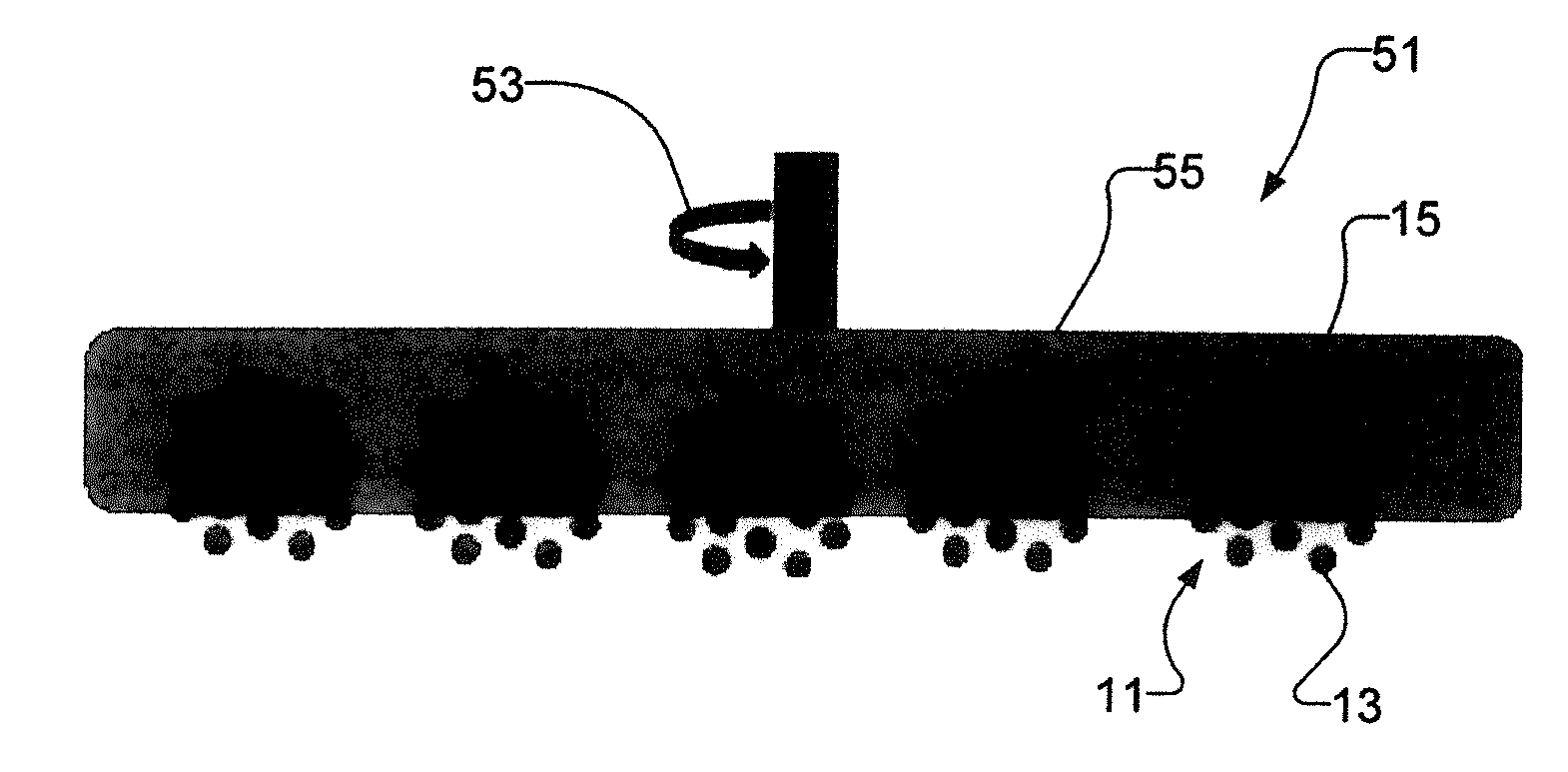

Chemical Mechanical Planarization Slurry Composition Comprising Composite Particles, Process for Removing Material Using Said Composition, CMP Polishing Pad and Process for Preparing Said Composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0132]This example demonstrates the preparation of a polyester latex in accordance with an embodiment of the invention.

