Precoated fin material for heat exchangers and heat exchanger

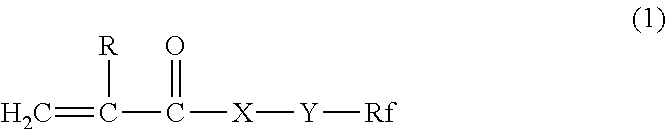

a technology of heat exchanger and fin, which is applied in the direction of coating, light and heating apparatus, laminated elements, etc., can solve the problems of reducing the quantity of air to flow into the heat exchanger, adhesion to the surface of the fin, and clogging of the fin between the fins, etc., to achieve excellent condensed water removal effect, excellent anti-frizz formation effect, and excellent anti-frizz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

production example 1

Solution of Carboxyl Group-Containing Acrylic Resin (ca-1)

[0101]850 parts of n-butanol were heated to 100° C. in a stream of nitrogen, and then a monomer mixture and a polymerization initiator “450 parts of methacrylic acid, 450 parts of styrene, 100 parts of ethyl acrylate, and 40 parts of t-butyl peroxy-2-ethylhexanoate” were dropped therein over 3 hr. After the dropping, the resultant mixture was aged for 1 hr. Next, a mixed solution of 10 parts of t-butyl peroxy-2-ethylhexanoate and 100 parts of n-butanol was dropped to the aged product over 30 min, and after the dropping, the resultant mixture was aged for 2 hr. Next, 933 parts of n-butanol and 400 parts of ethylene glycol monobutyl ether were added to the aged product to provide a solution of a carboxyl group-containing acrylic resin (ca-1) having a solid content of about 30%. The resultant resin had a resin acid value of 300 mgKOH / g and a weight-average molecular weight of about 17,000.

production example 2

Solution of Carboxyl Group-Containing Acrylic Resin (Ca-2)

[0102]1,400 parts of n-butanol were heated to 100° C. in a stream of nitrogen, and then a monomer mixture and a polymerization initiator “670 parts of methacrylic acid, 250 parts of styrene, 80 parts of ethyl acrylate, and 50 parts of t-butyl peroxy-2-ethylhexanoate” were dropped therein over 3 hr. After the dropping, the resultant mixture was aged for 1 hr. Next, a mixed solution of 10 parts of t-butyl peroxy-2-ethylhexanoate and 100 parts of n-butanol was dropped to the aged product over 30 min, and after the dropping, the resultant mixture was aged for 2 hr. Next, 373 parts of n-butanol and 400 parts of ethylene glycol monobutyl ether were added to the aged product to provide a solution of a carboxyl group-containing acrylic resin (ca-2) having a solid content of about 30%. The resultant resin had a resin acid value of 450 mgKOH / g and a weight-average molecular weight of about 14,000.

(2) Production of Ammonium Salt Group-C...

production example 3

Aqueous Dispersion of Ammonium Salt Group-Containing Modified Epoxy Resin (ae-1)

[0103]513 parts of a jER828EL (manufactured by Japan Epoxy Resins Co., Ltd., epoxy resin, epoxy equivalent: about 190, number-average molecular weight: about 380), 287 parts of bisphenol A, 0.3 part of tetramethylammonium chloride, and 89 parts of methyl isobutyl ketone were loaded, and were then subjected to a reaction for about 4 hr while being heated to 140° C. in a stream of nitrogen. Thus, an epoxy resin solution was obtained. The resultant epoxy resin had an epoxy equivalent of 3,700 and a number-average molecular weight of about 17,000.

[0104]Next, 667 parts of the solution of the carboxyl group-containing acrylic resin (ca-1) having a solid content of about 30% obtained in Production Example 1 were charged into the resultant epoxy resin solution, and were then uniformly dissolved by heating to 90° C. After that, 40 parts of deionized water were dropped to the solution at the temperature over 30 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com