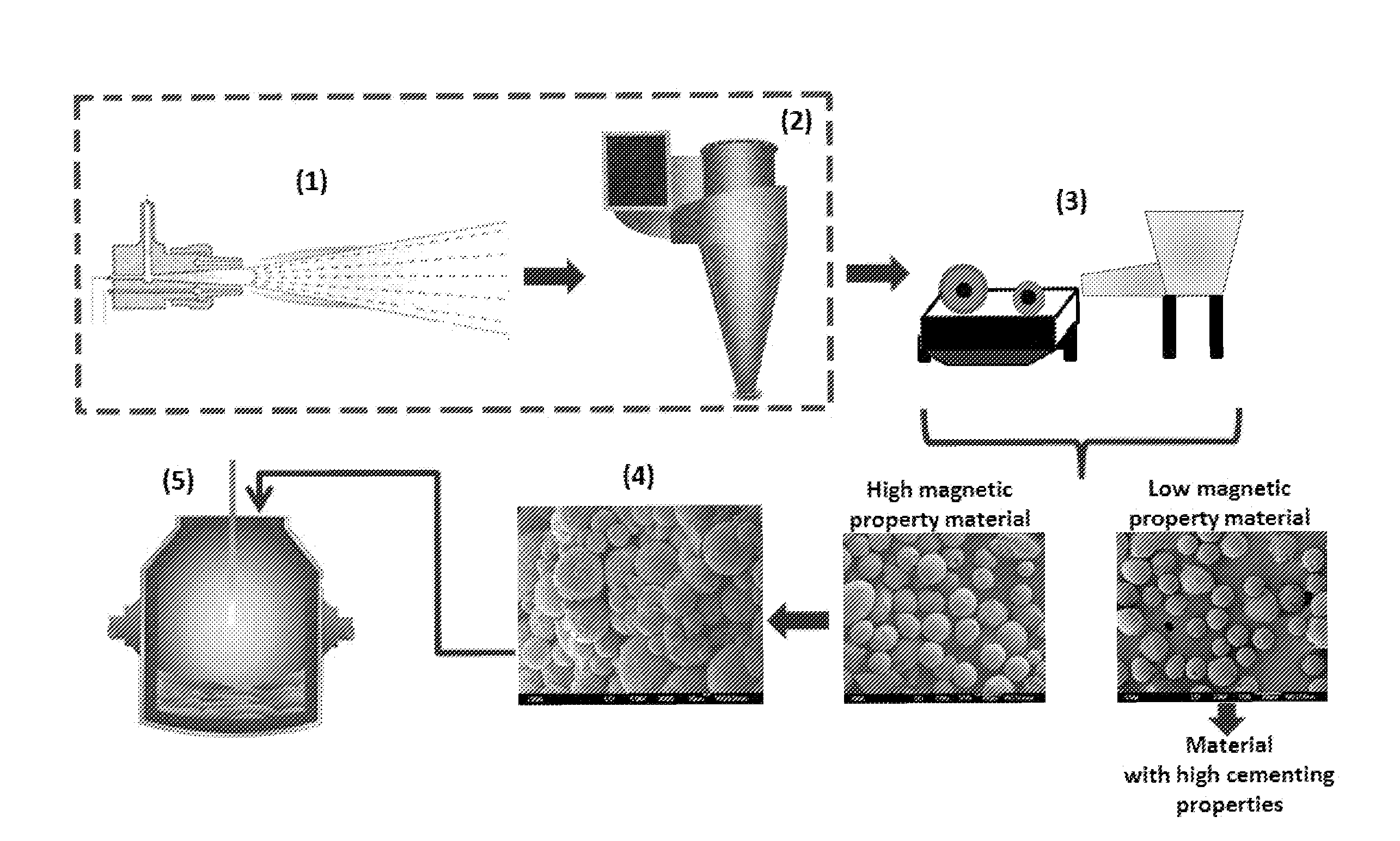

[0020]The process set forth in FIG. 1, shows a section enclosed within a dashed line box, this section corresponds to Patent Application No. MX / a / 2011 / 013658. However, once the new material, cooled off (magnetic cementitious spherical particles), leaves the collector, it passes to a magnetic separation device capable of classify the material into two or more fractions according to the applied magnetic field. Once separation is achieved, basically in two fractions: (1) an iron-rich and highly magnetic one, and (2) another cementitious fraction with practically very little or almost no magnetic properties, said highly magnetic fraction is mixed with an aqueous solution, which may or may not contain silica nanoparticles to form a magnetic aggregate. Adding silica nanoparticles promotes the chemical reaction with products generated by the hydration of the highly magnetic sph...

