Liquid crystal display device and touch panel

a technology touch panel, which is applied in semiconductor devices, instruments, computing, etc., can solve the problems of varying the power consumption of liquid crystal display device, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Structure of Liquid Crystal Panel

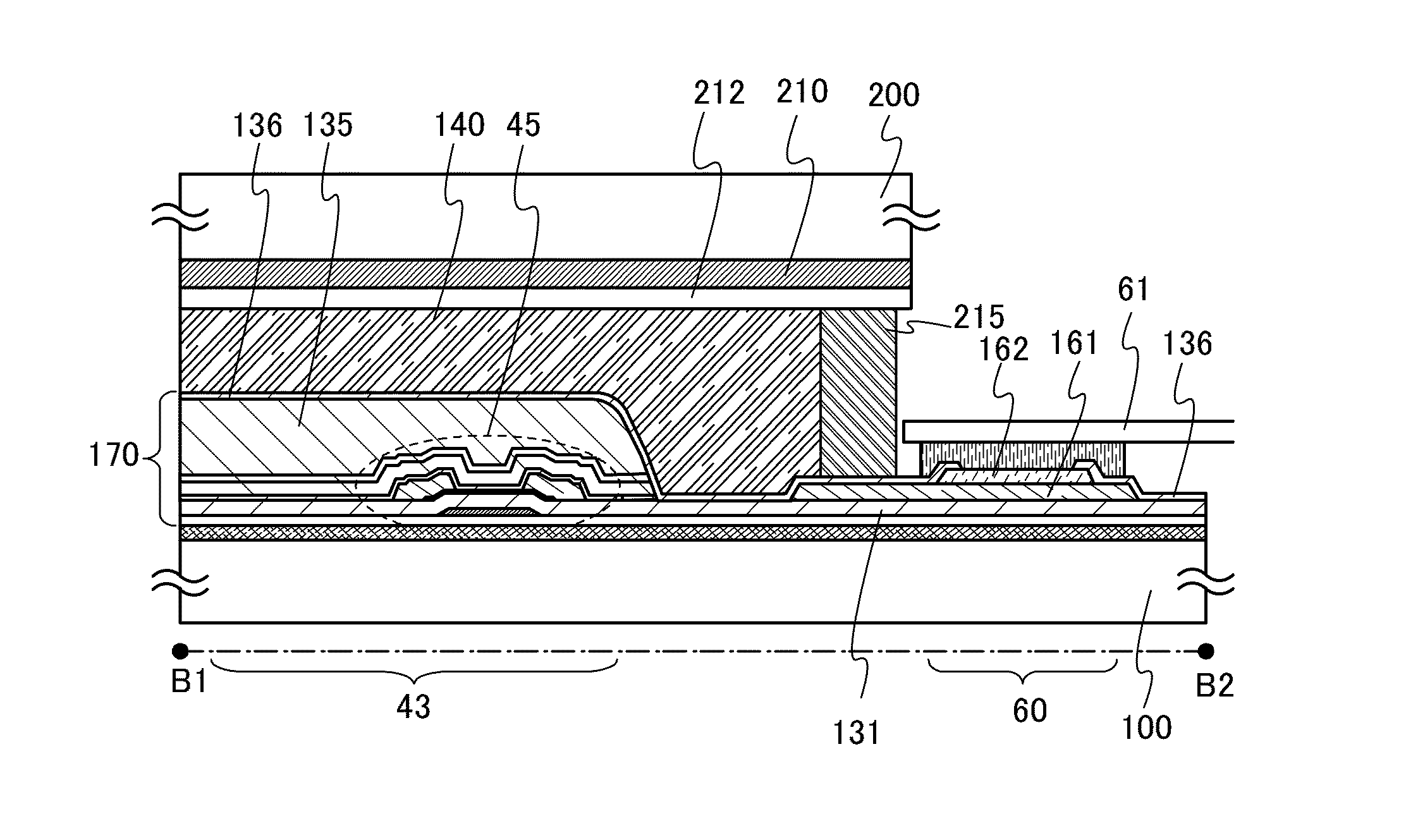

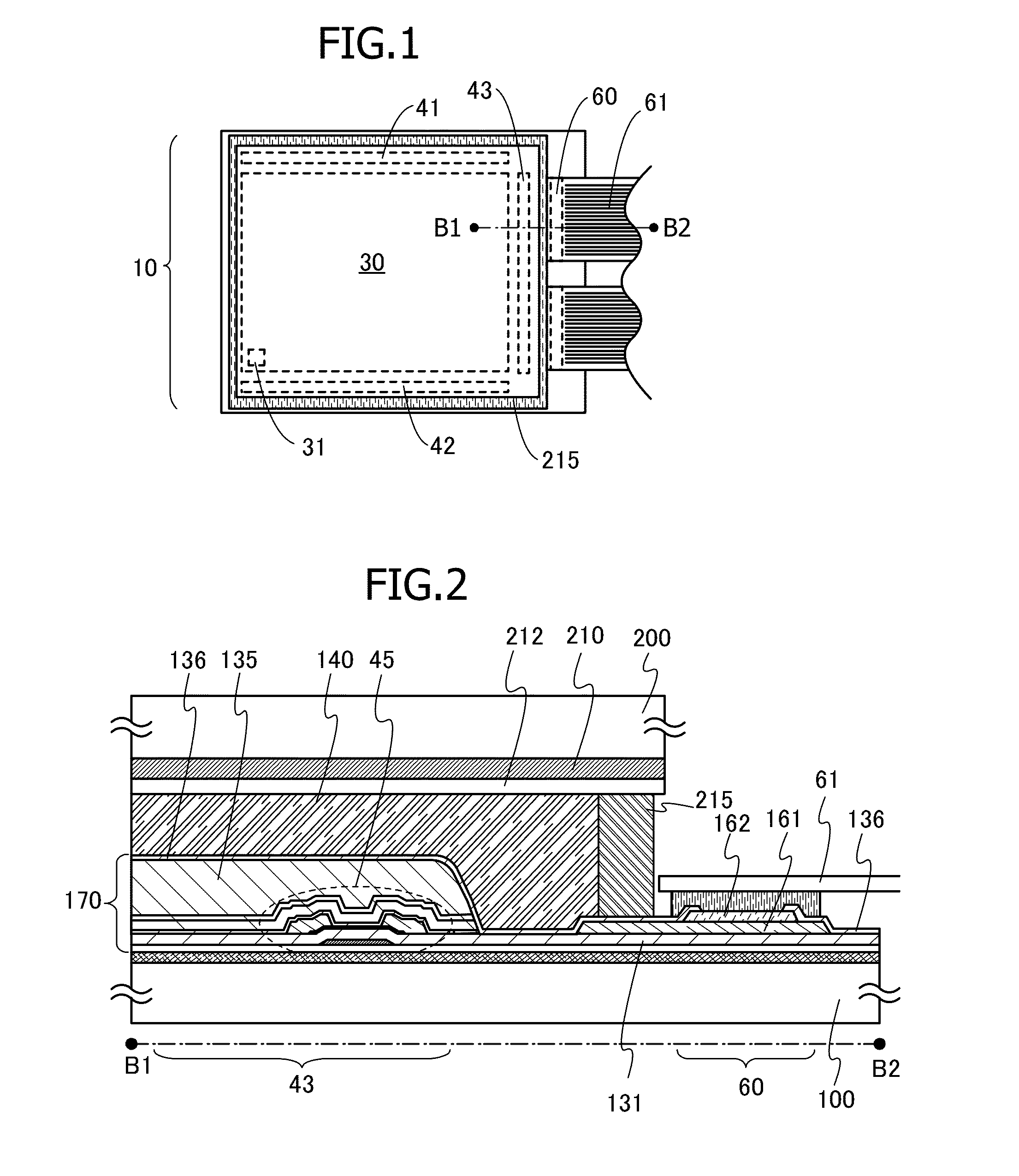

[0062]A liquid crystal panel of this embodiment is described using FIG. 1, FIG. 2, FIG. 3, FIG. 4, FIG. 5, FIG. 14, and FIG. 23. FIG. 1 is a plan view illustrating an example of a structure of a liquid crystal panel 10. FIG. 2 is a cross-sectional view illustrating an example of a structure of the liquid crystal panel 10 and corresponds to a cross-sectional view taken along line B1-B2 in FIG. 1.

[0063]FIG. 23 is a block diagram illustrating an example of a structure of the liquid crystal panel 10. The liquid crystal panel 10 includes a display portion 30, a scan line driver circuit 41, a scan line driver circuit 42, and a data line driver circuit 43. The display portion 30 includes a plurality of pixels 31 connected to scan lines 110 and data lines 111. FIG. 14 is a circuit diagram illustrating a configuration example of the pixel 31.

[0064]The pixel 31 includes a transistor 35 and a liquid crystal element 36. The transistor 35 is a switching element w...

