Electrolytic copper foil and electrode and lithium-ion cell comprising the same

a technology electrode, which is applied in the field can solve the problems of electrolytic copper foil being unable to be subsequently used to produce electrodes of lithium-ion cells, unable to achieve the effect of reducing the warpage or reducing the warpage of electrolytic copper foil, and optimizing the charge-discharge cycle life performance of lithium-ion cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 to 9

pper Foils

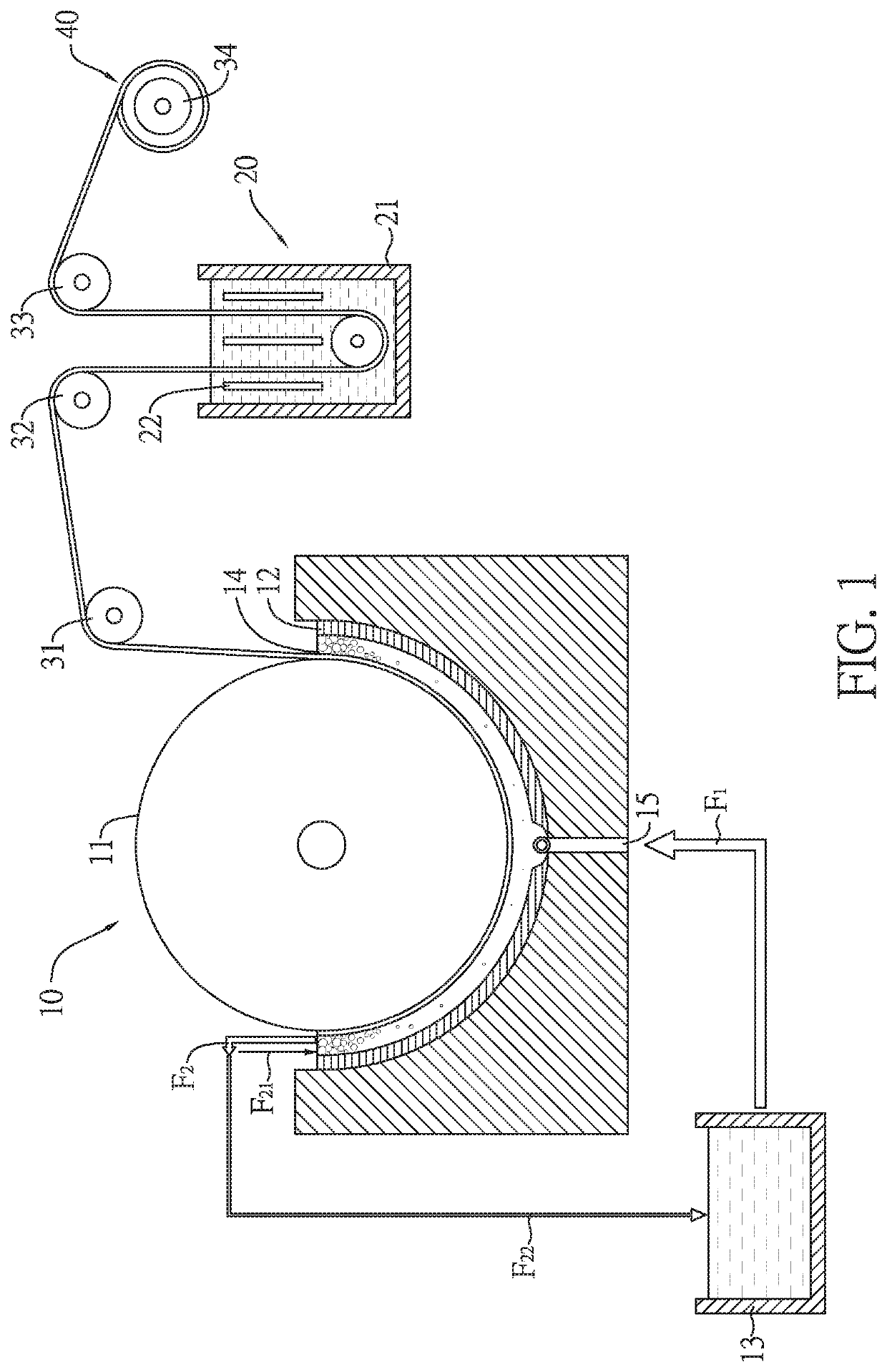

[0028]Electrolytic copper foils of Examples 1 to 9 were each produced by the production apparatus shown in FIG. 1 and through a substantially identical process comprising an electrodeposition step and an anti-tarnish treatment step in a sequential order.

[0029]As shown in FIG. 1, the production apparatus for producing electrolytic copper foils comprises an electrodeposition device 10, a surface treatment device 20, and a series of guide rollers. The electrodeposition device 10 comprises a cathode drum 11, a dimensionally stable anode 12, an electrolyte tank 13, a copper electrolyte 14, and a feed pipe 15. The cathode drum 11 is rotatable and a surface thereof is optionally mechanically polished by a buff (not shown). The dimensionally stable anode 12 is positioned below the cathode drum 11 and substantially surrounds the lower half of the cathode drum 11. The cathode drum 11 and the dimensionally stable anode 12 are spaced apart from each other to accommodate the copper ele...

examples 1a to 9a

and Comparative Negative Electrodes

[0076]The two opposite outermost surfaces of each of the electrolytic copper foils of Examples 1 to 9 and Comparative Examples 1 to 9 were coated with negative electrode slurry containing a negative electrode active substance to produce a negative electrode for a lithium-ion cell.

[0077]Specifically, the negative electrode could be substantially produced by the following steps.

[0078]First, 100 g negative electrode active material and 60 g solvent (N-methyl-2-pyrrolidone (NMP)) were mixed at a solid-liquid ratio of 100:60 to prepare the negative electrode slurry. Based on the total weight of the negative electrode active material, the negative electrode active material comprised:

[0079]93.9 wt % negative electrode active substance (Mesophase Graphite Powder, MGP);

[0080]1 wt % conductive additive (conductive carbon black, Super P®);

[0081]5 wt % solvent-based adhesive (polyvinylidene difluoride, PVDF 6020); and

[0082]0.1 wt % oxalic acid.

[0083]Next, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com