example 2

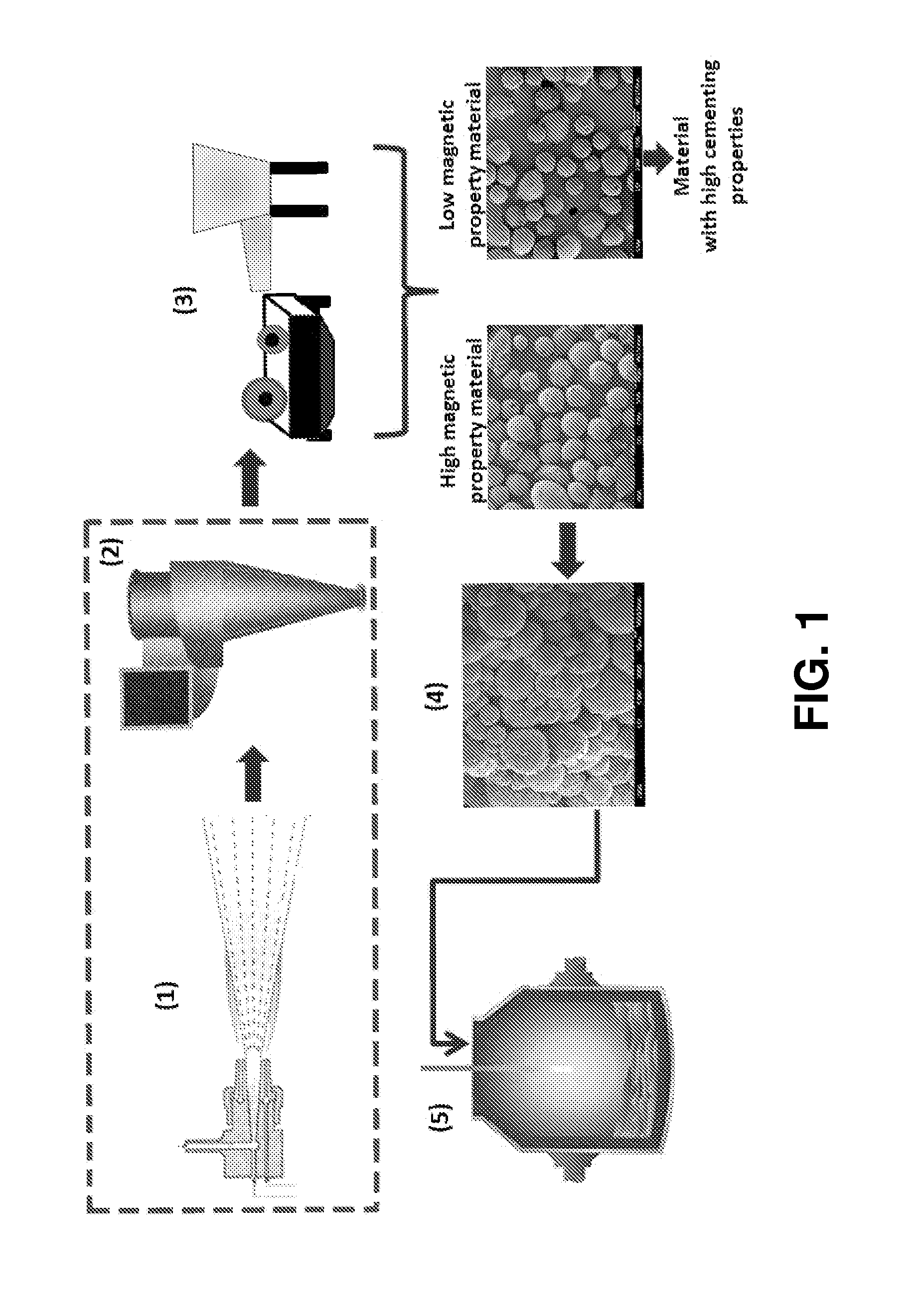

Characterization by X-Ray Diffraction (XRD) of the Precursor Material (B.O.F.S.) and the Separated Fraction of Highly Magnetic Spherical Particles

[0021]The XRD pattern of the original B.O.F.S, and the fraction of highly magnetic spherical particles, was obtained using an X-ray diffractometer, model Siemens 500, with Kα radiation of Cu (λ=1.5418 Å), at 35 kw and 25 mA. The diffractogram of FIG. 2 indicates the presence of different original crystalline phases of the B.O.F.S. (bottom XRD), such as: Wustite (FeO), Magnetite (Fe3O4), Brownmillerite (Ca2AlFeO5), Larnite (CaSiO4), Bixbyite (Mn2O3), Diopside (CaMg(SiO3)2) and Merwinite (Ca3Mg(SiO4)). On the other hand, the upper difractrogram corresponds to the fraction of highly magnetic spherical particles, and can be noticed the presence of phases such as Magnetite (Fe3O4), Maghemite (γ-Fe2O3), Mervinite (Ca3Mg(SiO4)), Bixbyite (Mn2O3), Diopside (CaMg(SiO3)2), Tricalcium Aluminate (3CaOAl2O3), Dicalcium Silicate (2CaO.SiO2) and Tricalci...

