Encapsulated Wear Particles

a technology of wear particles and wear parts, applied in the field of components wear surfaces, can solve the problems of limited practical use of diamond in industrial applications, high wear rate of ground engaging tools, and erosion of the surface of wear tools and wear members in sliding or impacting contact with other materials, so as to prolong the useful life and limit the degradation of diamond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

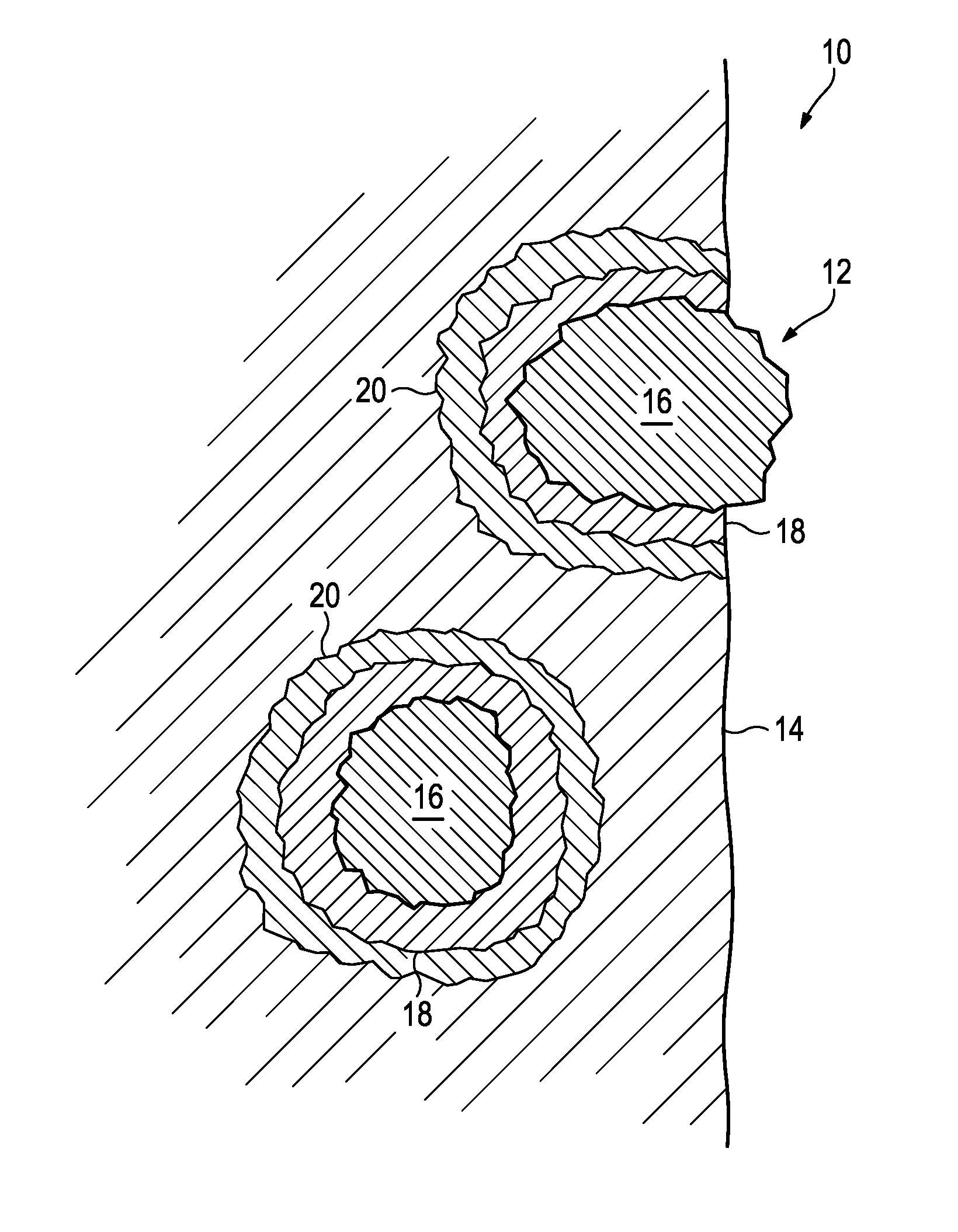

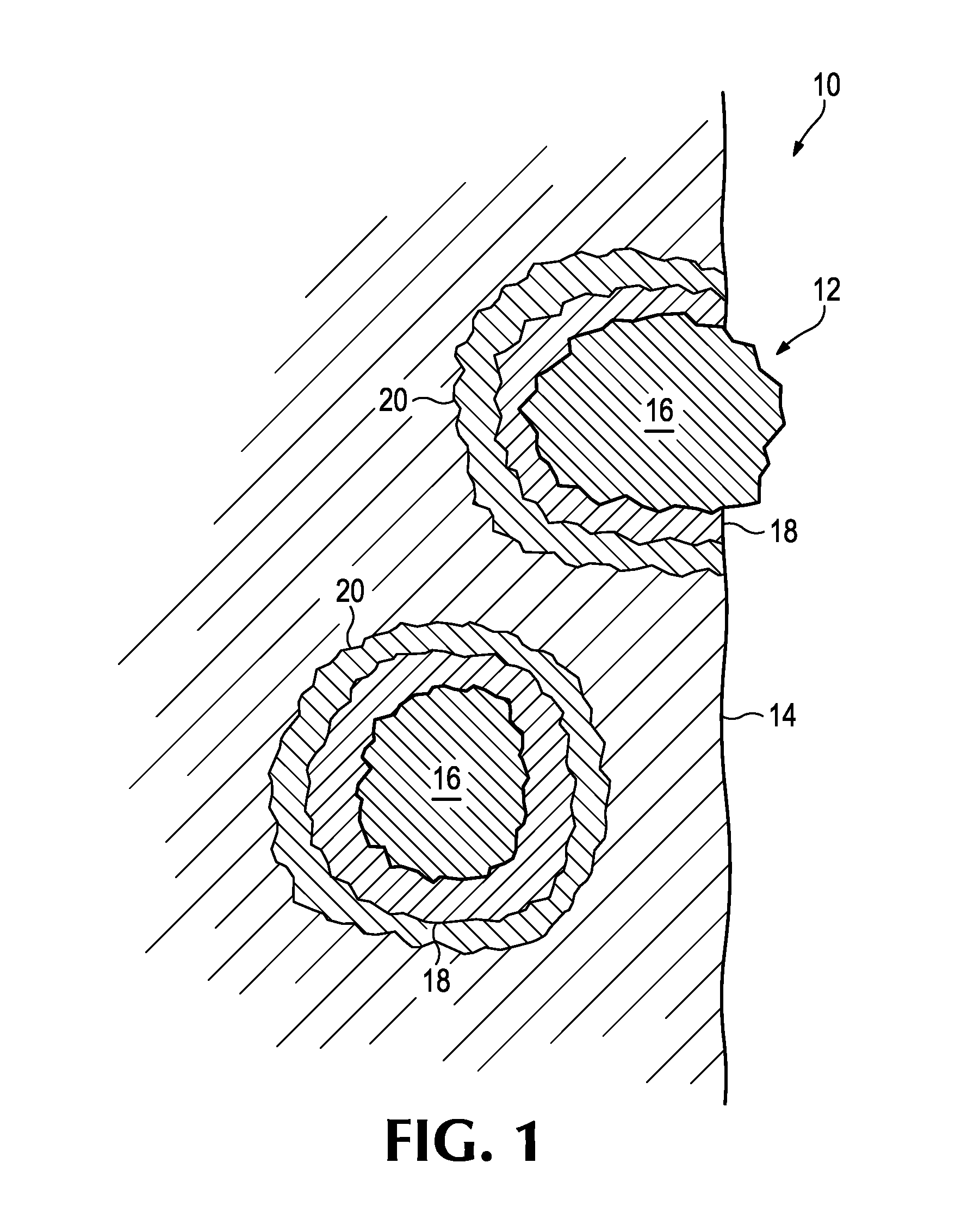

