Volume change compensated silicon-silicon oxide-lithium composite material having NANO silicon particles embedded in a silicon:silicon lithium silicate composite matrix, and cyclical ex-situ manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

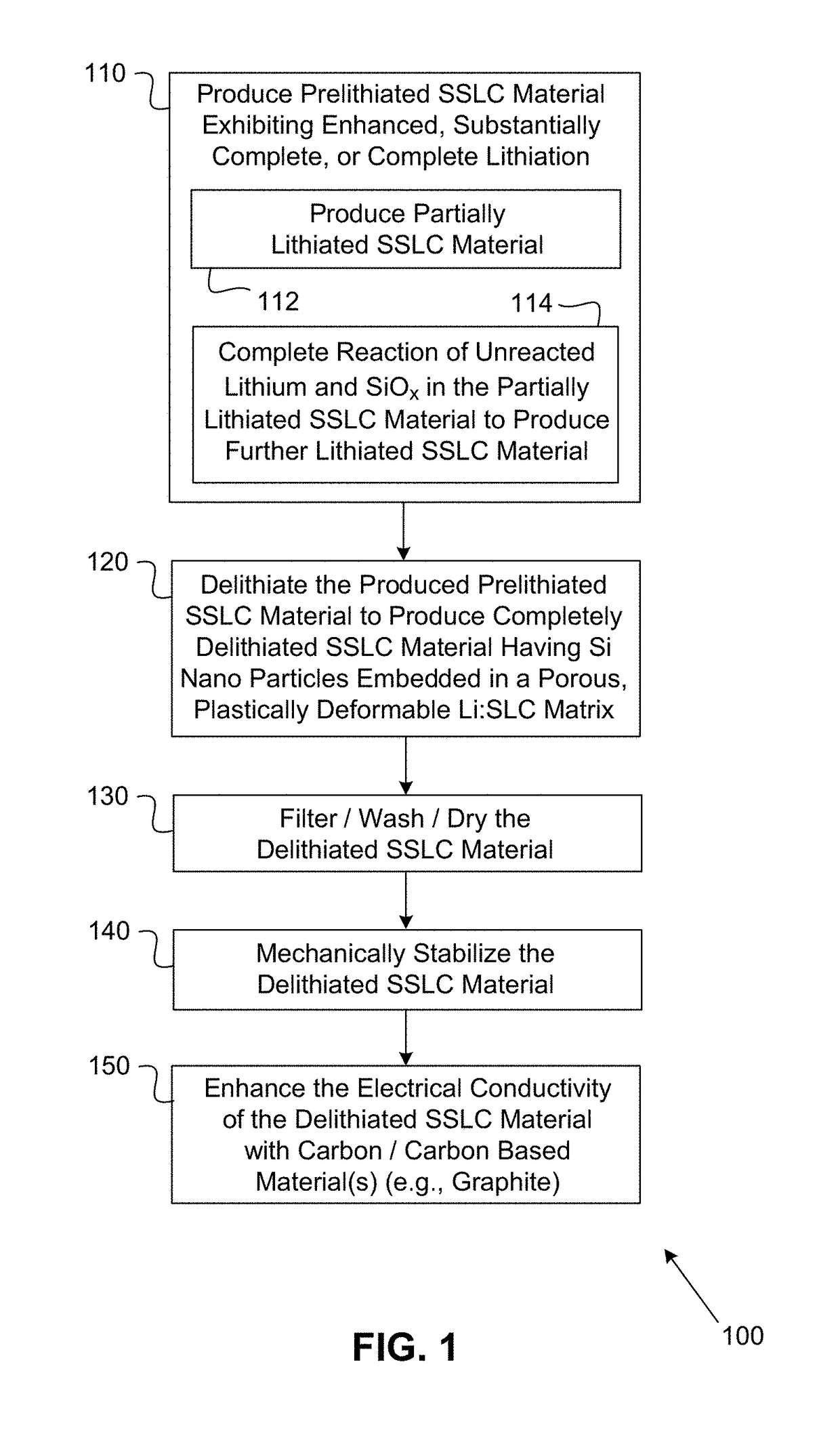

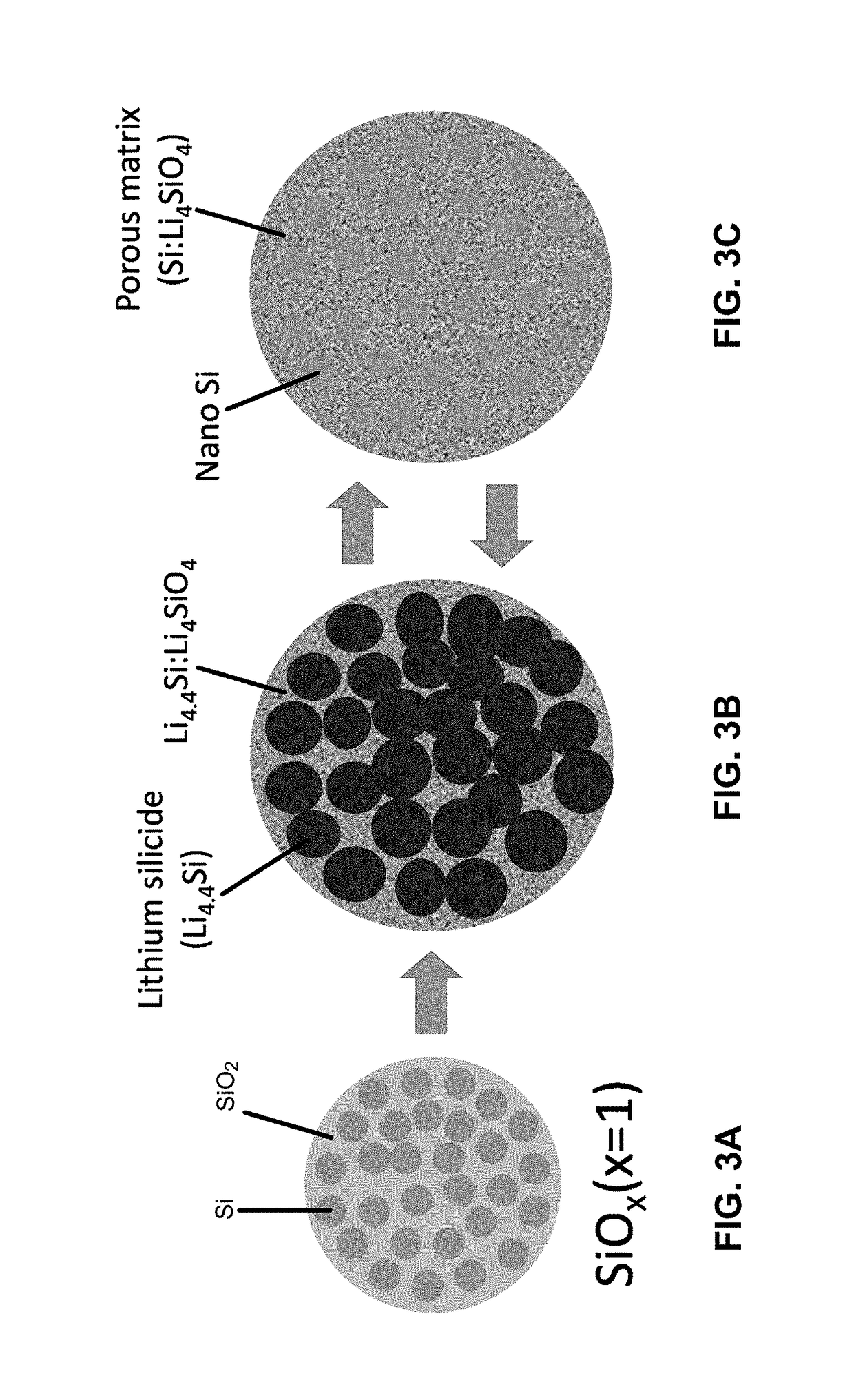

Method used

Image

Examples

example 1

[0099]Silicon oxide powder (SiOx, 0.8x is premixed with 3.8 g SLMP®) understood by individuals having ordinary skill in the relevant art. While metallic lithium is generally available in powder, foil or mass form, the use of stabilized lithium powder SLMP® (FMC Corporation) is typically preferable.

