Self-assembled melanin particles for color production

a self-assembled, color-producing technology, applied in the preparation of microcapsules, organic dyes, material nanotechnology, etc., can solve the problems of significant challenges, non-iridescent structural colors lack sufficient color saturation, useful for wide angle displays, etc., to increase the brightness and saturation of supraballs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

FDTD Simulation

[0094]A Lumerical FDTD solutions 8.15 was used to run the optical modeling. In the simulation, we created an FCC colloidal lattice with its plane (111) as X-Y plane and a plane wave light was injected down from Z direction, perpendicular to plane (111). For the simulation in FIG. 8A, we compared theoretical reflectance spectra from core-shell and homogenous nanoparticles. The homogenous nanoparticles is the same size as core-shell nanoparticles with a RI of averaged RI value of core-shell nanoparticles based on the equation,

nhomo2(Vcore+Vshell)=ncore2Vcore+nshell2Vshell (1)

[0095]We set the RI value of 1.74 for high RI material (identical to synthetic melanin, but without any absorption) and 1.45 for the low RI material (same with fused silica) in our calculations. The lattice has 30 periods along the X and Y directions and 12 periods along Z directions. We chose auto non-uniform mesh type with accuracy of 6 and a light source range of 400-800 nm (mesh...

example 2

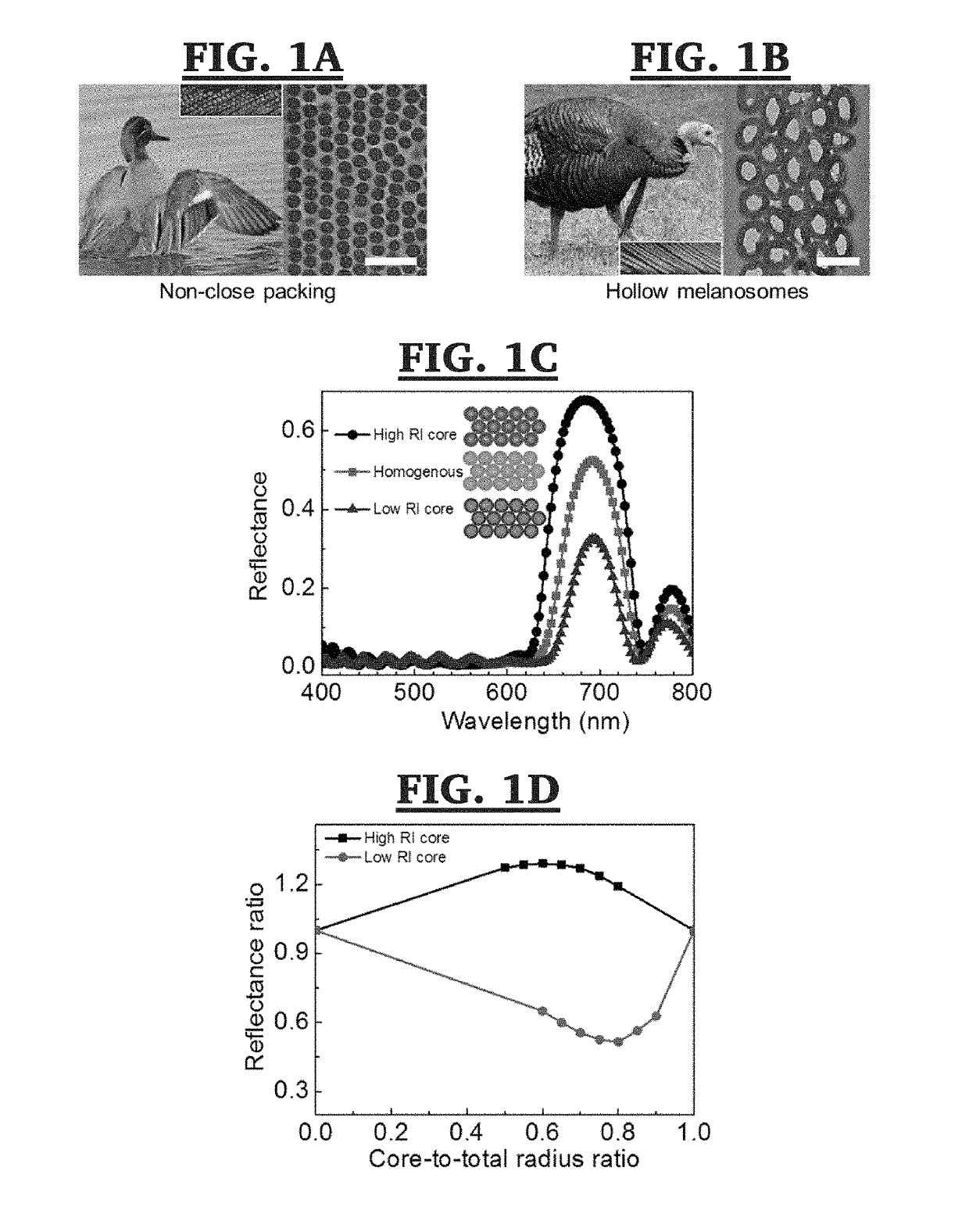

Characterization of Nanostructures in Bird Feathers

[0104]Iridescent wild turkey (M. gallopavo) breast feathers and green-winged teal (A. crecca) wing feathers were obtained from the University of Akron collection. The protocol used to prepare barbule cross sections for TEM is set forth in M. Xiao, A. Dhinojwala, M. Shawkey, “Nanostructural basis of rainbow-like iridescence in common bronzewing Phaps chalcoptera feathers.”Opt. Express 22, 14625-14636 (2014), the disclosure of which is incorporated herein by reference in its entirety. Briefly, cut feathers were dehydrated using 100% ethanol and infiltrated with 15, 50, 70, and 100% Embed 812 resin (Electron Microscopy Sciences) every 24 hours. Next, the EMbed 812 resin and samples were placed into block molds and cured at 60° C. overnight. The blocks were trimmed and then cut 80-nm-thick sections on a microtome (Leica UC6, Leica Microsystems GmbH). The sections were placed onto copper grids for TEM imaging (JEM-1230, JEOL Ltd.). (See ...

