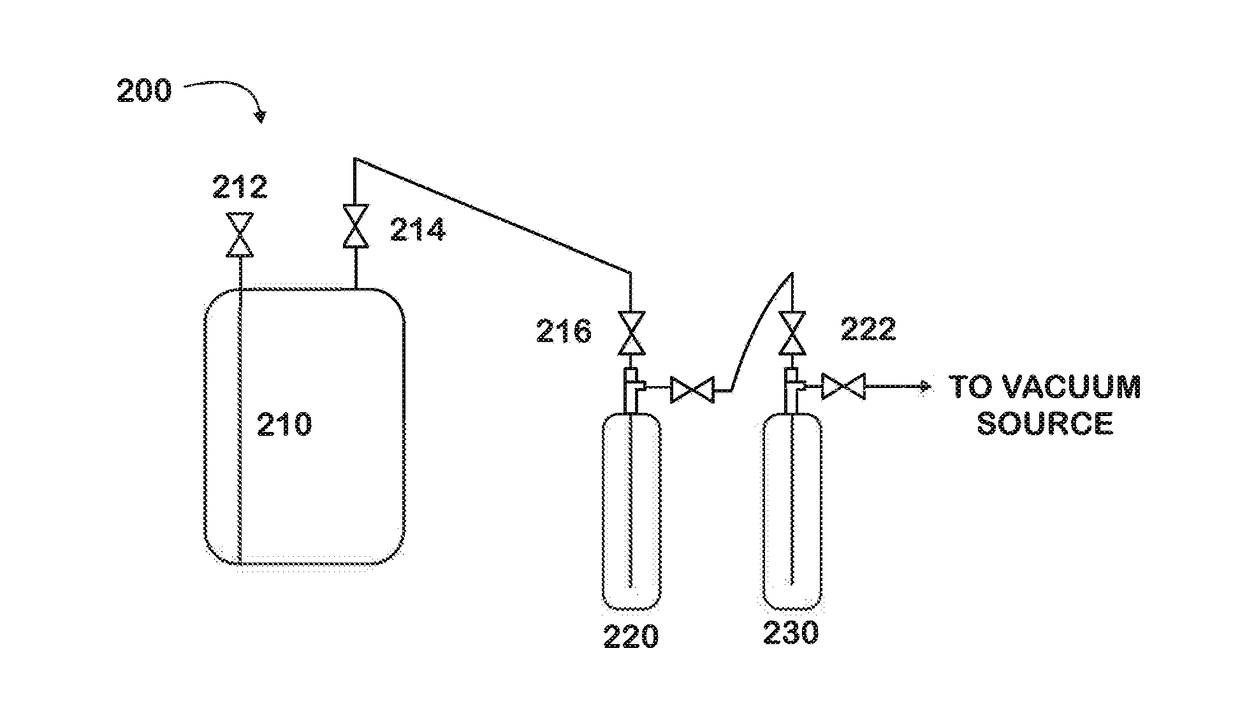

Systems and Processes for Producing Organic Acids Direct from Beta-Lactones

a technology of organic acids and betalactones, which is applied in the field of reactor systems and processes for producing organic acids directly from betalactones, can solve the problems of high reaction rate, capital intensive process, additional equipment and operating costs, etc., and achieves economic benefits and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

n of β-methyl-β-propiolactone to trans-2-butenoic acid Using a Zeolite

[0072]This Example demonstrates the production of trans-2-butenoic acid from bPL derivative using a zeolite.

[0073]A mixture of β-methyl-β-propiolactone (3.0 g) and phenothiazine (9.0 mg) is added using a needle valve to a mixture of sulfolane (40.0 g) and Zeolite Y hydrogen (20.0 g) at about 165° C. with 50 psi of carbon monoxide. Zeolite Y hydrogen (80:1 mole ratio SiO2 / Al2O3, powder S.A. 780 m2 / g) is dried under vacuum at about 100° C. for one day before use. Phenothiazine is the polymerization inhibitor used. Sulfolane is the solvent used, and is dried over 3 Å molecular sieves prior to use. β-methyl-β-propiolactone is added slowly using the needle valve over about 8.6 minutes. The reaction mixture is heated to about 170° C. to produce trans-2-butenoic acid.

[0074]The reaction is monitored by infrared spectroscopy (IR). The reaction is observed to be completed after about 3 hours, when no β-methyl-β-propiolacton...

example 2

se Conversion of β-methyl-β-propiolactone to trans-2-butenoic acid Using an H-ZSM-5

