Oral Compositions and Methods of Use

a technology of oral compositions and oral cavity, applied in the field of oral care compositions, to achieve the effect of maintaining static yield stress and avoiding viscosity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0195]The examples herein detail how the viscosity over time for a composition which exhibits a problem of rapid reduction in viscosity (Run A), is compared to five compositions which show the stabilized viscosity provided by the invention (Compositions 1-5 in Table 1).

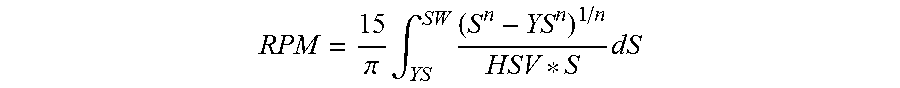

[0196]Viscosity is measured on a Brookfield HADV2 viscometer using a V74 vane spindle. This viscometer applies a user-controlled angular velocity to the spindle, typically measured in rotations per second (RPM), and reports torque on the shaft of the spindle. Viscosity is then calculated from RPM and torque as explained in the Brookfield Manual (Operating Instructions) using too conversion parameters SRC (shear rate constant) and SMC (spindle multiplier constant). The conversion parameters are defined as follows: SMC=290, SRC=0.2723. The test is performed at room temperature, and varies between 22 and 25° C. During the test, RPM of the spindle is swept from 200 to 0.5 in 12 steps, 10 seconds per step. The viscosity re...

example 2

[0201]Table 5 (below) describes the formulas of three exemplary compositions of the present invention (Compositions 9, 10 and 11) and a comparative example (Comparative Example 1).

TABLE 5CompositionCompositionComparativeComposition 91011Example IIngredientWt %GLYCERIN35.0000026.0000026.0000035.00000SORBITOL - NON-—13.0000013.00000—CRYSTAL - 70% SOLNEP PURIFIED WATER30.9047427.8247427.6247430.84874STANDARD ABRASIVE10.0000010.0000010.0000010.00000SILICASILICA-THICKENER7.000006.000006.000007.00000SMALL PARTICLE5.000005.000005.000005.00000SILICALAURYL SULFATE2.105262.105262.105262.10526GRANULESFlavor1.500001.500001.500001.50000L-ARGININE1.500001.500001.500001.50000COCAMIDOPROPYL1.250001.250001.250001.25000BETAINEZINC OXIDE1.000001.000001.000001.00000TITANIUM DIOXIDE0.750000.750000.75000—XANTHAN GUM0.600000.300000.300000.40000SODIUM CMC - TYPE———1.1000012HYDROXYETHYL-0.500000.800001.00000—CELLULOSE (HEC)*TETRASODIUM0.500000.500000.500000.50000PYROPHOSPHATEZINC CITRATE0.500000.500000.5000...

example 3

[0202]Table 6 (below) describes the results of viscosity and static yield stress evaluations performed on an exemplary composition of the present invention and a reference formula.

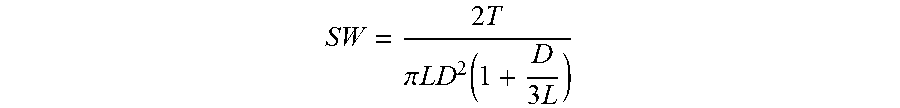

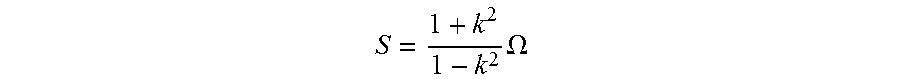

[0203]Viscosity and Yield Stress are measured on a Brookfield HADV2 viscometer using V74 vane spindle 1.176 cm in length and 0.589 cm in diameter. This viscometer applies a user-controlled angular velocity to the spindle, typically measured in rotations per second (RPM), and reports torque, T %, measured in the percentage of the maximum total torque on the shaft of the spindle. The torque, T, measured in SI units, N*m, is related to T % as reported by the above mentioned viscometer as T=1.437*10−5*T %.

[0204]The tests are performed at room temperature (22 to 25° C.). During the test 0.5 RPM of the spindle is first rotated for 400 sec and then RPM is swept from 0.5 to 200 and back to 0.5 in 12 logarithmical steps each way, 10 seconds per step. The viscosity reading is taken at RPM=1 on the decreasing RPM swe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt. % | aaaaa | aaaaa |

| wt. % | aaaaa | aaaaa |

| wt. % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com