example 3

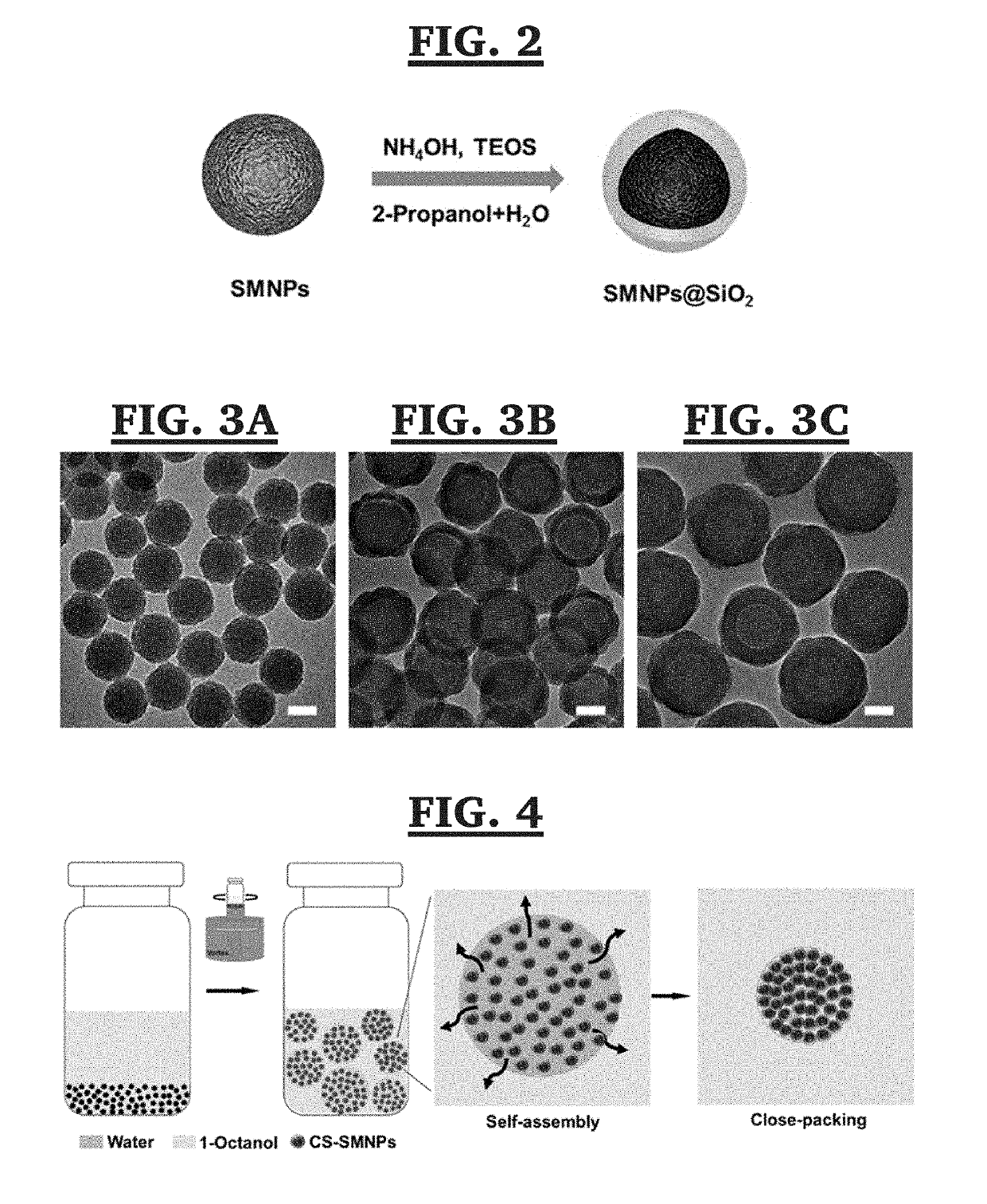

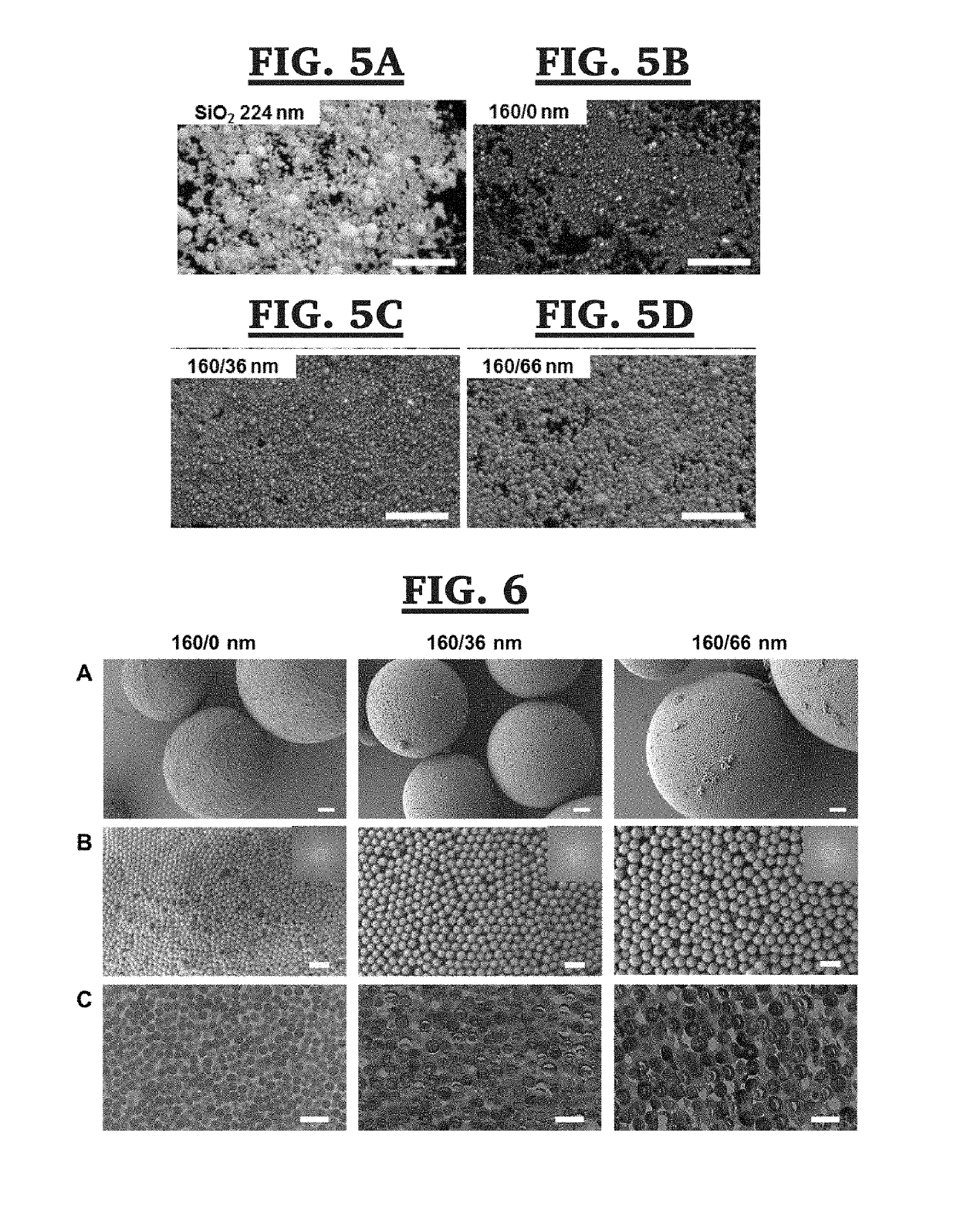

Synthesis of CS-SMNPs

[0105]Pure SMNPs were first synthesized by oxidative polymerization of dopamine molecules (Sigma-Aldrich) under base environment following the procedure described in M. Xiao, Y. Li, M. C. Allen, D. D. Deheyn, X. Yue, J. Zhao, N. C. Gianneschi, M. D. Shawkey, A. Dhinojwala, “Bio-inspired structural colors produced via self-assembly of synthetic melanin nanoparticles.”ACS Nano 9, 5454-5460 (2015), the disclosure of which is incorporated herein by reference in its entirety.

[0106]A silica shell (SiO2) was then deposited on the surface of SMNPs via the modified Stöber method as shown in W. Stöber, A. Fink, E. Bohn, “Controlled growth of monodisperse silica spheres in the micron size range.”J. Colloid Interface Sci. 26, 62-69 (1968), the disclosure of which is incorporated herein by reference in its entirety. SMNPs (3.25 mg) were first dispersed in a mixture of 5-ml 2-propanol and 0.88-ml deionized water using an ultrasonic method followed by magnetic stirring. Then, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com