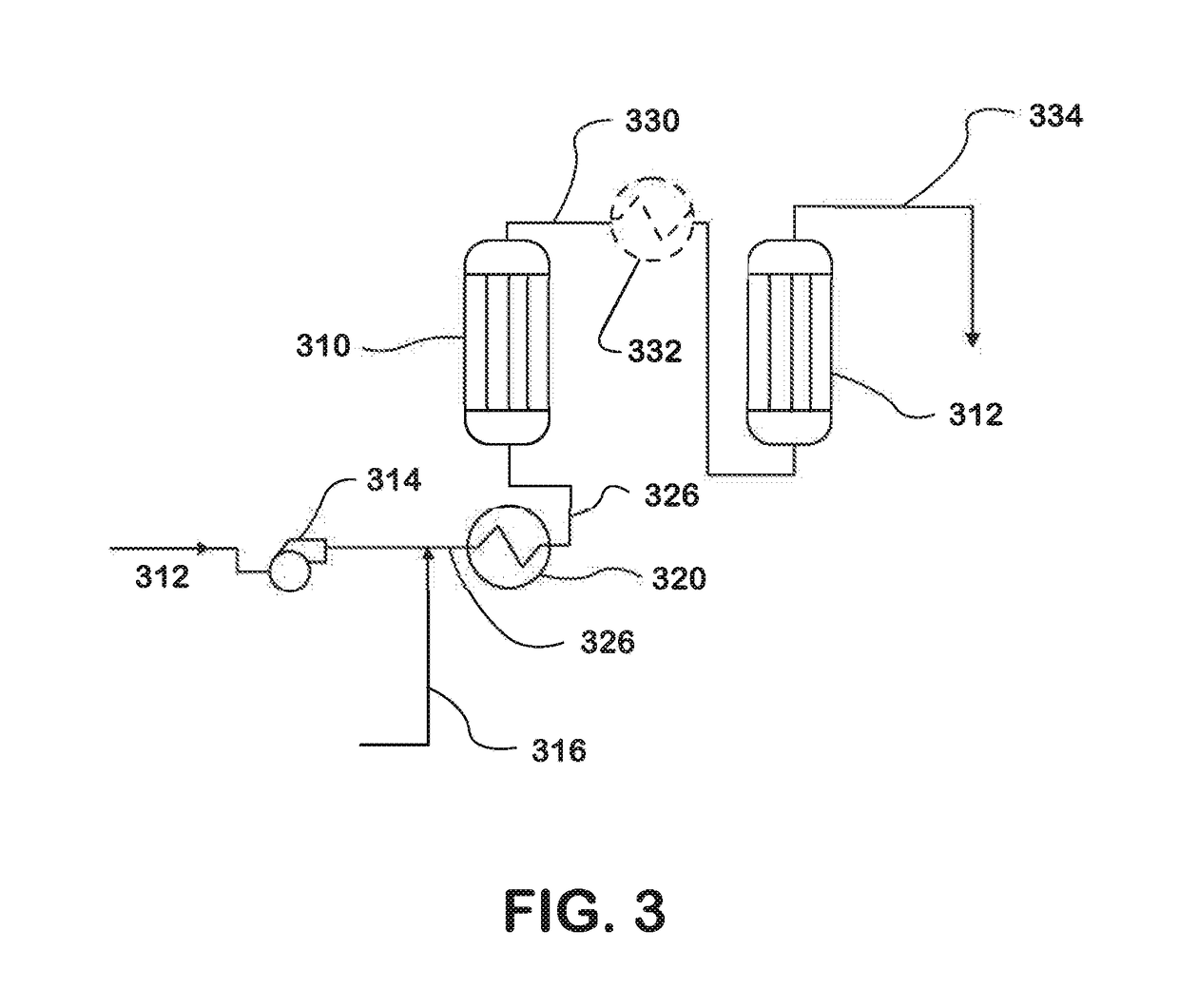

[0076]Vapor phase conversion of β-methyl-β-propiolactone to trans-2-butenoic acid is performed in packed-bed reactor using H-ZSM-5 (ACS Materials LLC, Si:Al=38, diameter 2 mm, surface area >=250 m2 / g) as a catalyst. 11 grams of H-ZSM-5 catalyst is loaded into jacketed stainless steel 316 pipe reactor (ID 0.5 inch), the catalyst is supported between glass beads columns (stainless steel wool is placed below and above glass beads). Multi-point thermocouple is inserted through the center of the reactor and hot oil is circulated through the reactor jacket to maintain the desired reactor temperature. β-methyl-β-propiolactone is fed to the reactor by means of saturator: N2 at the rate of 28 g / hr is flown into the bottom of the vessel containing liquid β-methyl-β-propiolactone at a=94° C., this results in β-methyl-1-propiolactone feed rate of 5 g / hr. The pressure of reactor and saturator is maintained at 9.5 ...

example 3

n of 3-methyloxetan-2-one to Methacrylic Acid Using a Zeolite

[0077]This Example demonstrates the production of methacrylic acid from 3-methyloxetan-2-one using a zeolite.

[0078]A mixture of 3-methyloxetan-2-one (3.0 g) and phenothiazine (9.0 mg) is added using a needle valve to a mixture of sulfolane (40.0 g) and Zeolite Y hydrogen (20.0 g) at 165° C. with 50 psi of carbon monoxide. Zeolite Y hydrogen (80:1 mole ratio SiO2 / Al2O3, powder S.A. 780 m2 / g) is dried under vacuum at 100° C. for one day before use. Phenothiazine is the polymerization inhibitor used. Sulfolane is the solvent used, and is dried over 3 Å molecular sieves prior to use. 3-methyloxetan-2-one is added slowly using the needle valve over about 8.6 minutes. The reaction mixture is heated to 170° C. to produce methacrylic acid.

[0079]The reaction is monitored by infrared spectroscopy (IR). The reaction is observed to be completed after about 3 hours, when no 3-methyloxetan-2-one is detectable by IR.

[0080]The zeolite is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com