embodiment 2

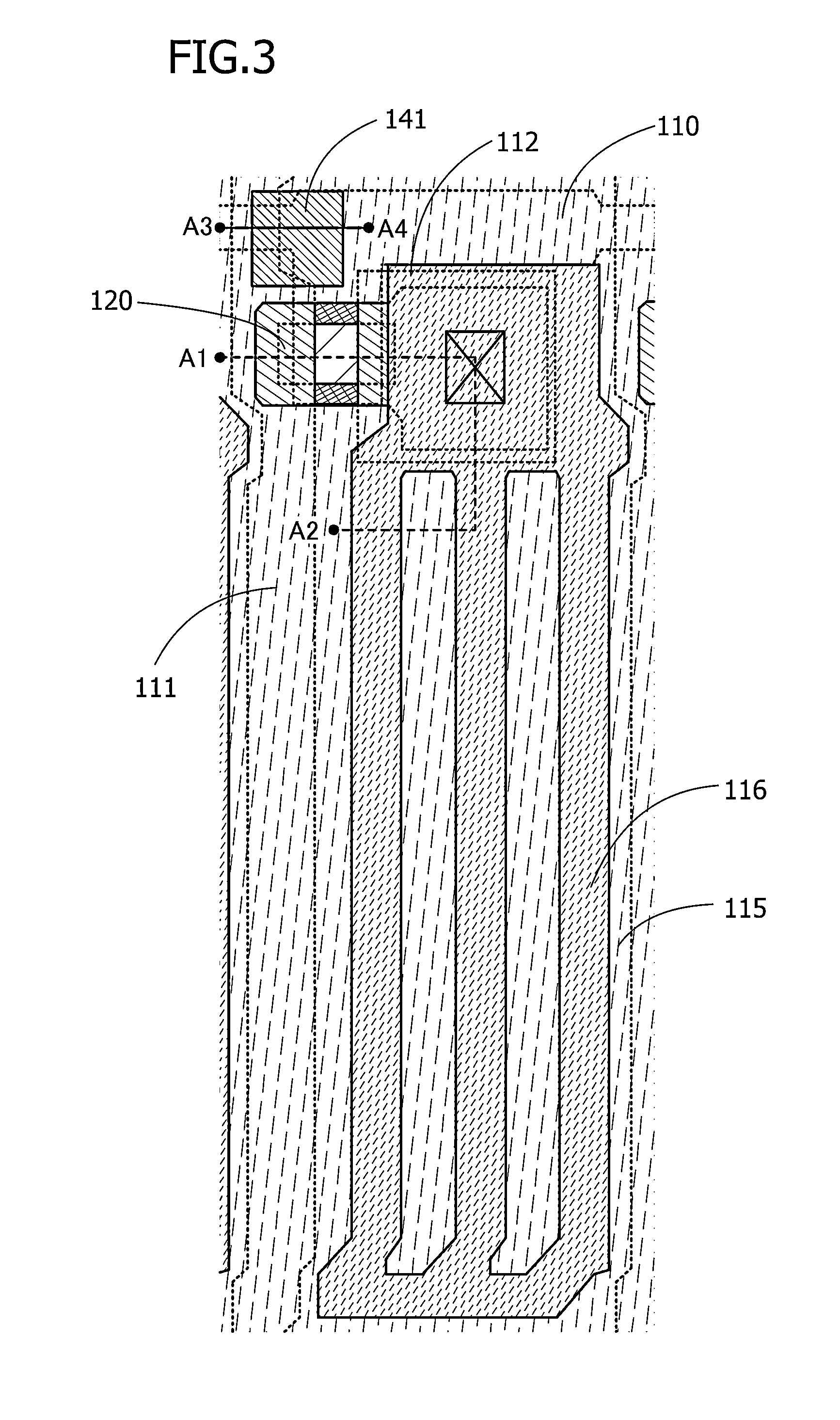

[0170]An oxide semiconductor film forming the semiconductor layer 120 is described in detail.

[0171]The oxide semiconductor film forming the semiconductor layer 120 is classified roughly into a single-crystal oxide semiconductor film and a non-single-crystal oxide semiconductor film. The non-single-crystal oxide semiconductor film includes any of an amorphous oxide semiconductor film, a microcrystalline oxide semiconductor film, a polycrystalline oxide semiconductor film, a c-axis aligned crystalline oxide semiconductor (CAAC-OS) film, and the like.

[0172]The amorphous oxide semiconductor film has disordered atomic arrangement and no crystalline component. A typical example thereof is an oxide semiconductor film in which no crystal part exists even in a microscopic region, and the whole of the film is amorphous.

[0173]The microcrystalline oxide semiconductor film includes a microcrystal (also referred to as nanocrystal) with a size greater than or equal to 1 nm and less than 10 nm, for...

embodiment 3

[0207]The liquid crystal panel 10 in FIG. 1 provided with a touch sensor (contact detector) can function as a touch panel.

[0208]In this embodiment, a touch panel is described with reference to FIG. 10, FIG. 11, and FIGS. 12A and 12B.

[0209]FIG. 10 is a cross-sectional view illustrating a structure example of a touch panel 400 using the liquid crystal panel 10. The touch panel 400 includes a capacitive sensor as a touch sensor. A polarizing plate 411 is attached to the outer side of the substrate 100, and a polarizing plate 412 is attached to the inner side of the substrate 200. Note that the polarizing plate 412 may be provided on the outer side of the substrate 200.

[0210]A common electrode 421 over the substrate 100 serves as a common electrode of a pixel and an electrode of a capacitor in the touch sensor. An electrode 422 is provided on the outer side of the substrate 200. In the case where the polarizing plate 412 is provided on the outer side of the substrate 200, the electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com