Method of manufacturing an electromagnetic wave shielding film comprising an electromagnetic wave shielding layer

a technology of electromagnetic shielding film and electromagnetic wave shielding layer, which is applied in the direction of coatings, liquid surface applicators, pretreatment surfaces, etc., can solve the problems of increasing electromagnetic wave pollution in everyday life, malfunction or system errors, diseases in the human body, etc., to improve electromagnetic wave shielding efficiency, high electromagnetic wave shielding performance, and the effect of high flatness ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

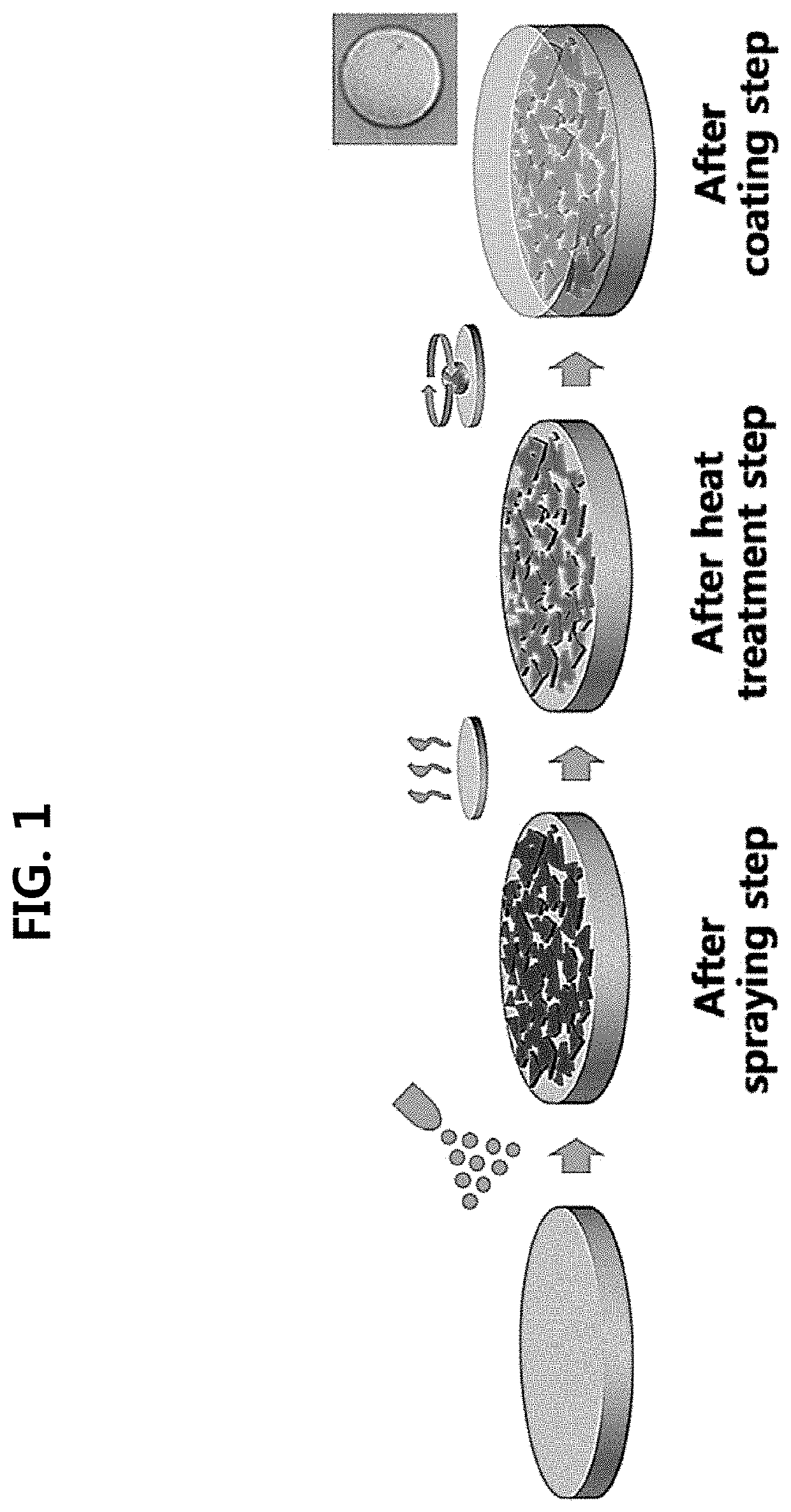

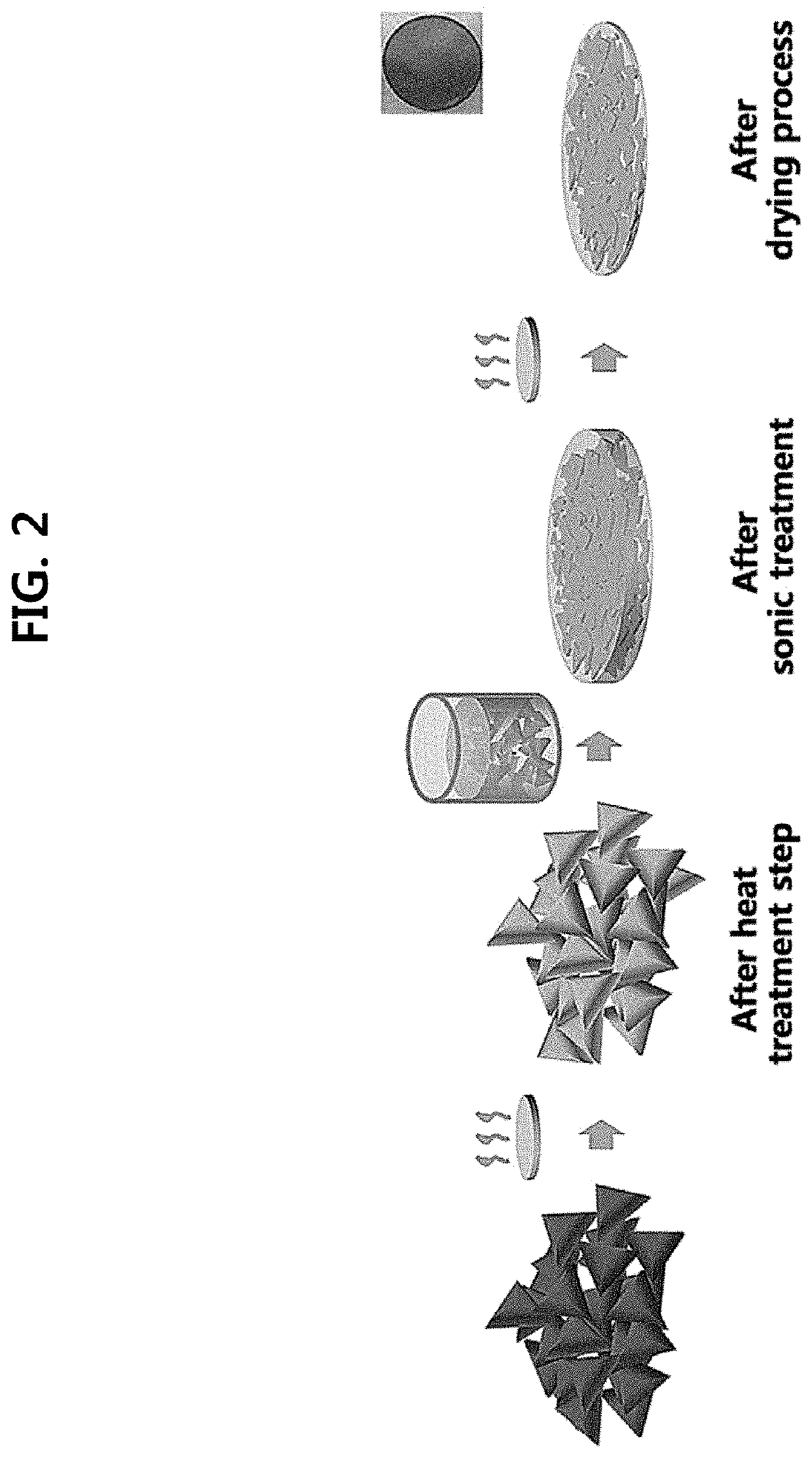

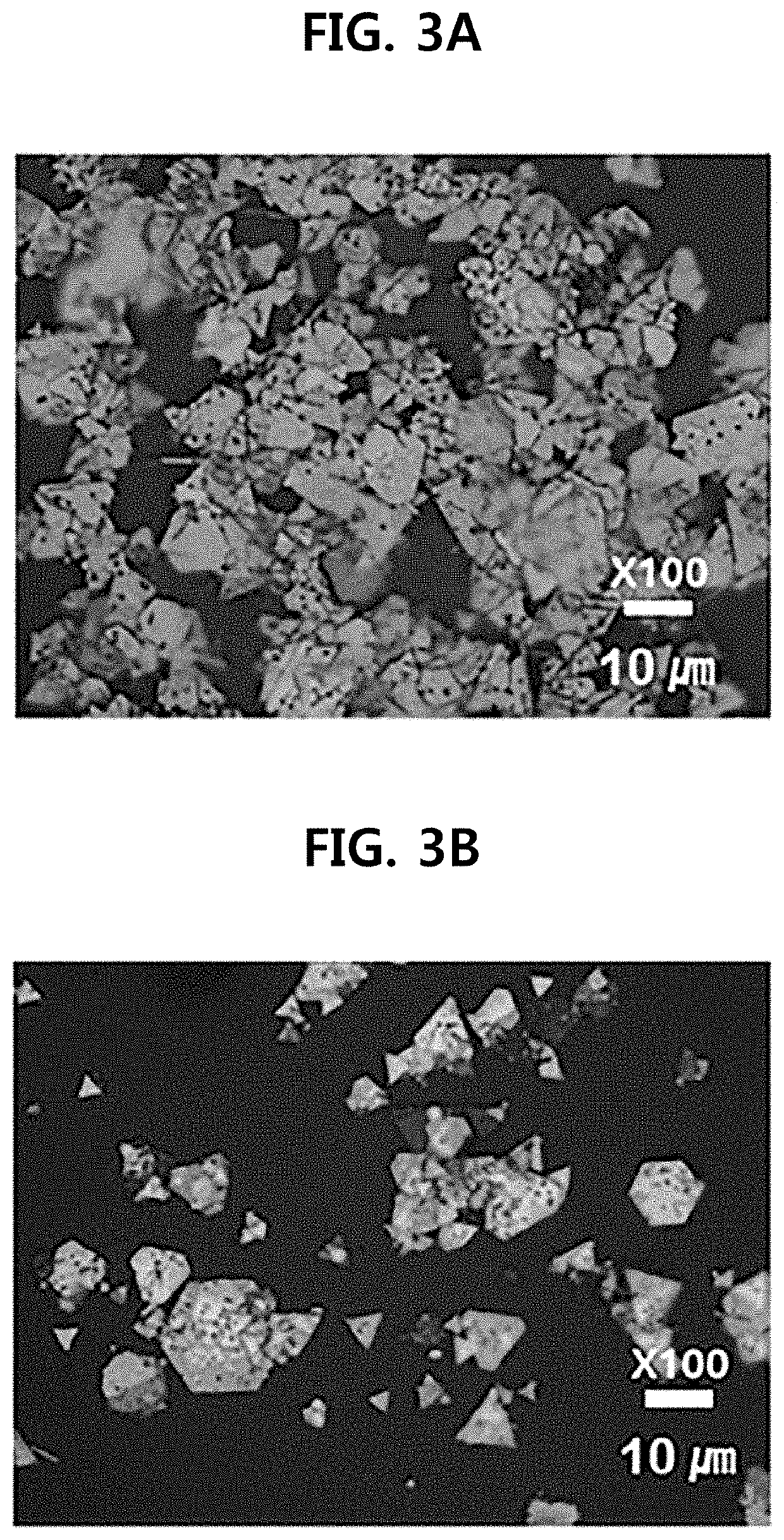