[0133]To a 500 mL round bottom flask with overhead stirrer and thermocouple was added 50 g polyester resin (Reichold Fine-tone T-6694 resin, acid number 13 mg KOH / g resin, Tg=50-60° C.), 25 g methyl ethyl ketone, and 6.25 g isopropyl alcohol. The mixture was stirred at 250 rpm and maintained at 45° C. for 3 hours, after which 2.17 g 10% ammonium hydroxide solution (13.6 mmol) was added slowly. The mixture was stirred for a further five minutes, after which 5 g methacryloxypropyl-trimethoxysilane (MPS) was added. This mixture was stirred for 10 minutes, after which 150 g deionized water was slowly added to produce a dispersion. The mixture was heated to 95-98° C. and about 40 g liquid was distilled off. The heating mantle was removed and the reaction mixture cooled to room temperature.

example 2

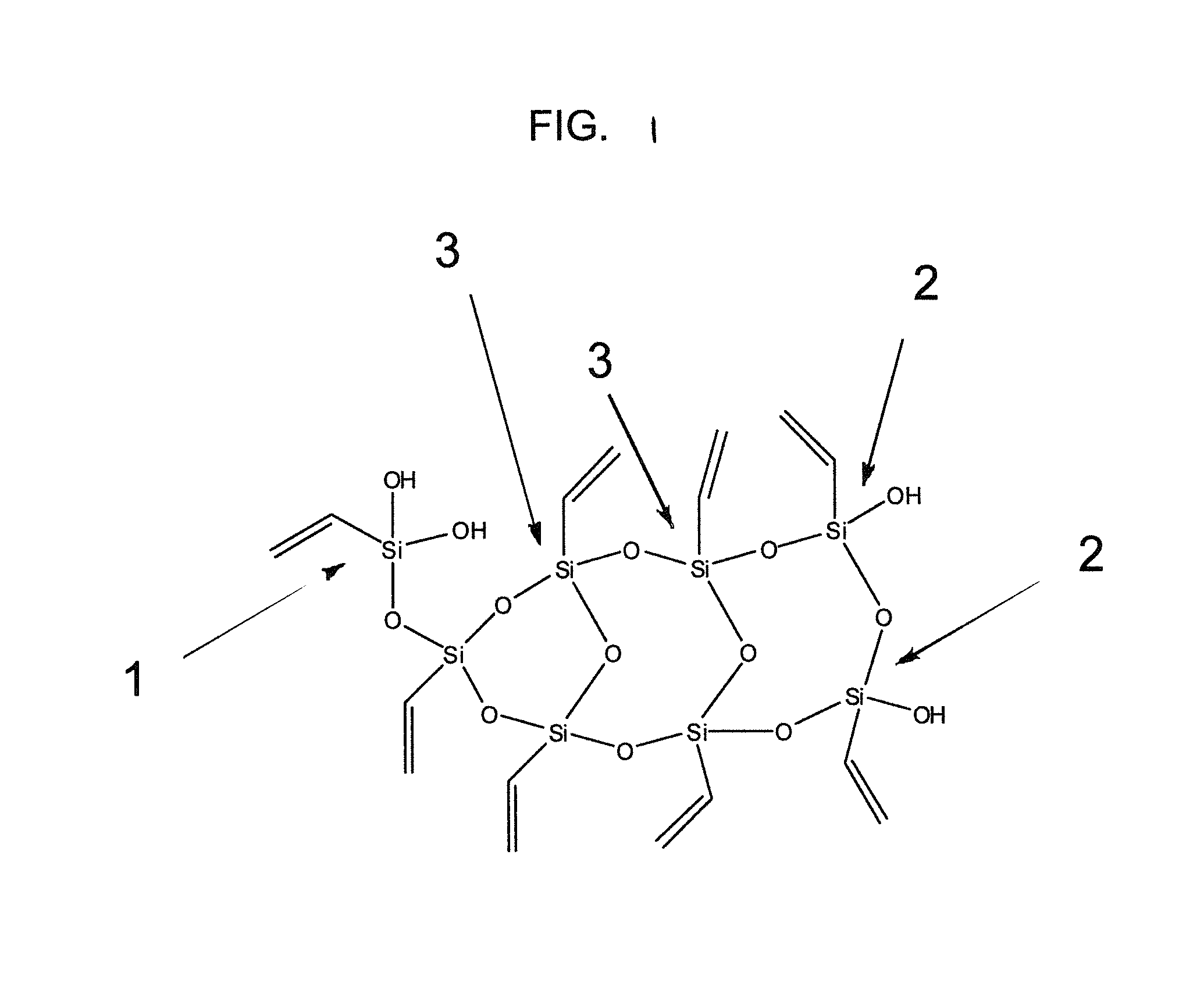

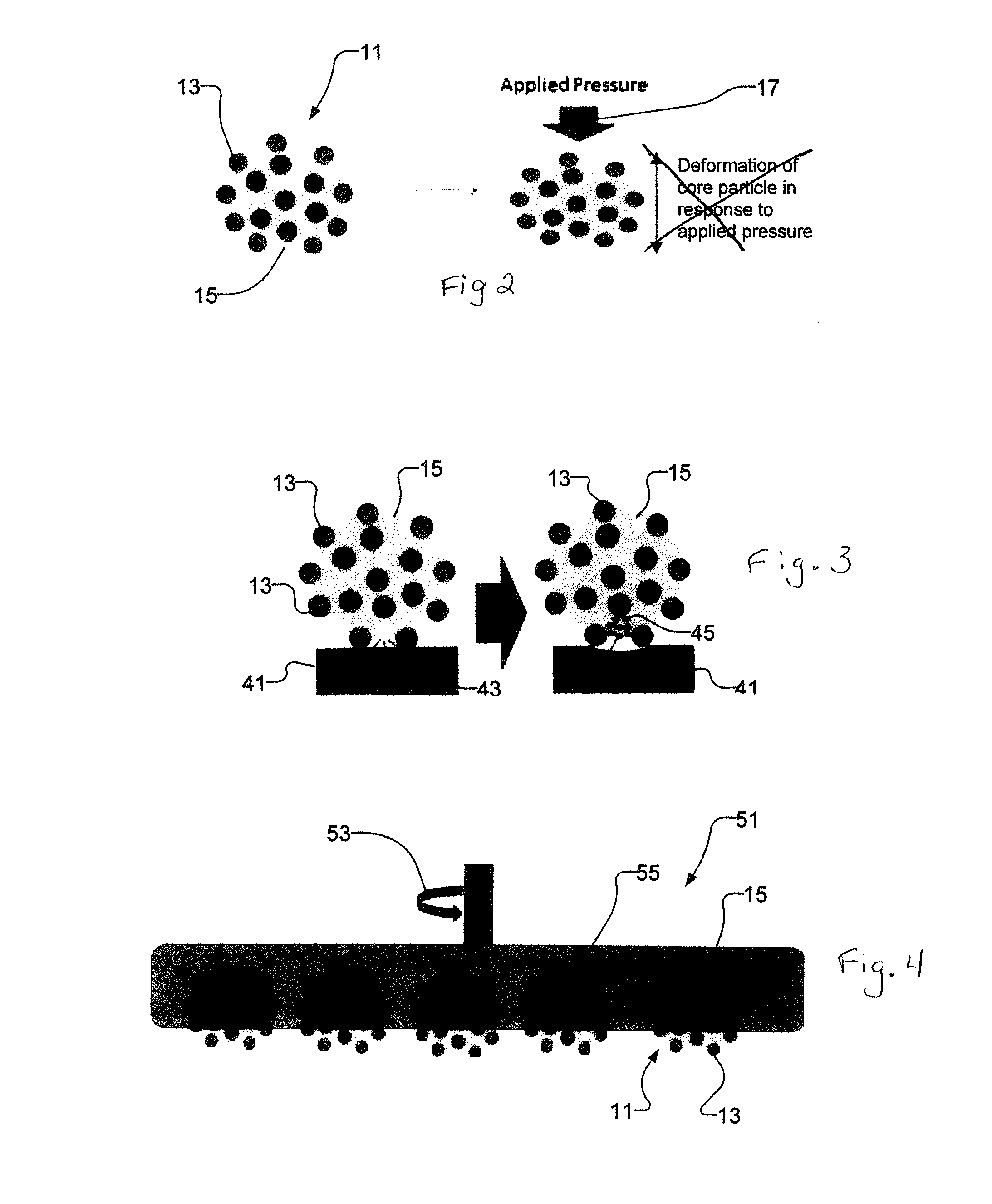

[0134]This example demonstrates the formation of organosilica-polyester composite particles in accordance with an embodiment of the invention.

[0135]38 g of the latex from Example 1 (26.4 wt % polyester+MPS) was diluted with 162 g deionized water to form a 5 wt % dispersion. 5 g of vinyltrimethoxysilane (VTMS, MW 148, 34 mmol) was dissolved in 25 g deionized water and stirred with a magnetic stir bar (300 rpm) for ˜60 min until the organic droplets were completely dissolved and a transparent solution was obtained. 