Method Of Protecting A Building Or Group Of Buildings From Seismic Waves Using Gelifying Polymers

a technology of gelifying polymer and building, applied in the direction of building repair, foundation engineering, shock proofing, etc., to achieve the effect of increasing the maximum horizontal deformation capability and increasing the gap width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Placement of a Superabsorbent Polymer

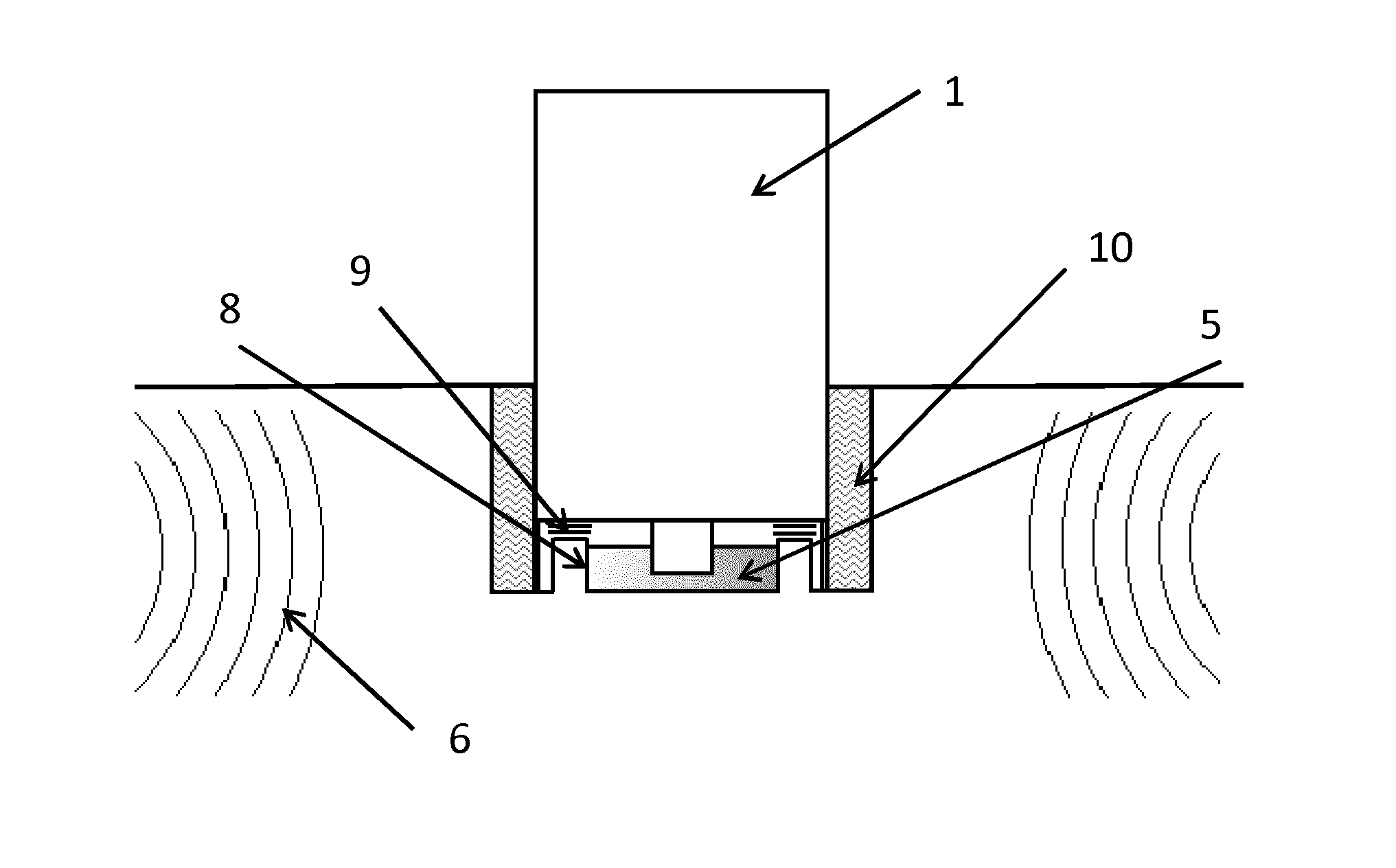

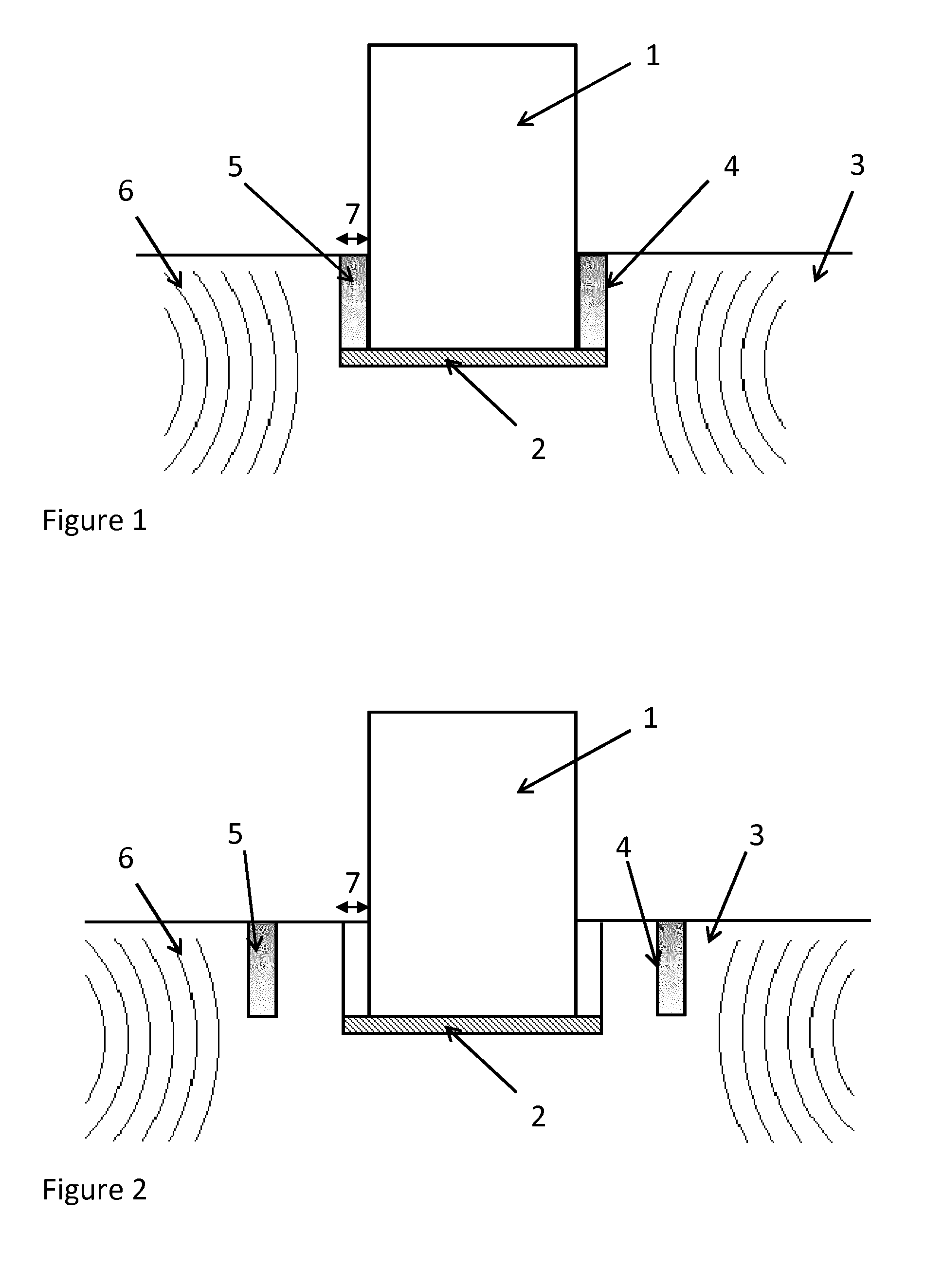

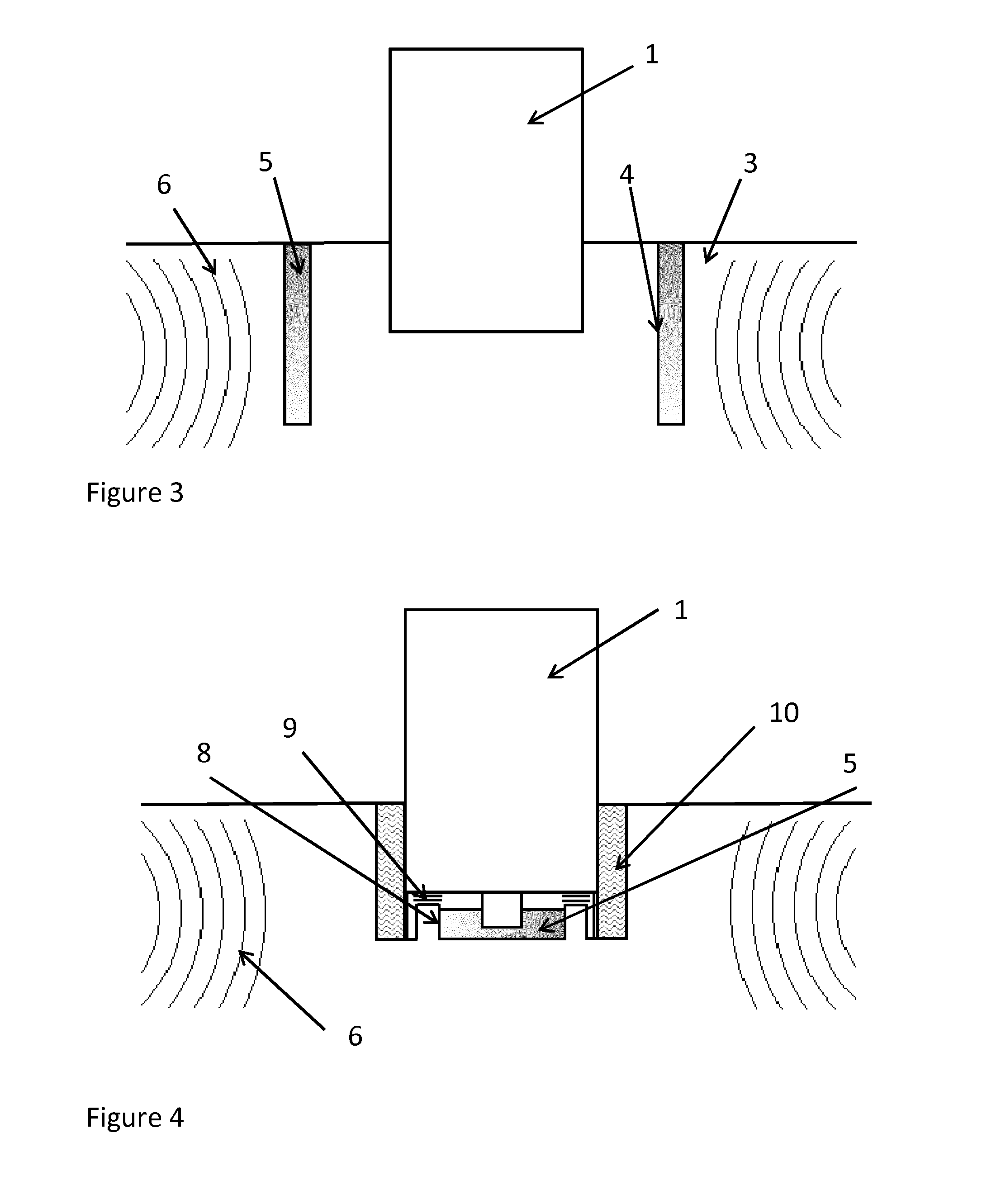

[0068]A superabsorbent polymer, in this instance an acrylamide / sodium acrylate / ATBS Na terpolymer (70 / -25 / 5), with grain size less than 5 mm, is swollen with water in a dissolving tank to about 150 to 200 times its volume. It is then transported