[0158]A mixed solution of 60 ml of chloroform in which 0.2 g of copper nanoplate (FIG. 3A to FIG. 4) was dispersed was prepared, and a polyimide film having a thickness of 100 μm was cut into a size of 2 cm×2 cm. Thereafter, the polyimide film was placed on a hot plate at 60° C., and a mixed solution in which the copper nanoplate was dispersed was spray-coated on the upper surface of the polyimide film 10 times in total by spraying 1 ml for each time. And then it was subjected to a heat treatment for one hour in a furnace at 250° C. in which argon / hydrogen flowed at a ratio of 95:5 to manufacture an electromagnetic wave shielding layer. Thereafter, the surface protective layer (SU-8) was coated on the electromagnetic wave shielding layer under the condition of 500 rpm / 5 s-2000 rpm / 30 s, followed by heat treatment for 3 minutes and 30 seconds on a 95° C. hot plate, UV treatment for 3 minutes, and heat treatment for 4 minutes and 30 seconds on a 95° C. hot plate to manufacture an elec...

example 2-5

[0159]The same process as in Example 1 was carried out except that the copper nanoplate spray coating process was carried out 2 times, 4 times, 6 times, and 8 times with 1 ml per each time to manufacture the electromagnetic wave shielding film according to Examples 2 to 5 (Example 2: 2 times, Example 3: 4 times, Example 4: 6 times, Example 5: 8 times).

example 6

[0160]The same process as in Example 3 was carried out except that a heat treatment was performed for one hour in a 200° C. furnace in which argon and hydrogen flowed at a ratio of 95:5 between the copper nanoplate spray coating and the SU-8 coating process to manufacture the electromagnetic wave shielding film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com