Low temperature colouring method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

nt of the Methodology Using Disperse Dyes, PES and Acetone

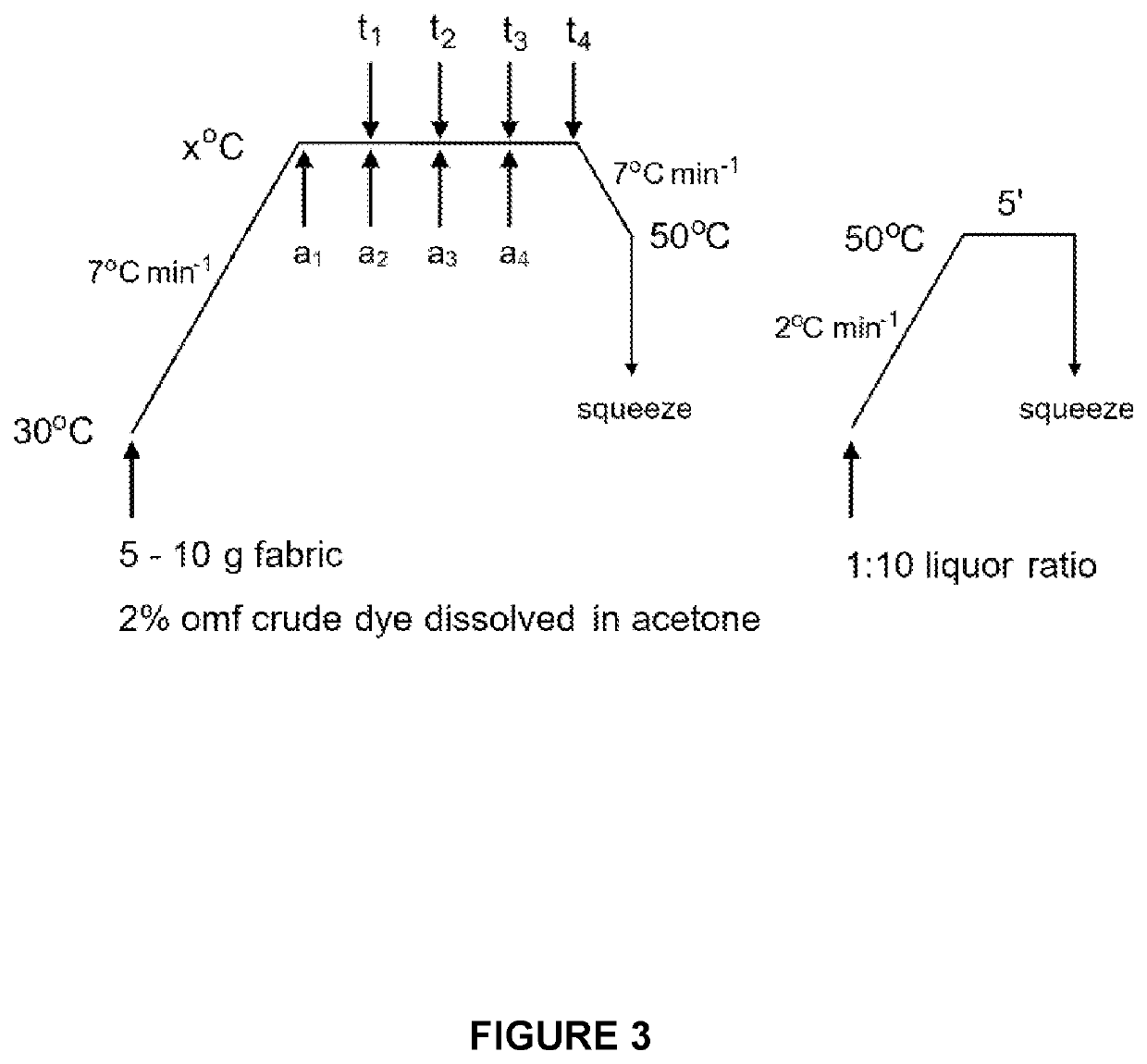

[0134]The method depicted in FIG. 3 was carried out with a1; a2; a3; a4=10 cm3 water; t1=30′; t2=30′; a3=30′; a4=30′; x=98° C.

[0135]The disperse dye was dissolved in a given volume (in this case 10 cm3) of acetone and the ensuing solution was applied to the PES fibre.

[0136]When the temperature of the dyebath reached 98° C., a volume (10 cm3) of water was added and dyeing continued for a certain period of time, after which a further 10 cm3 of water was added. This process continued until the final dyebath volume was 50 cm3, corresponding to a 1:10 liquor ratio. Thus, over the length of the dyeing process, the ratio of water:acetone was gradually increased from 0:100 at the start of dyeing to 80:20 at the end of dyeing.

[0137]Without wishing to be bound by theory, the purpose of progressively introducing water to the acetone dye solution was to gradually force the disperse dye to precipitate out of solution in a controlled manne...

example 2

[0145]Table 1 shows that 2% omf dyeings obtained using the three commercial grade dyes when applied using the HT method (i.e. 130° C.) displayed very good fastness to washing at 60° C., as expected; visual inspection also showed the impressive depths of shade of the dyeings after wash fastness testing. The results presented in Table 1 also reveal that the corresponding dyeings which had been produced using crude grade samples of the three dyes employing the precipitation dyeing method of the invention at 98° C. for 20 min displayed essentially the same high level of wash fastness. The latter findings are impressive when it is recalled that the colour strength of the 98° C. dyeings were much greater than that of their 130° C. counterparts. Thus, as expected, the manner by which the disperse dyes were applied (ie differences in dyeing temperature, dyeing duration and acetone) had no effect on wash fastness.

TABLE 1fastness of 2% omf dyeings on PES produced using the HT method (commerci...

example 3

rics and Other Classes of Dyes

[0147]The methods of the invention can also be used to dye other substrates using other dye types. The following example describes the dyeing of wool, silk and polyamide substrates with acid dyes and a disperse dye.

[0148]The general method used throughout this example is shown in FIG. 9. A Roaches Pyrotec S dyeing machine) was used. 0.1 g of commercial dye was dissolved in 10 cm3 acetone and the ensuing solution was placed in a 300 cm3 capacity dye tube, followed by 5 g of fabric. The sealed dye tube was heated to 85° C. and then 10 cm3 of water was injected into the dyeing tube. A further total of 40 cm3 of water was injected at time intervals, as shown in FIG. 9. The total dyeing time at 85° C. was 20 min.

[0149]Both non-metallised acid (Erionyl Red A-28F (Huntsman)) and 1:2 pre-metallised acid dyes (Supralan Yellow 4GL (Dystar); Lanaset Yellow 2R (Huntsman) and Neutrilan Yellow A-3R (Yorkshire)) were applied to wool, silk and PA fabrics using the dyei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Polarity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com