by truck to the site, where it will be pumped to fill trenches 4 m deep and 40 cm wide around a sensitive building (FIG. 1 or 2).

example 2

Preparation and Use of a Gel Obtained from a Mixture of 2 Solutions

[0069]Two solutions are prepared:

[0070]The first A contains:[0071]Water 200 kg[0072]50% Acrylamide 9600 kg[0073]Methylene-bis-acrylamide (MBA) 300 kg[0074]Triethanolamine 300 kg

[0075]The second B contains:[0076]Water 9900 kg[0077]Sodium persulphate 297 kg

[0078]These two solutions are pumped and mixed and then the mixture is injected into the trench, in which polymerization takes place, forming a vibration-absorbing rigid gel (FIG. 1 or 2).

example 3

[0079]An acrylamide / sodium acrylate mixture (70-30 mol %) in solution at 50% and containing 3% of triethanolamine and 3% of MBA is transported in a tanker truck. At the site, a solution of 300 kg of sodium persulphate dissolved in 990 kg of water is added to this mixture. This permits in situ polymerization with a gel of good consistency.

[0080]A biocide, Protectol HT (triazine), is added in a small amount (0.01 wt %) for product stability.

[0081]A trench made 10 meters from the building and having the dimensions 5 meters deep and 50 cm wide is filled with the prepared gel.

[0082]The building is separated from the subjacent ground by a flexible footing, usually of rubber, and at the side walls by a trench containing gel. It has exceptional seismic performance.

[0083]The use or production of superabsorbent gels can be modified by a person skilled in the art for adapting to the local conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com