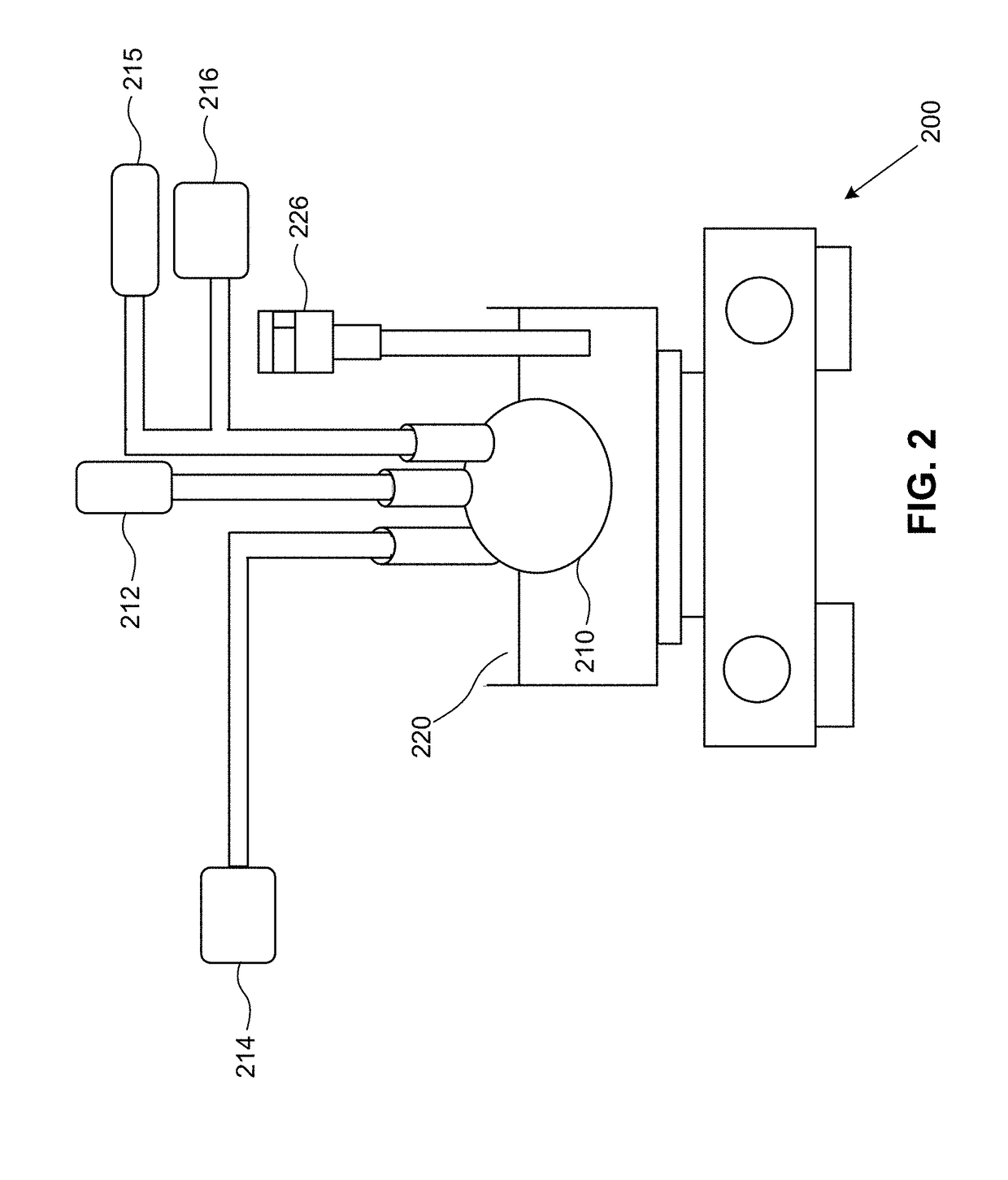

[0100]The silicon oxide and / or silicon oxide-based material premixed with metallic lithium is transferred into a ball milling container, vessel, or jar (e.g., a 50 ml or larger container); and then ball milled, i.e., mechanically mixed for reaction with lithium in a ball milling machine having an effective heat dissipation capability. The reaction container should be tightly sealed with rubber rings under an inert gas atmosphere designed for cooling control, and capable of mixing under high shear stresses. A planetary high energy ball milling machine is a good representative example ball milling machine for such milling process. For instance, a planetary ball milling machine produced by Re...

example 2

[0114]A second Example is described hereafter, which is performed in a manner analogous or substantially identical to that described above for Example 1, in a manner readily understood by individuals having ordinary skill in the relevant art in view of the description herein.

[0115]SiOx powder (SiOx, 0.8x particles and graphite powder are ball milled an additional 2 hours, thus producing a SiOx based powder, namely, SiOx / graphite powder intended for prelithiation in accordance with an embodiment of the present disclosure. Next, SLMP® powder (FMC Corporation) is added to the ball mill container, and ball milling for an additional 30 minutes leads to the partial prelithiation of the original SiOx / graphite powder, and the production of a partially prelithiated SSLC material. The partially prelithiated SiOx / graphite powder is next compressed into pellets in a conventional manner, with hexane elimination by filtration or evaporation. The pellets are then immersed in an electrolyte or a mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com