example 3

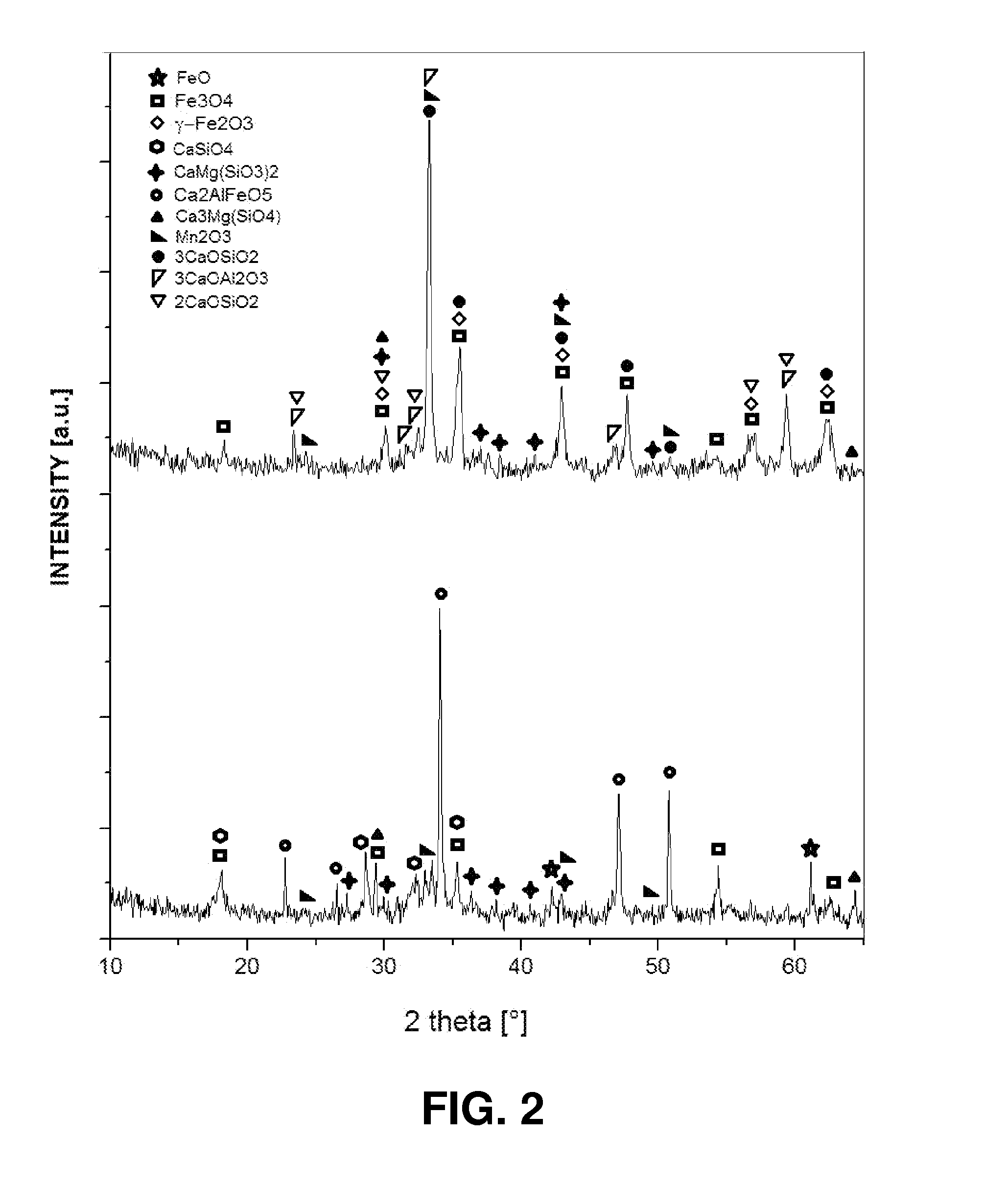

Morphology and Chemical Composition by Field Emission Scanning Electron Microscopy of the Separated Fraction of Highly Magnetic Spherical Particles

[0022]Morphological analyses of the spherical particles that form the highly magnetic fraction were performed by Field Emission Scanning Electron Microscopy, using a JEOL model JSM-7401F equipment and its respective energy dispersive X-rays spectroscopy (EDS) equipment Noran-200, to determine the semiquantitative chemical composition was performed through the analysis by EDS. FIG. 3 shows the photomicrograph of the Field Emission Scanning Electron Microscopy of the separated fraction of highly magnetic spherical particles, where the surface of the spheres, and their sphericality and roughness. Moreover, and as indicated in Table 2, all oxides present in the magnetic cementitious spherical particles remain very similar in proportion and amounts to those shown by the precursor used (B.O.F.S.) However, and about the sulfur content (reported ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com