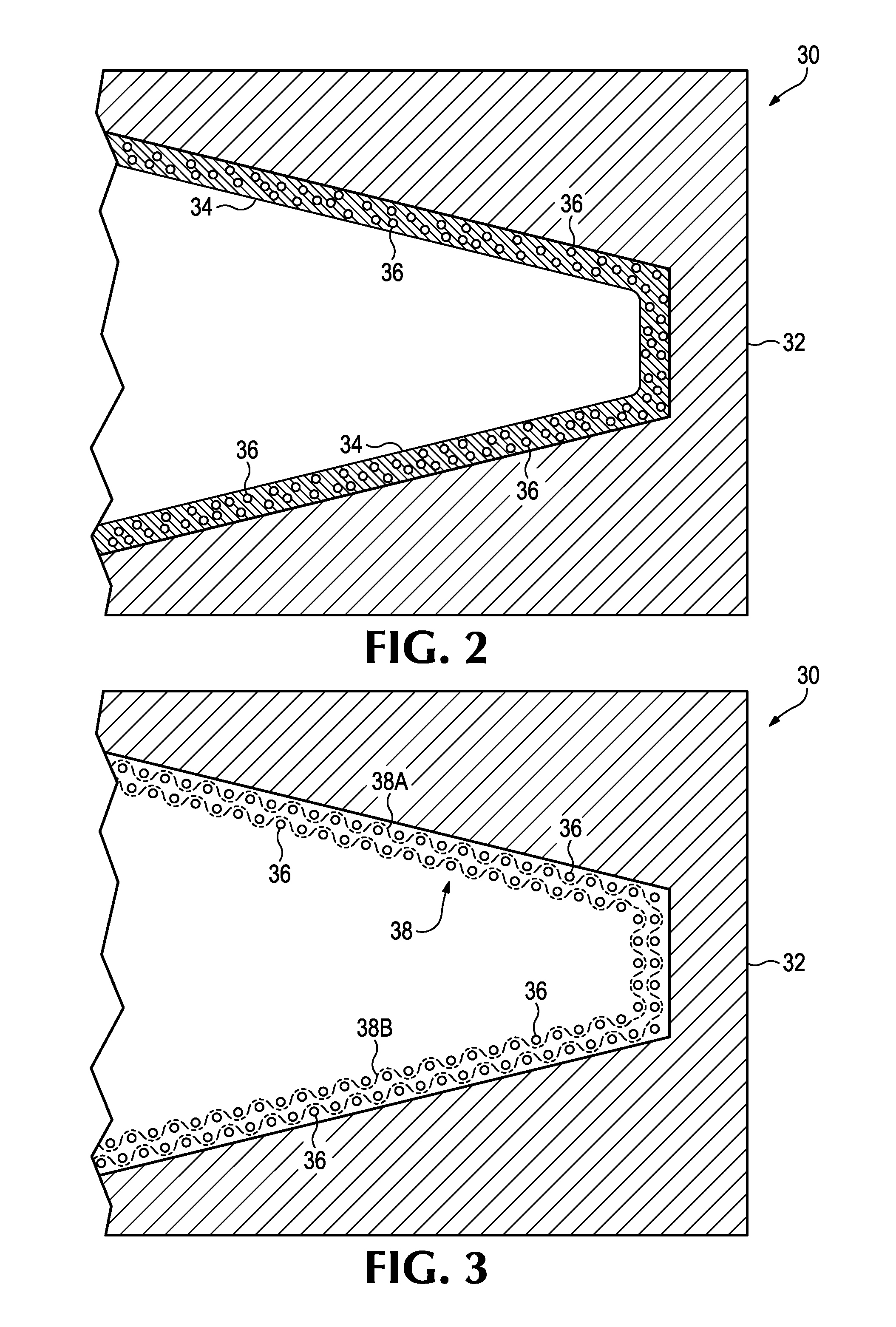

[0020]Many industrial operations involve tools and other parts that are subjected to abrasive materials. For example, tools in mining and drilling operations are quickly worn away by the material contact. Downtime for replacement of worn tools and components during industrial operations can significantly increase operating costs. Increasing the service life of wear members by increasing surface hardness to control erosion can limit downtime and increase operation efficiency.

[0021]Incorporating hard particles in a matrix forming the surface of a member can significantly increase wear resistance. Diamond as an extremely hard form of carbon is commonly used as an abrasive in grinding and cutting operations. Distributing diamond particles (or other hard particles) in a ferrous (or other metallic) cast wear member can provide advantageous wear characteristics to the tool or other part, but has in the past not been feasible on account of the degradation of diamond under high heat and / or c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com