1 g of 30% ammonium hydroxide solution (MW=34) was added to the diluted latex dispersion and mechanically stirred for 5 min. The VTMS solution was added over one minute and the reaction allowed to proceed for 3 hours at room temperature. A second solution of VTMS, identical to the first, was prepared and added to the reaction mixture, and the reaction was allowed to proceed for an additional 3 hours. Transmission electron microscopy of the resulting particle dispersion is s...

example 3

[0136]This example demonstrates formation of organosilica-polyester composite particles in accordance with an embodiment of the invention.

[0137]The latex of Example 1 was prepared without addition of MPS to the polymer / solvent solution. Rather, 1 g of MPS was added to 40 g of the latex (about 25 wt % polymer) and stirred for 2 hours until the MPS droplets disappeared. Then, 160 g deionized water was added to dilute the dispersion to 5 wt % polymer. A VTMS solution was prepared as in Example 2. 1 g of 30% ammonium hydroxide solution (MW=34) was added to the diluted latex dispersion and mechanically stirred for 5 min. The VTMS solution was added over one minute and the reaction allowed to proceed for 3 hours at room temperature. A second solution of VTMS, identical to the first, was prepared and added to the reaction mixture, and the reaction was allowed to proceed for an additional 5 hours. The resulting composite particles were recovered by evaporation of the solvent at room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com